A belt roaster and its method for controlling and detecting the over-wet layer in the drum drying section

A technology of belt roasting machine and dry section, which is applied in the direction of furnace control device, furnace material, furnace, etc. It can solve the problems of increasing the pressure loss of the material layer, the flattening of the soft ball, and the high power consumption of the fan, and achieve the effect of eliminating the over-humidity layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The following equipment is used for processing, with an annual production scale of 4 million tons of oxidized pellets.

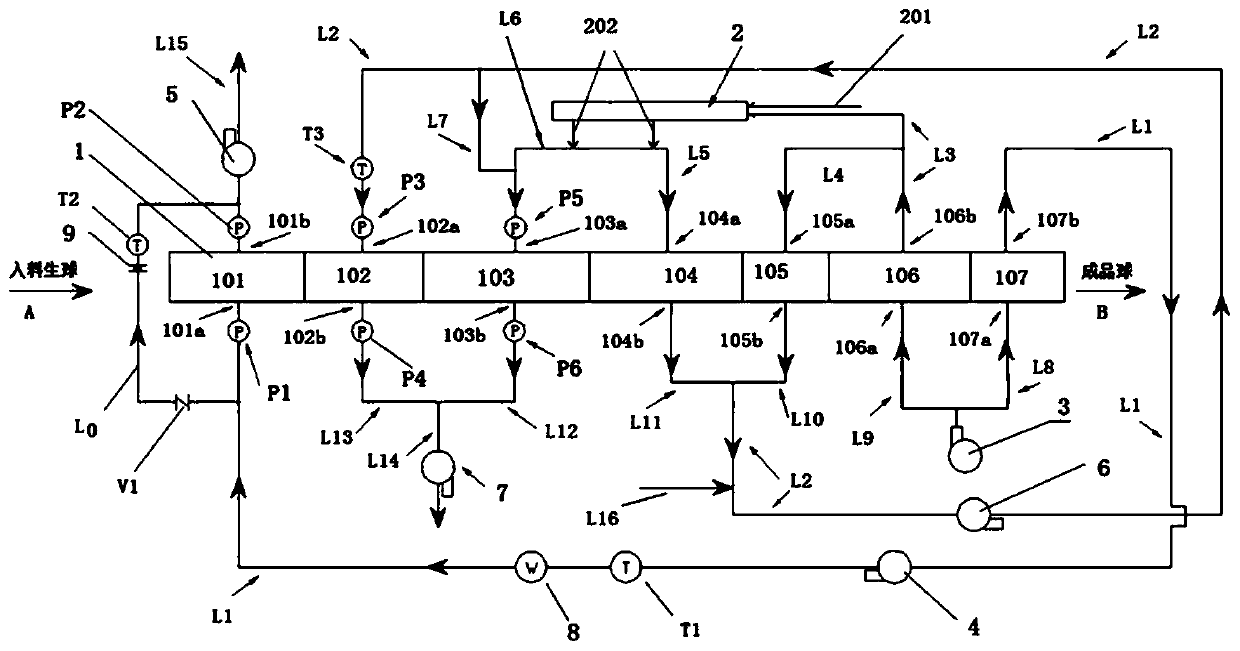

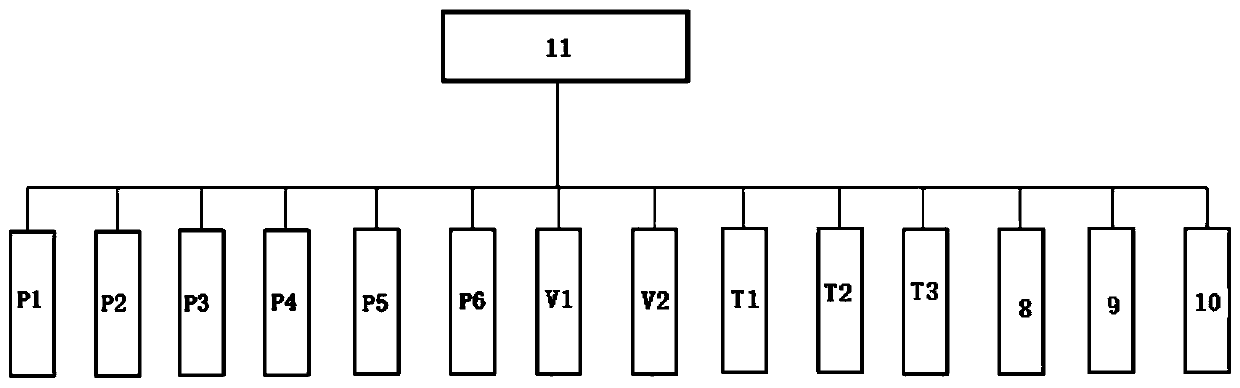

[0101] A belt roaster, which includes a belt roaster body 1 and a belt roaster combustion heating system 2, and, according to the process direction, the belt roaster body 1 is sequentially provided with a drum drying section 101, a draining section 102, Preheating section 103, roasting section 104, soaking section 105, first cooling section 106 and second cooling section 107, the combustion heating system 2 includes a combustion chamber, a gas pipeline 201 connected to the combustion chamber, and a combustion system air supply pipeline 202 ;

[0102]Wherein the air outlet 107b of the second cooling section 107 is connected to the air inlet 101a of the drying section 101 via the first pipeline L1, the eleventh pipeline L11 drawn from the air outlet 104b of the roasting section 104 and the air outlet from the soaking section 105 Both the tenth pipeline...

Embodiment 2

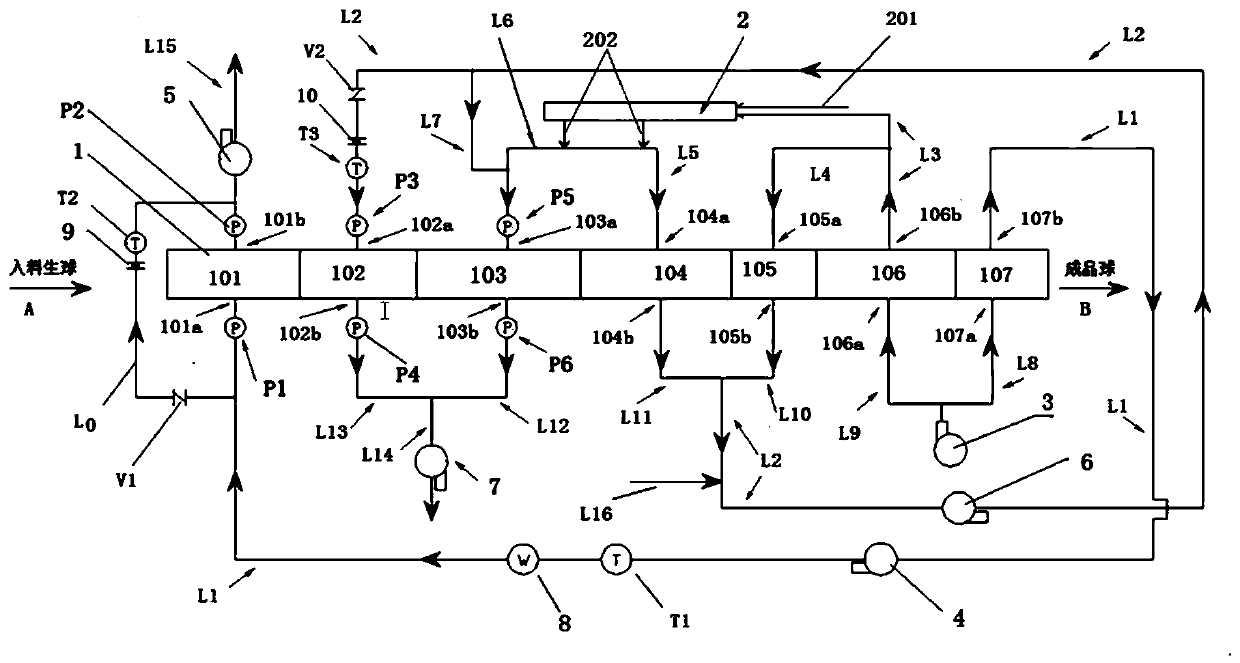

[0117] Repeat Example 1, just monitor the temperature detected by the bypass temperature detection device T2 and the flow rate detected by the bypass flow detection device 9, calculate the calorific value that needs to be added to the draining section 102 according to the heat balance, and measure the intake air temperature according to the draining section. The temperature detected by the device T3 adjusts the air intake regulating valve V2 of the draining section. In this embodiment, the value range of k is 1-30Pa.

[0118] The heat balance calculation process is: according to the heat balance, the heat added to the drain section must be equal to the heat lost by the bypass circuit of the dry section, that is:

[0119] Q 抽干 =Q 旁通 =W 旁通 ×T 旁通 ×C 旁通

[0120] Among them: W 旁通 ——The flue gas flow rate of the bypass circuit

[0121] T 旁通 ——The flue gas temperature value of the bypass circuit

[0122] C 旁通 ——The flue gas specific heat capacity of the bypass circuit.

Embodiment 3

[0124] Embodiment 1 is repeated, except that in this embodiment, the value of k ranges from 1 to 20 Pa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com