Quantitative assessment method and system of coal seam stability

A quantitative evaluation and stability technology, applied in the field of coal mine exploration, can solve the problems of cumbersome calculation, heavy statistical workload, and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

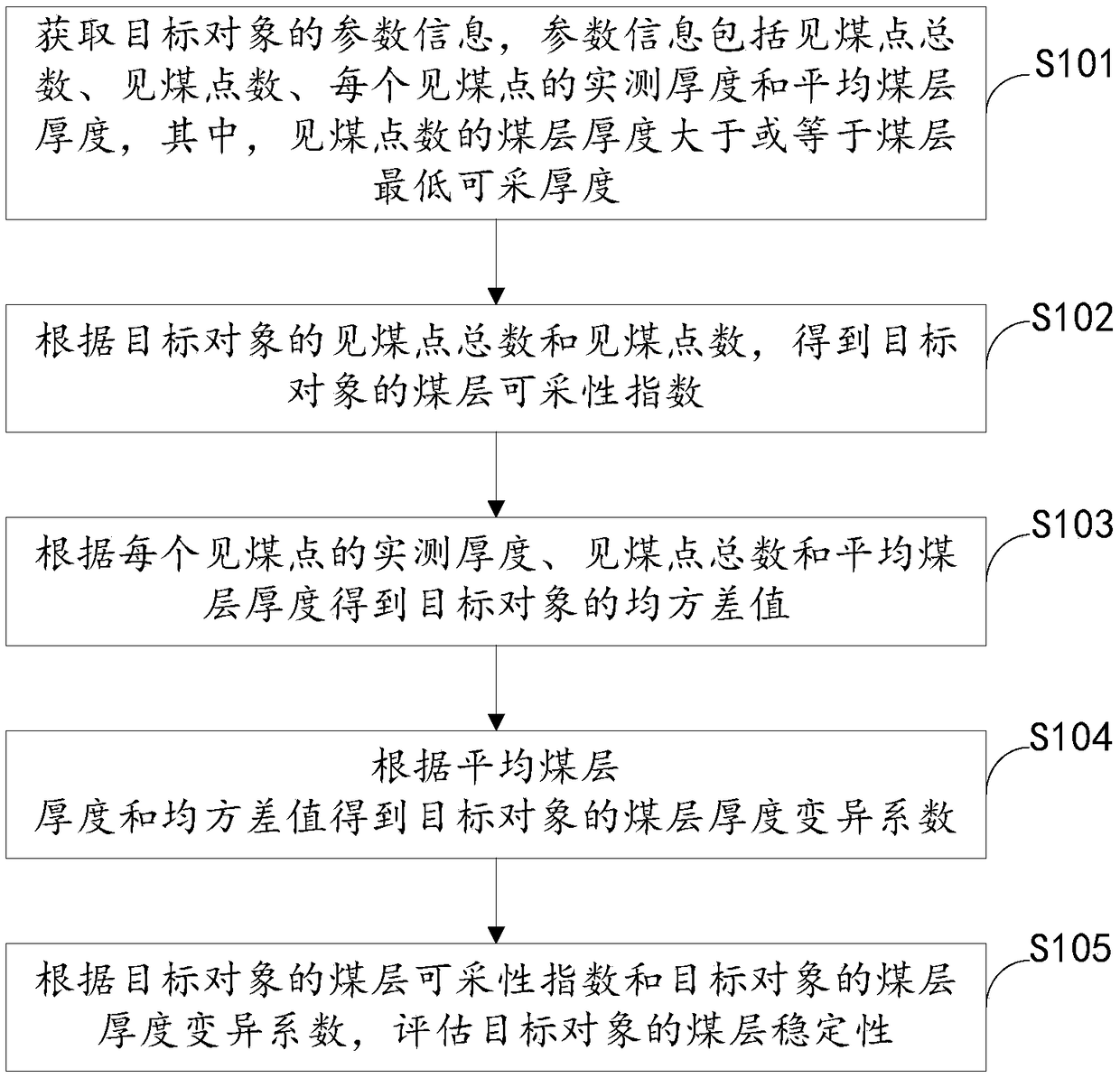

[0061] figure 1 It is a flow chart of the quantitative evaluation method for coal seam stability provided by Embodiment 1 of the present invention.

[0062] refer to figure 1 , the method includes the following steps:

[0063] Step S101, obtain the parameter information of the target object, the parameter information includes the total number of coal sight points, the number of coal seam points, the measured thickness of each coal seam point and the average coal seam thickness, wherein the coal seam thickness of the coal seam number is greater than or equal to the minimum recoverable coal seam thickness;

[0064] Step S102, according to the total number of coal sighting points and the number of coal sighting points of the target object, the coal seam recoverability index of the target object is obtained;

[0065] Step S103, obtaining the mean square error value of the target object according to the measured thickness of each coal-seeing point, the total number of coal-seein...

Embodiment 2

[0088] The Qinan Coal Mine of Huaibei Mining Co., Ltd. is located at the southern turning point of the Sunan syncline in the Huaibei mining area. It is a large-scale mine with a design capacity of 1.8 million t / a. The 82 mining area is the first middle coal formation mining area in the south wing of the mine. Now collect and sort out 82 mining areas that have been constructed and revealed 7 2 There are 39 coal seam drilling holes, according to the coal seam stability evaluation index (as shown in Table 1), for 7 2 Coal seam stability evaluation calculation.

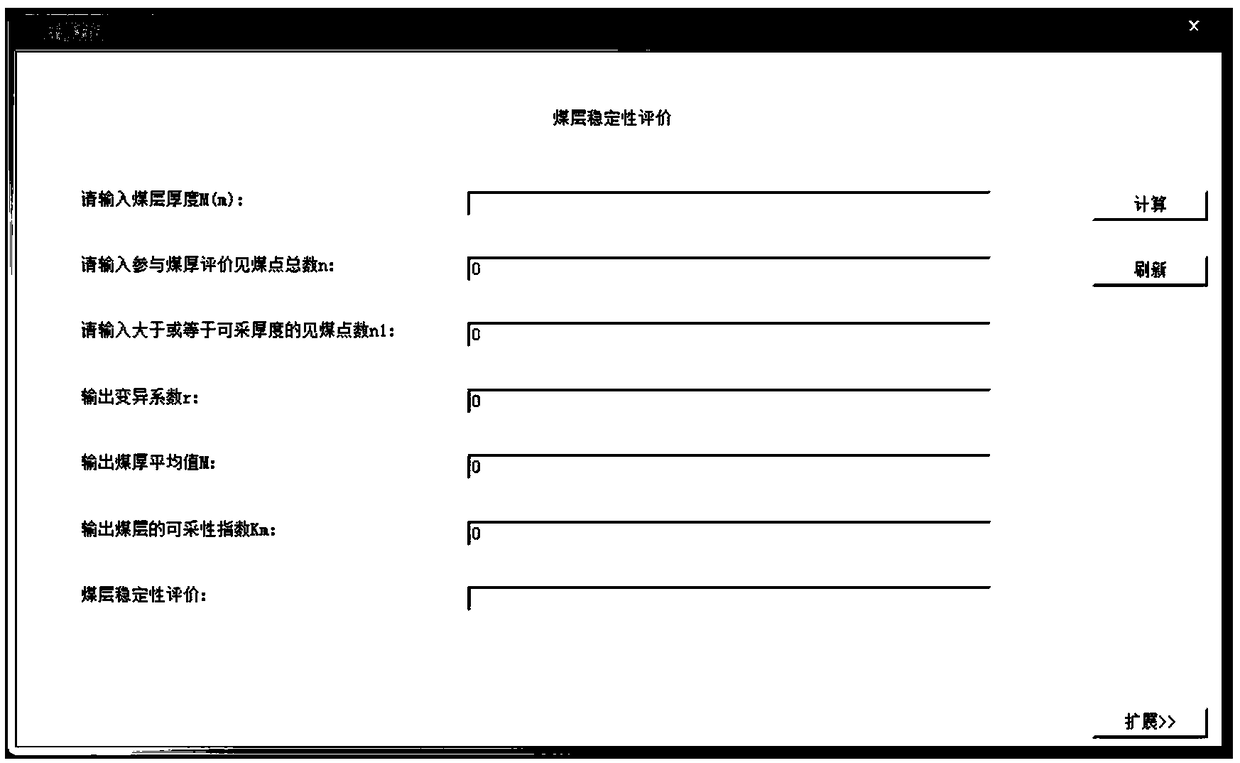

[0089] Open the coal seam stability evaluation application, such as image 3 As shown, follow the prompts to enter the measured thickness of each known coal spot in turn, press the space bar once for each coal spot, and press the Tab key or click the mouse to change the line after recording the measured thickness of all coal spots; Then enter the total number of coal sight points and the number of coal sight points in t...

Embodiment 3

[0091] Figure 5 It is a schematic diagram of a quantitative evaluation system for coal seam stability provided by Embodiment 3 of the present invention.

[0092] refer to Figure 5 , the system includes an acquisition unit 10 , a first calculation unit 20 , a second calculation unit 30 , a third calculation unit 40 and an evaluation unit 50 .

[0093] The acquisition unit 10 is used to acquire the parameter information of the target object. The parameter information includes the total number of coal-seeing points, the number of coal-seeing points, the measured thickness of each coal-seeing point and the average coal seam thickness, wherein the thickness of the coal seam with the number of coal-seeing points is greater than or equal to the coal seam The minimum recoverable thickness;

[0094] The first calculation unit 20 is used to obtain the coal seam recoverability index of the target object according to the total number of coal sight points and the number of coal sight p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com