Sewing method capable of fast overlock

A seaming and sewing technology, which is applied in the direction of sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of sewing position deviation, cloth and cloth position deviation, and seaming method can not meet the needs of use, so as to prevent dust or Effects of removing foreign matter, improving fit, and facilitating seaming and wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

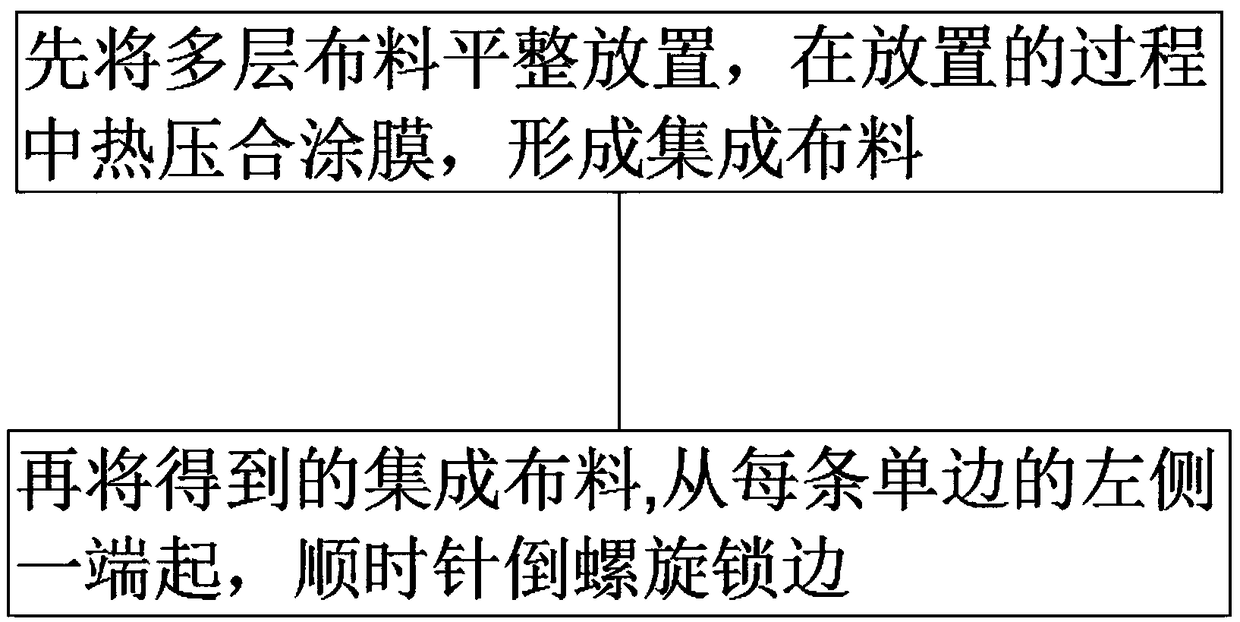

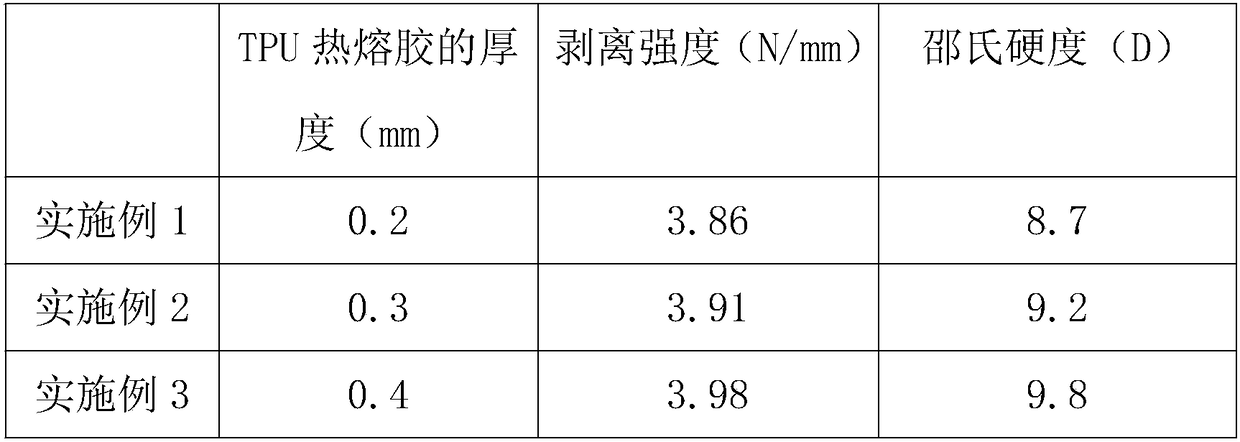

[0028] (1) First place the multi-layer fabric that needs to be sewn and seamed flat. During the placement process, the edges of the fabric are bonded by hot-pressing the coating film. The coating film is TPU hot-melt adhesive, TPU hot-melt adhesive coating Coated on the edge of the fabric 8mm, and the coating width is 1.2cm, the thickness of the TPU hot melt adhesive is 0.2mm, and the thermal compression coating includes the following steps:

[0029] (1.1), first place the bottom fabric flat on the workbench, then apply TPU hot melt adhesive on the edge of the bottom fabric, and finally, place the fabric to be glued on top of the bottom fabric, and repeat the coating. Complete the coating of multi-layer fabrics;

[0030] (1.2), thermally pressing the coated multi-layer cloth to form an integrated cloth;

[0031] (2) Then start from the left end of each single side of the integrated fabric obtained in step (1), and spirally lock the edge clockwise. The spiral edge lock include...

Embodiment 2

[0037] (1) First place the multi-layer fabric that needs to be sewn and seamed flat. During the placement process, the edges of the fabric are bonded by hot-pressing the coating film. The coating film is TPU hot-melt adhesive, TPU hot-melt adhesive coating Coated on the edge of the fabric 8mm, and the coating width is 1.2cm, the thickness of the TPU hot melt adhesive is 0.3mm, and the thermal compression coating includes the following steps:

[0038] (1.1), first place the bottom fabric flat on the workbench, then apply TPU hot melt adhesive on the edge of the bottom fabric, and finally, place the fabric to be glued on top of the bottom fabric, and repeat the coating. Complete the coating of multi-layer fabrics;

[0039] (1.2), thermally pressing the coated multi-layer cloth to form an integrated cloth;

[0040] (2) Then start from the left end of each single side of the integrated fabric obtained in step (1), and spirally lock the edge clockwise. The spiral edge lock include...

Embodiment 3

[0046] (1) First place the multi-layer fabric that needs to be sewn and seamed flat. During the placement process, the edges of the fabric are bonded by hot-pressing the coating film. The coating film is TPU hot-melt adhesive, TPU hot-melt adhesive coating Coated on the edge of the fabric 8mm, and the coating width is 1.2cm, the thickness of the TPU hot melt adhesive is 0.4mm, and the thermal compression coating includes the following steps:

[0047] (1.1), first place the bottom fabric flat on the workbench, then apply TPU hot melt adhesive on the edge of the bottom fabric, and finally, place the fabric to be glued on top of the bottom fabric, and repeat the coating. Complete the coating of multi-layer fabrics;

[0048] (1.2), thermally pressing the coated multi-layer cloth to form an integrated cloth;

[0049] (2) Then start from the left end of each single side of the integrated fabric obtained in step (1), and spirally lock the edge clockwise. The spiral edge lock include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com