Stamping device of aluminum profile production line

A stamping device and production line technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of inconvenient mold installation and difficulty in ensuring the synchronization of stamping actions, etc., and achieve simple structure, stable and reliable driving force, and synchronous actions high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Example: see Figure 1-8 Shown:

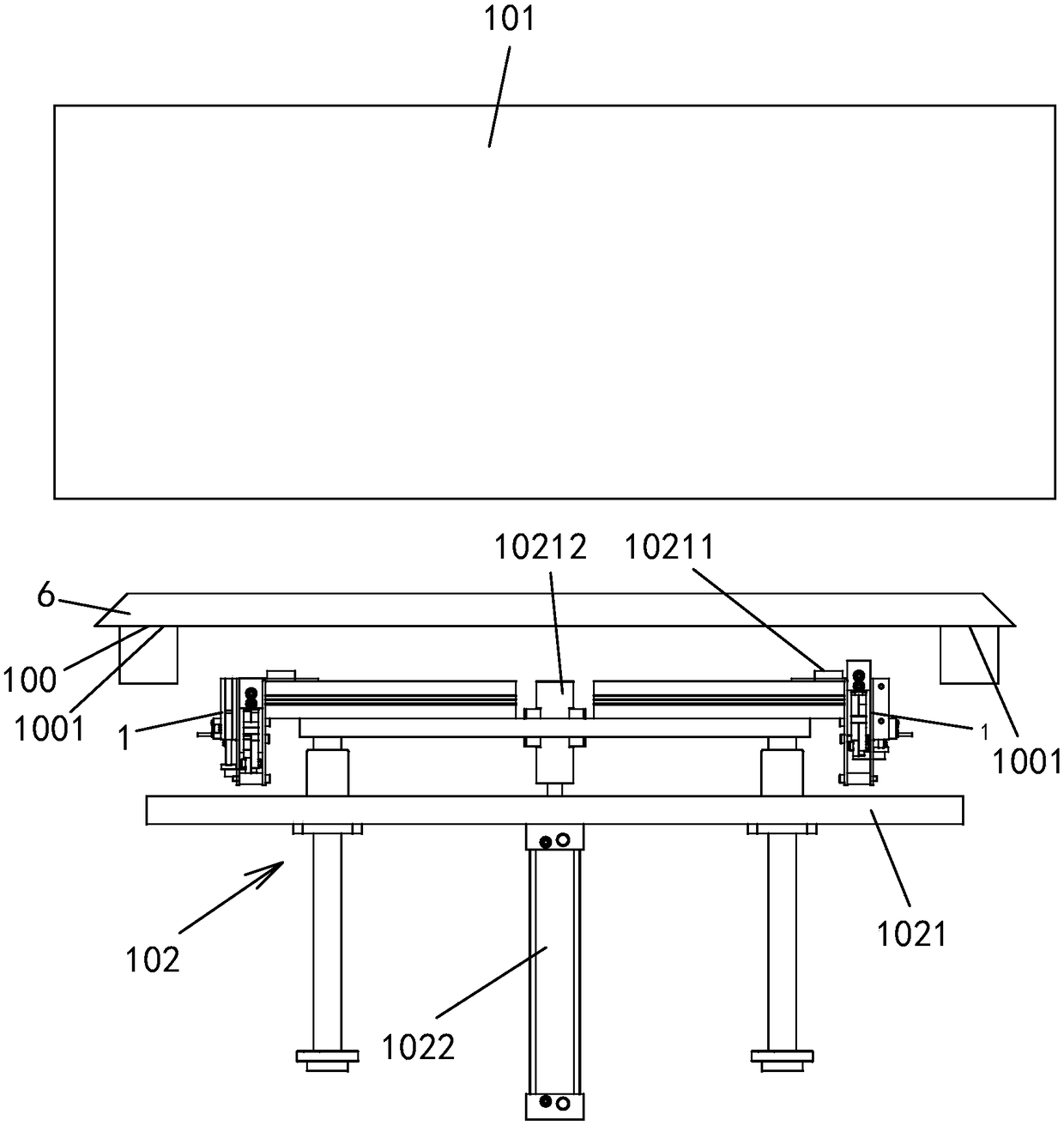

[0026] A stamping device for aluminum profile production line, see figure 1 As shown, a profile conveying surface 100 is included. The profile conveying surface 100 is composed of two conveying belt surfaces 1001 arranged side by side at a distance; a horizontal stamping unit 101 is arranged above the profile conveying surface 100, and the two conveying belts A profile lifting assembly 102 is provided between the surfaces 1001 corresponding to the horizontal punching unit 101.

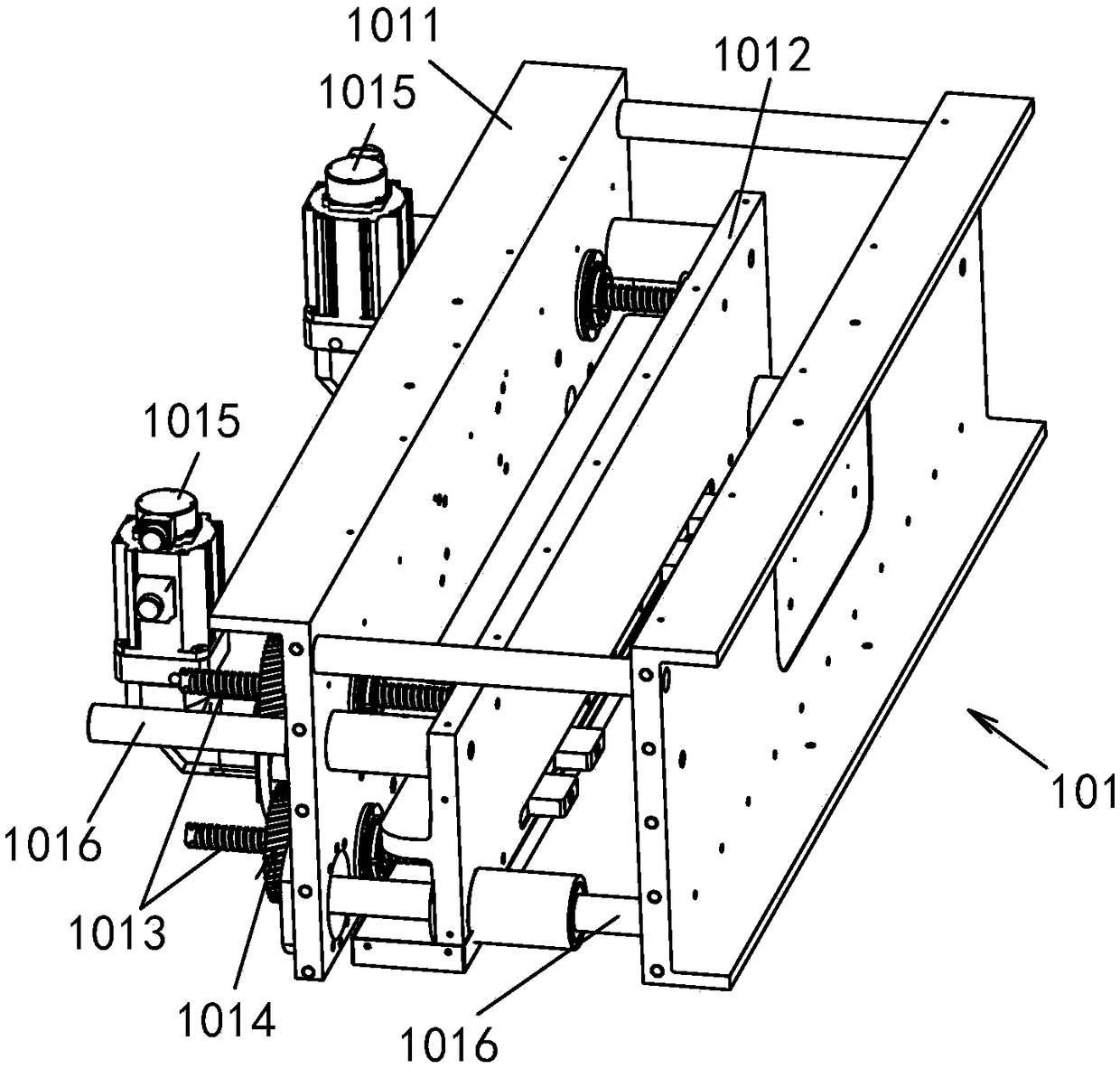

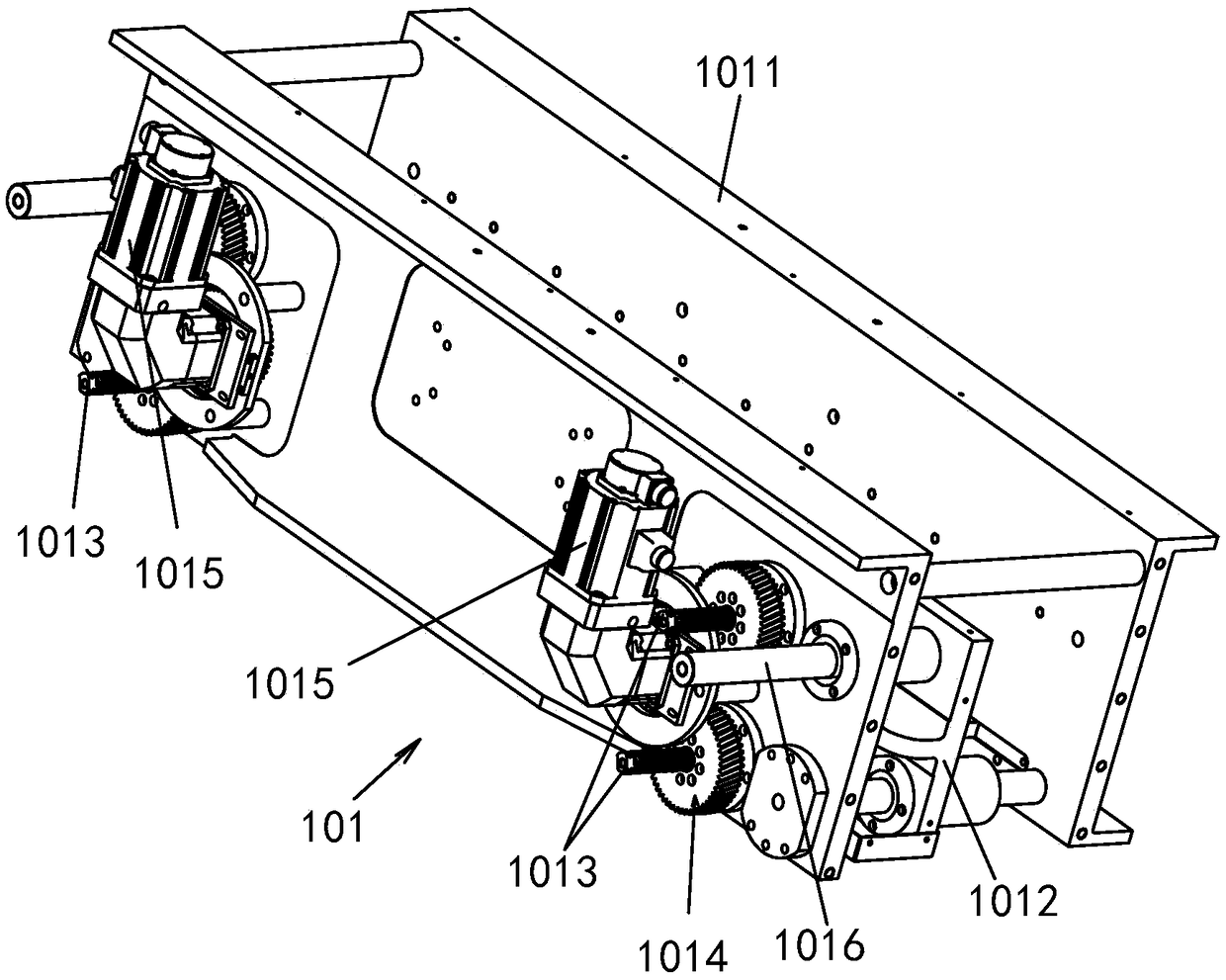

[0027] See figure 2 with image 3 As shown, the horizontal stamping unit 101 includes a fixed frame 1011, an upper mold pressing plate 1012, an upper mold driving device, an upper mold, and a lower mold; the upper mold pressing plate 1012 is connected along the two conveyor belt surfaces 1001 The line direction is set, the surface of the upper molded plate 1012 is perpendicular to the horizontal plane, and the upper molded plate 1012 is guided and connected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com