A fully automatic keyboard assembly line

An assembly line, fully automatic technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of high production cost, large assembly line structure, and difficulty in improving assembly efficiency, so as to reduce production cost, reduce overall volume, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

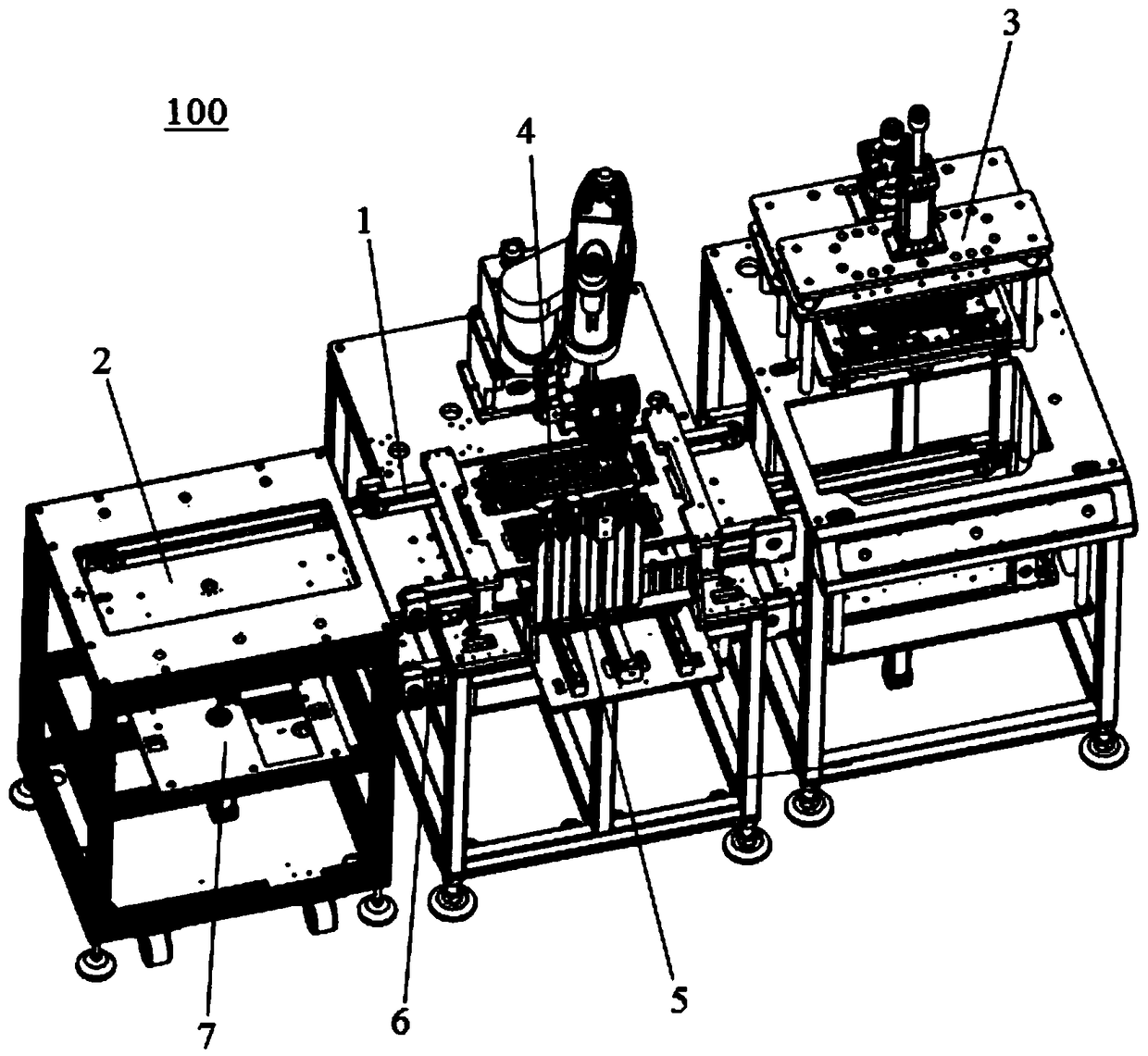

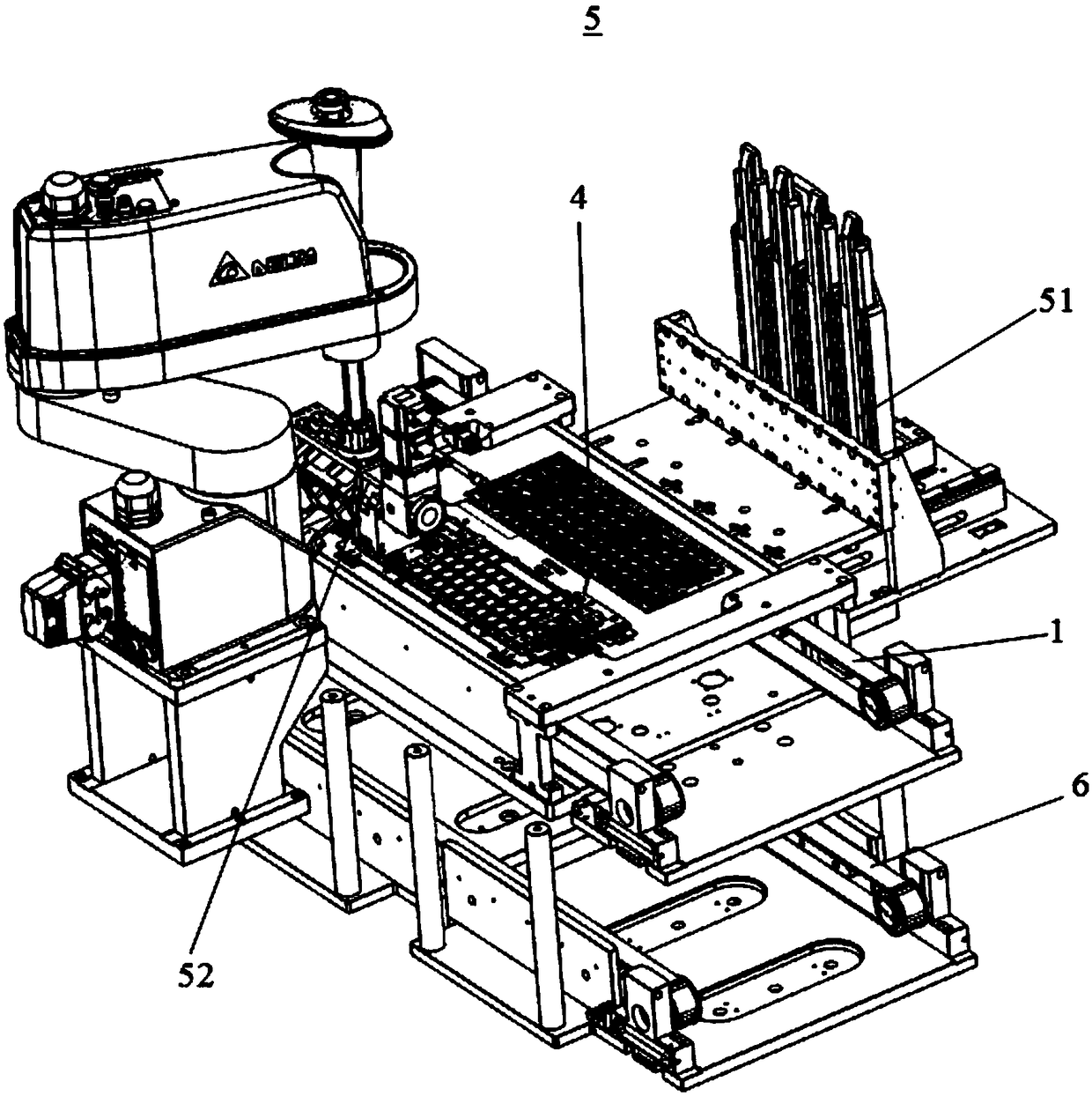

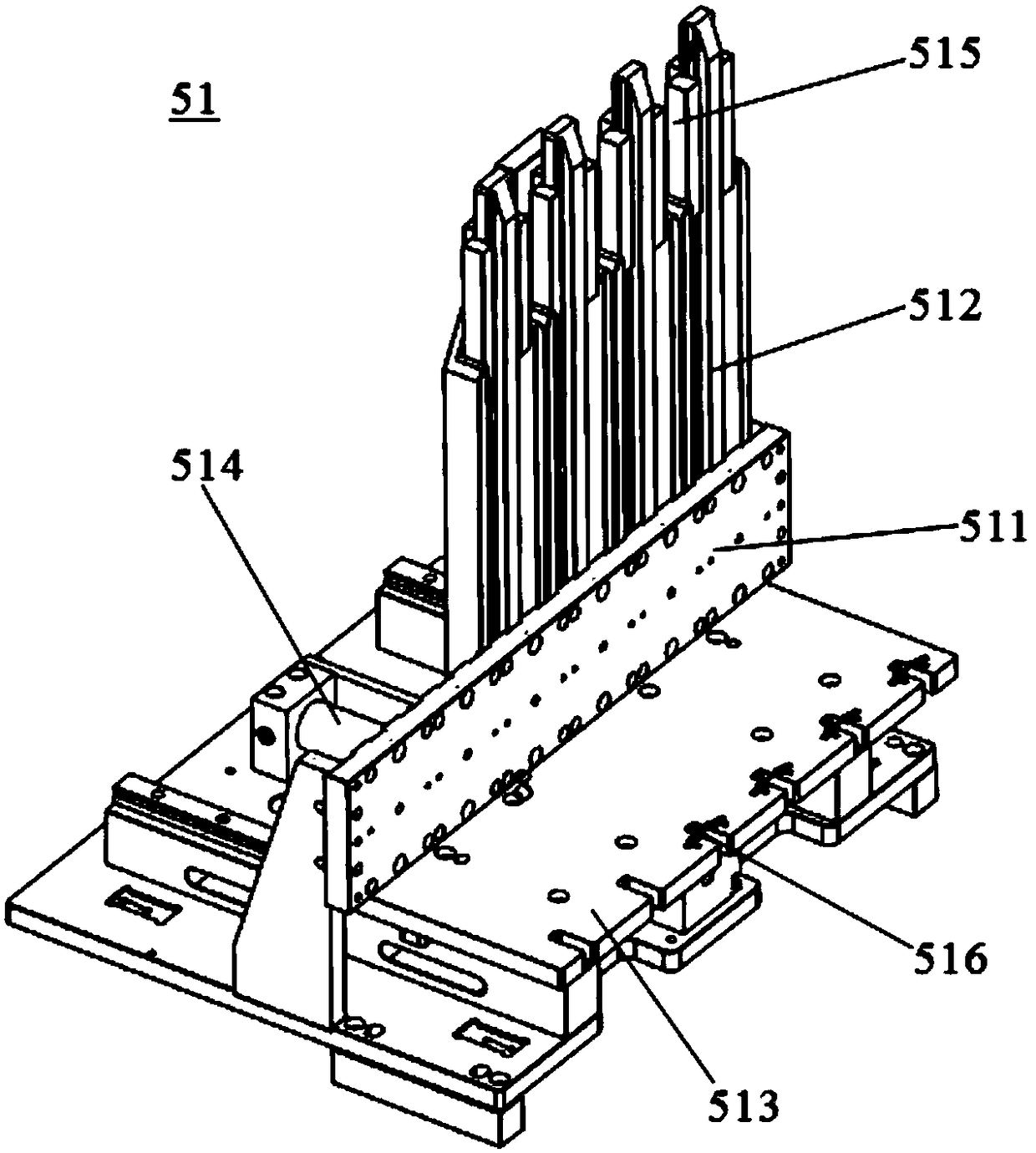

[0036] Please refer to Figure 1-Figure 16 , the present embodiment is a fully automatic keyboard assembly line 100, which includes a first conveying line 1 for conveying keyboard substrates and keycap fixtures, a keyboard substrate feeding station 2 located at the head end of the first conveying line 1, and a keyboard substrate loading station 2 along the first conveying line. 1 Integrated assembly equipment for several balance bars and special keycaps 5, substrate tooling 4 moving on the first conveying line 1, common key assembly equipment arranged along the first conveying line 1, and the second substrate tooling 4 for recycling Two conveying lines 6 and a transition mechanism connecting the first conveying line 1 and the second conveying line 6 .

[0037] In one embodiment, the first conveying line 1 includes two substrate conveying lines and keycap fixture conveying lines arranged in parallel, and the keycap fixture conveying line is directly connected to the conveying l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com