A pressure fault detection system and method for a servo press

A servo press and fault detection technology, applied to presses, manufacturing tools, etc., can solve problems such as failure to detect abnormal pressure states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention are given below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all belong to the protection scope of the present invention.

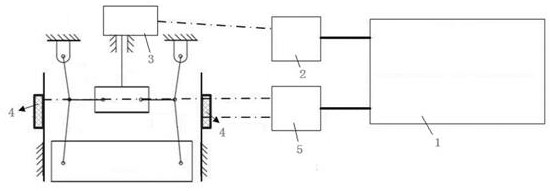

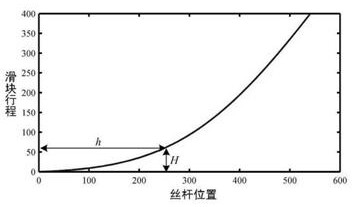

[0022] The pressure failure detection system of the servo press of the present invention includes a servo press, the servo driver 2 is connected to the whole machine control system 1 of the servo press, the servo driver 2 obtains power from the power grid, and is connected to the servo motor 3 through a cable to drive the servo The motor 3 rotates, and the servo motor 3 connects the screw mechanism and the connecting rod mechanism through a rigid structure such as a coupling. Blocks move up and down. The track on which the slider runs is installed on the four side columns of the servo press, and pressure sensors 4 are installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com