Prefabricated beam steam curing shed and construction method thereof

A prefabricated beam and steam technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of high cost, inconvenient production and maintenance, and achieve a small storage space, saving labor costs and labor intensity, and low production and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

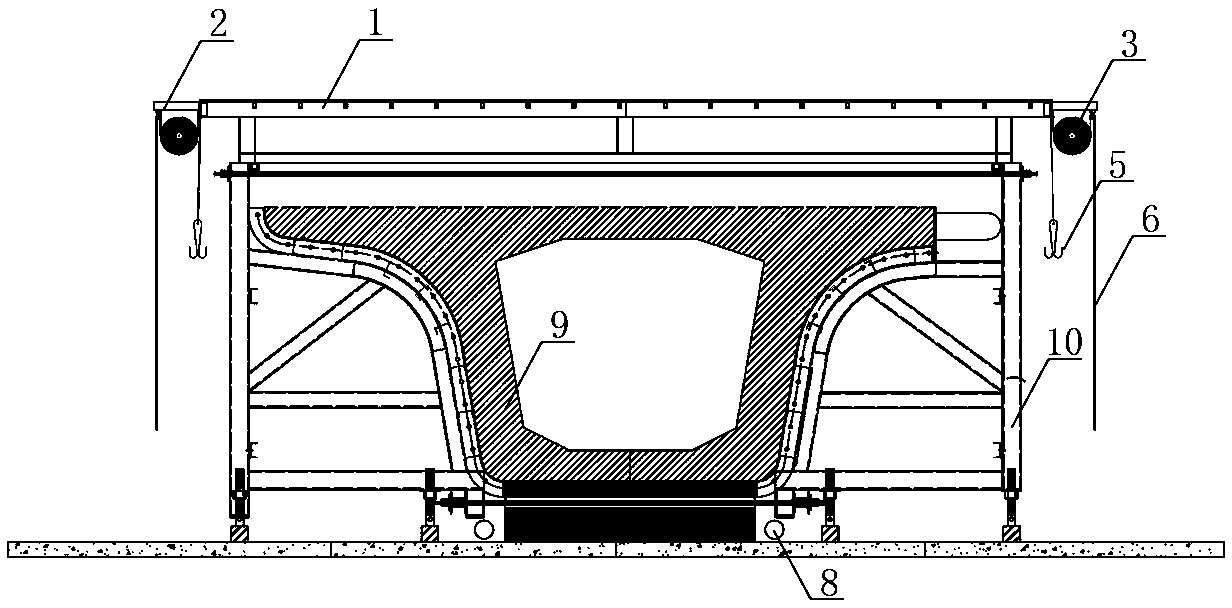

[0048] Examples see figure 1 As shown, this prefabricated beam steam health shed includes a closed shed body and a steam health care device 8 arranged in the shed body; the closed shed body includes a top frame 1 arranged above the prefabricated beam 9 and a The flexible material layer 3 on four sides and the top surface. The top frame 1 is adapted to the size of the prefabricated beams. The steam curing device includes a steam curing pipeline placed under the prefabricated beam.

[0049] see figure 1 As shown, during storage, the flexible material layer 3 on the four sides of the prefabricated beam is rolled upwards in a cylindrical shape, and is correspondingly connected around the top frame 1 .

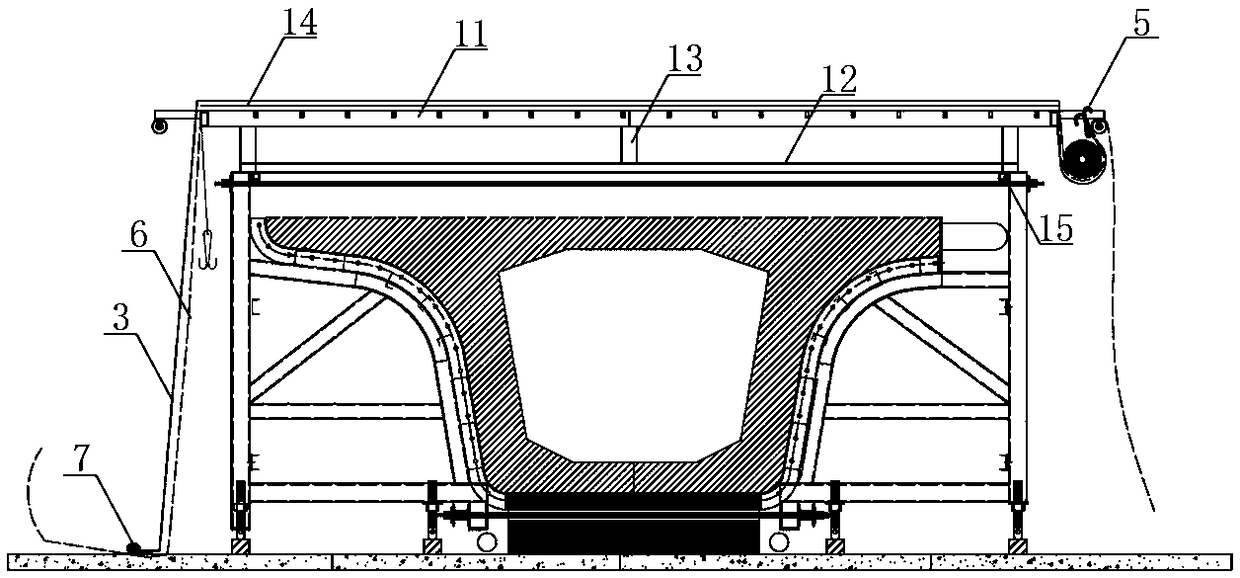

[0050] see figure 2 As shown, when opened, the flexible material layers 3 on the four sides of the prefabricated beam are opened downwards in a sheet shape, and are vertically arranged on the working surface.

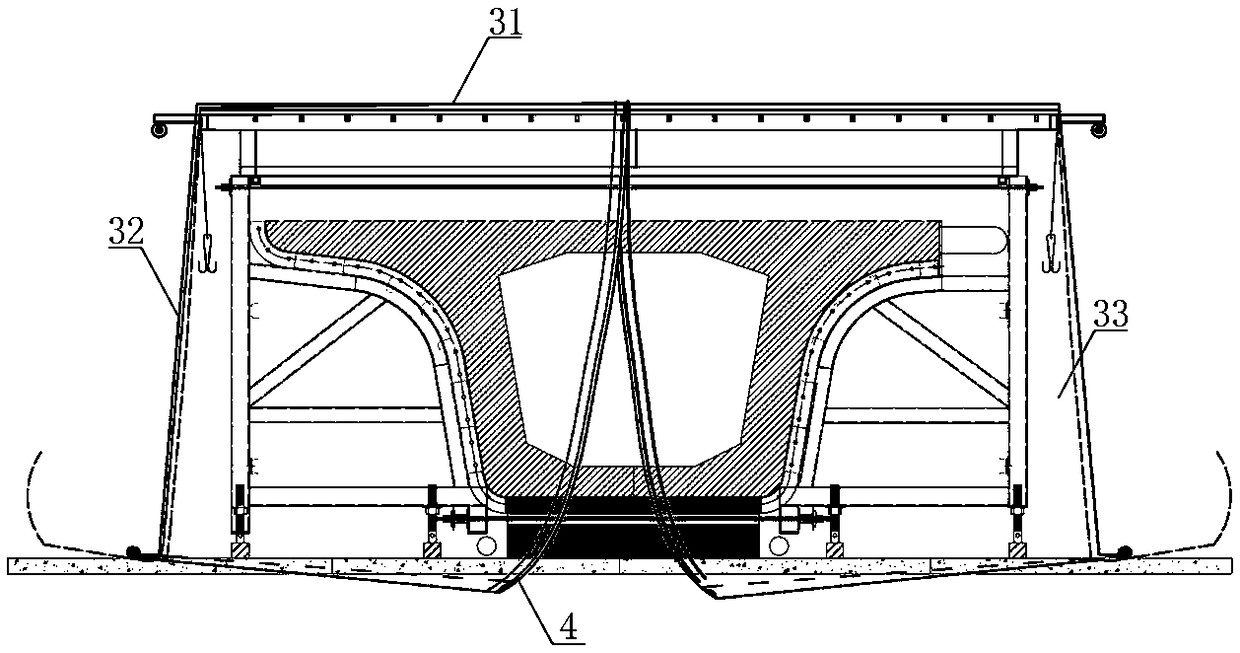

[0051] see Figure 4 As shown, the top frame 1 includes a group of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com