A kind of preparation method and application of gel electrolyte

A technology of gel electrolyte and electrolyte, which is applied in the field of preparation of in-situ gel electrolyte, can solve problems such as increased energy consumption and cost, complicated preparation methods, and harsh gelation conditions, and achieves improved cycle life, wide application, and reduced The effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Put the metal lithium flakes in the pre-set solution, the ratio of the two is 1g:1ml, shake it under a magnetic stirrer for 2 days, and the treatment temperature is 25°C, to obtain the metal lithium flakes with an initiating amine compound protective layer on the surface ( figure 1 ). Wherein, the preset solution that can be used for the reaction is a dimethyl carbonate solution containing the diamine ethylenediamine, wherein the proportion of ethylenediamine is 2%.

[0034]2) Add the above-mentioned metal lithium sheet with an initiating amine compound protective layer on the surface to the electrolyte solution, the ratio of the two is 10g:1ml, after standing for 5 days, the electrolyte solution is gelled in situ, and an in situ gel electrolyte is obtained . Wherein, the electrolytic solution is tetraethylene glycol dimethyl ether solution containing 1M LiTFSI.

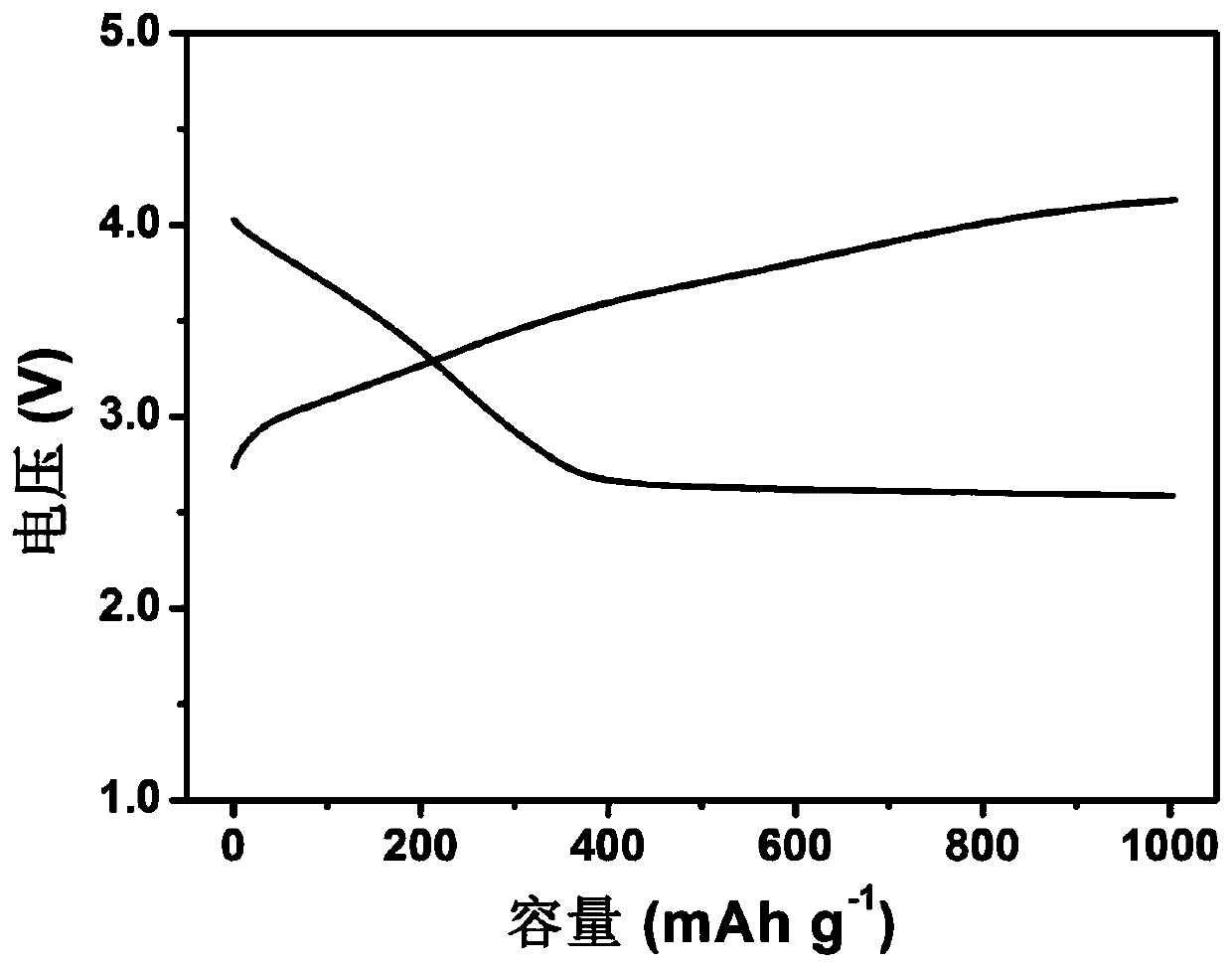

[0035] Among them, the positive electrode material manganese dioxide (MnO 2 , mass percent 50%), con...

Embodiment 2

[0040] 1) Put metal lithium-sodium alloy foil in the preset solution, the ratio of the two is 2g:1ml, and let stand. The treatment time is 10 minutes, and the treatment temperature is 20° C. to obtain a metal lithium sodium alloy foil with an initiating amino compound protective layer on the surface. Wherein, the mass ratio of lithium in the metal lithium-sodium alloy foil is 20%, and the preset solution that can be used for the reaction is diamine butylenediamine.

[0041] 2) Assemble the sodium-oxygen battery with the above-mentioned metal lithium-sodium alloy foil having an initiating amine compound protective layer on the surface and an electrolyte. The ratio of the two is 8g:1ml. After the battery has been left standing for 7 days, the electrolyte is gelled in situ to obtain an in situ gel electrolyte. Among them, the electrolyte contains 0.5M NaClO 4 solution of ethylene glycol dimethyl ether. The sodium oxygen battery is a CR2025 button battery.

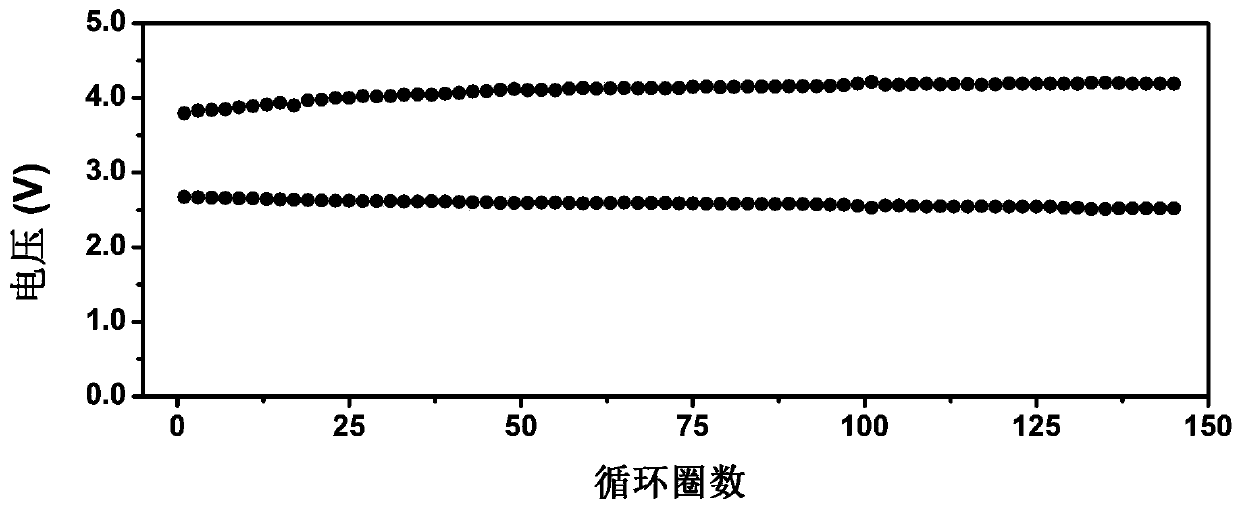

[0042] The obtaine...

Embodiment 3

[0045] 1) Put metal lithium-potassium alloy strips in the preset solution, the ratio of the two is 3g:1ml, and vibrate. The treatment time is 0.5 day, and the treatment temperature is 30° C. to obtain metal lithium potassium alloy strips with an initiating amino compound protective layer on the surface. Wherein, the mass ratio of lithium in the metallic lithium-potassium alloy strip is 70%, and the preset solution that can be used for the reaction is an acetonitrile solution containing the monoamine diethylamine, wherein the proportion of diethylamine is 0.5%.

[0046] 2) Assemble the lithium-potassium metal alloy strip with the protective layer of the initiating amine compound on the surface and the electrolyte solution to the metal potassium ion battery. The ratio of the two is 5g:1ml. After the battery is left standing for 4 days, the electrolyte solution is gelled in situ, and an in situ gel electrolyte is obtained. Among them, the electrolyte contains 0.1M KPF 6 solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com