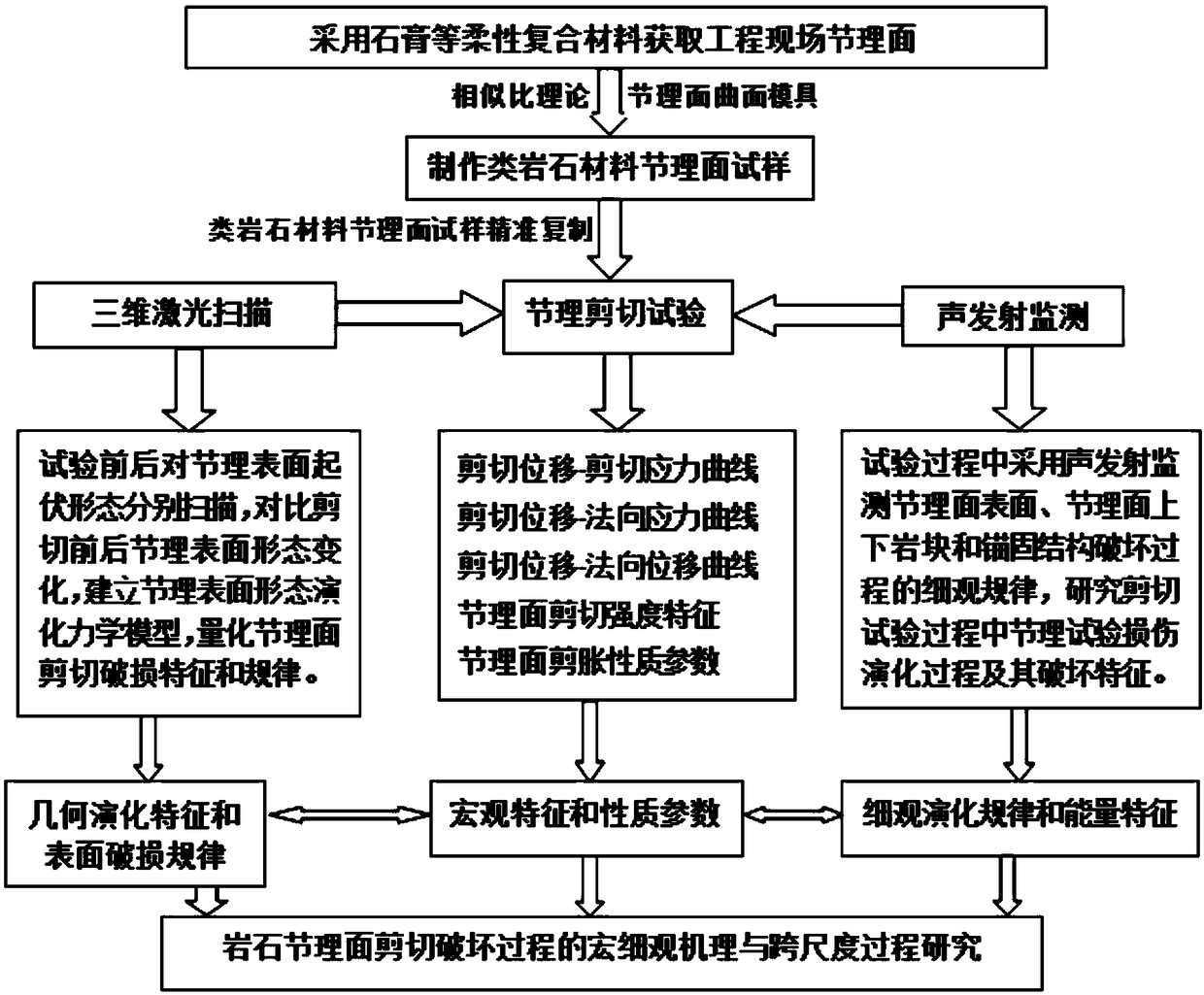

Analysis method for studying rock joint surface shearing damage process and test system

A technology of rock joints and shear failure, which is applied in the direction of applying stable shear force to test the strength of materials, analyze materials, and measuring devices, etc. It can solve the problem of single shear failure process of joint surfaces, unable to continuously monitor and accurately obtain natural joints Deformation and failure laws and eigenvalues within the surface, systematic research on the shear failure process of unfavorable rock joint surfaces, etc., to achieve the effect of accurate positioning and promotion of displacement and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

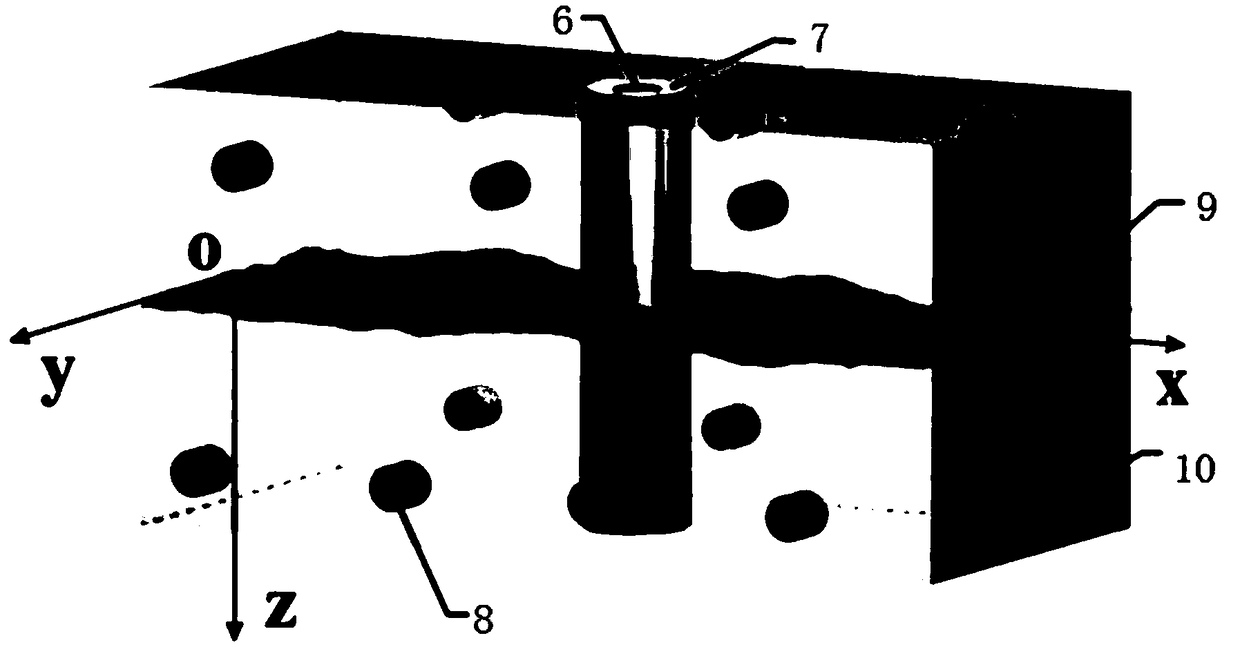

[0052] The embodiment of the present application provides a test system for studying the shear failure process of rock joint surfaces. The test system includes: joint surface laser scanner, joint shear box, rock joint shear loading structure, joint surface shear failure process acoustic launch monitor.

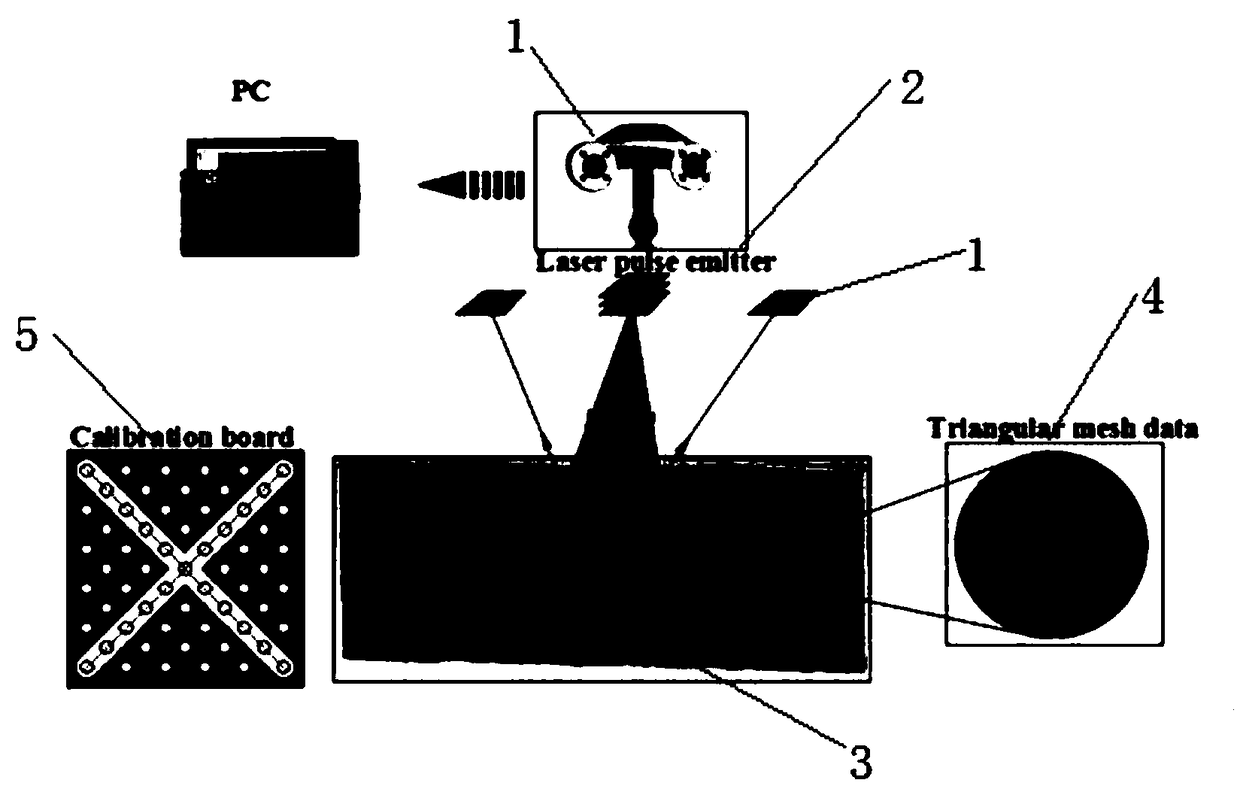

[0053] The joint shear box is used to place the specimen.

[0054] The joint surface laser scanner is used to perform laser scanning on the rock joint surface to obtain the characteristic information of the joint surface morphology. Before the acquisition of the joint surface morphology, the laser scanner needs to be calibrated first, and the scanning can be performed after optimization. The scanning mainly calculates the distance by the time from the laser emission to the return from the side object, and synchronously measures the laser pulse value to generate data. After the scanning is completed, the scanned data position set can be exported, and the data in the height dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com