A kind of cable vulcanization method

A technology for cables and cable bundles, which is applied in the field of cable vulcanization, and can solve problems such as loose outlets and poor sealing of cable connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

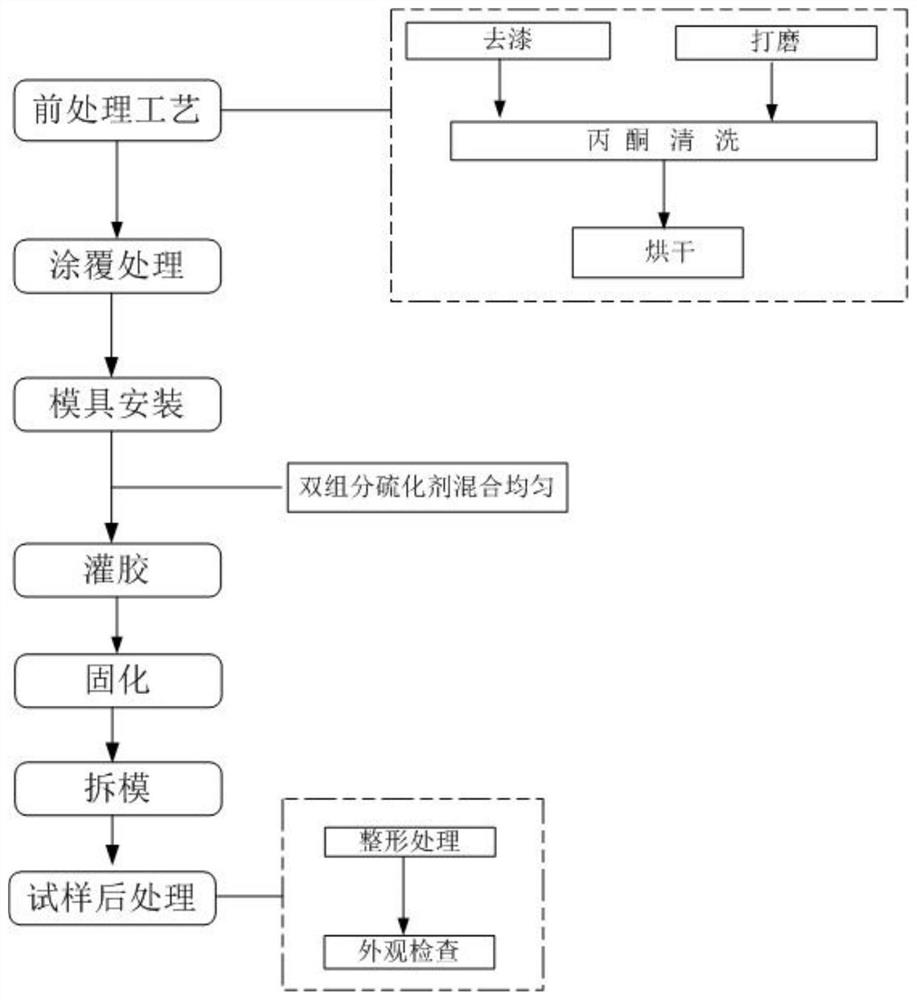

[0073] (1) Pretreatment process: before vulcanization, clean the parts to be vulcanized.

[0074] a. First use a special tool to remove the paint on the outer surface of the outlet of the cable connector; then use a brush to clean the polished powder, requiring no powder and excess residue; then clean the surface to be vulcanized with acetone, after cleaning Blow for two minutes with a heat gun set at 80°C.

[0075] b. First use sandpaper to polish the plastic protective cover on the surface of the cable bundle, so that the surface to be vulcanized has a certain roughness, and the plastic protective cover on the surface of the cable bundle is not damaged; then use a brush to clean the polished powder. There is no powder and excess residue; then clean the surface to be vulcanized with acetone, and after cleaning, set the heat gun at 80°C to blow for two minutes.

[0076] (2) Coating treatment

[0077] Dip 401 glue with a paintbrush and evenly coat the surface to be vulcanized...

Embodiment 2

[0091] (1) Pretreatment process: before vulcanization, clean the parts to be vulcanized.

[0092] a. First use a special tool to remove the paint on the outer surface of the outlet of the cable connector; then use a brush to clean the polished powder, requiring no powder and excess residue; then clean the surface to be vulcanized with acetone, after cleaning Blow for two minutes with a heat gun set at 80°C.

[0093] b. First use sandpaper to polish the plastic protective cover on the surface of the cable bundle, so that the surface to be vulcanized has a certain roughness, and the plastic protective cover on the surface of the cable bundle is not damaged; then use a brush to clean the polished powder. There is no powder and excess residue; then clean the surface to be vulcanized with acetone, and after cleaning, set the heat gun at 80°C to blow for two minutes.

[0094] (2) Coating treatment

[0095] Dip RM-1 glue with a paintbrush and evenly coat the surface to be vulcanize...

Embodiment 3

[0109] (1) Pretreatment process: before vulcanization, clean the parts to be vulcanized.

[0110] a. First use a special tool to remove the paint on the outer surface of the outlet of the cable connector; then use a brush to clean the polished powder, requiring no powder and excess residue; then clean the surface to be vulcanized with acetone, after cleaning Blow for two minutes with a heat gun set at 80°C.

[0111] b. First use sandpaper to polish the plastic protective cover on the surface of the cable bundle, so that the surface to be vulcanized has a certain roughness, and the plastic protective cover on the surface of the cable bundle is not damaged; then use a brush to clean the polished powder. There is no powder and excess residue; then clean the surface to be vulcanized with acetone, and after cleaning, set the heat gun at 80°C to blow for two minutes.

[0112] (2) Coating treatment

[0113] Use a paintbrush to dip in Chemlock 218 adhesive and apply evenly on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com