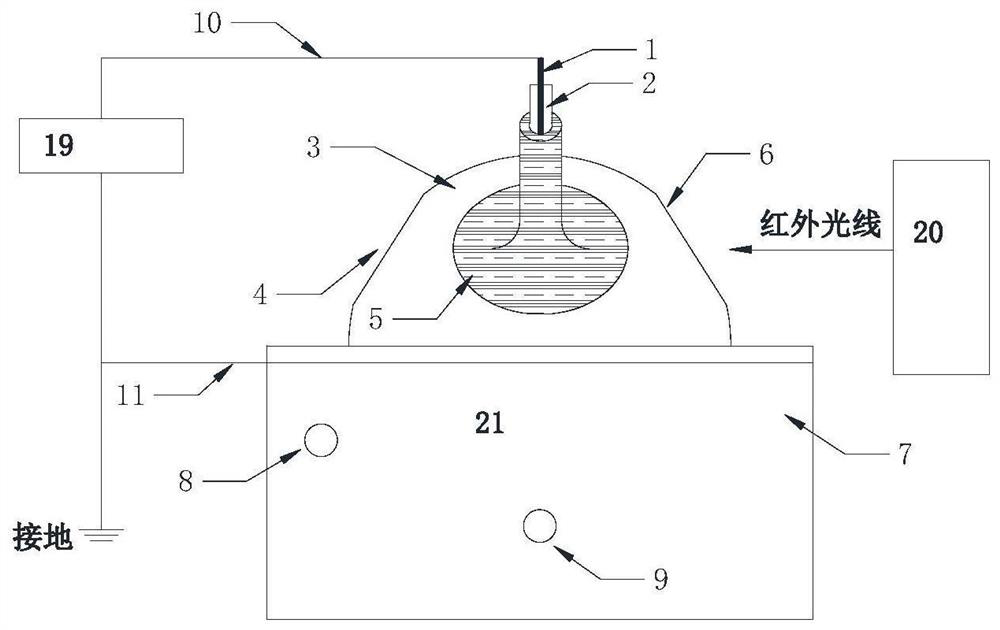

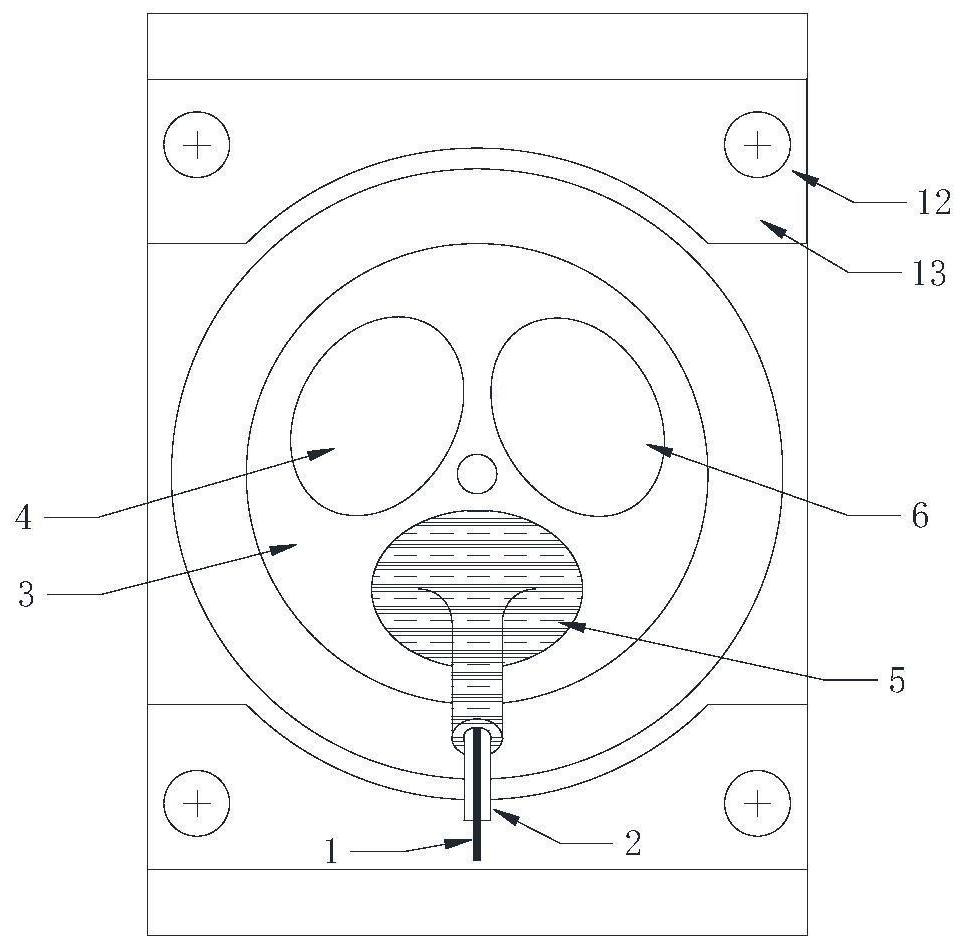

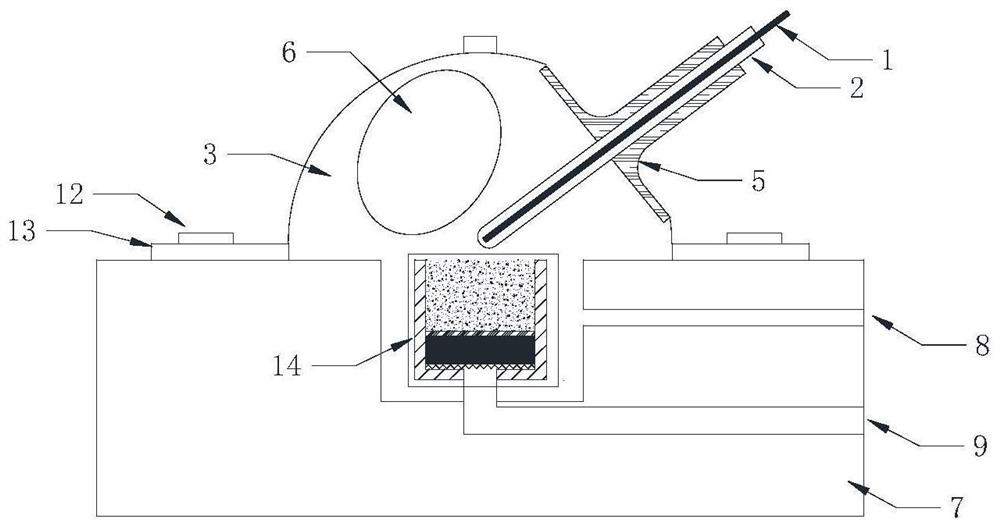

A device and method for realizing dielectric barrier discharge in an in-situ cell of an in-situ infrared analysis device

A technology of dielectric barrier discharge and analysis device, applied in the field of analysis and detection, can solve problems such as obstacles to mechanism research, little research on intermediate substances, and unclear what substances are formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In this example, the electrode Ⅰ and electrode Ⅱ are made of stainless steel, the insulating tube is made of quartz glass, the electrode Ⅱ is a square plate with no holes, and two high-temperature-resistant circular aluminum oxide gaskets with a thickness of 0.5 mm are placed under the electrode Ⅱ. Thus, the thickness of the sample is 2 mm, and the distance between electrode I and electrode II is 2.5 mm.

[0059] In actual use, the steps are as follows:

[0060] (1) The electrode I1 and the electrode II16 are respectively connected to the high-voltage power supply through the wire I10 and the wire II11, and the wire II11 is grounded at the same time.

[0061] (2) The high-voltage output from the high-voltage power supply is loaded on the electrode I1 and the electrode II16, so that the discharge space above the sample between the electrode I1 and the electrode II16 forms an electric field, and the gas in the discharge space is ionized to generate electrons and ions . ...

Embodiment 2

[0066] Putting Al in the in situ pool 2 o 3 Catalyst, feed CO 2 After adsorption, the catalyst is discharged and regenerated. The purpose is to observe the Al in the discharge plasma field 2 o 3 Changes on the surface of the catalyst, thus inferring that the Al 2 o 3 Reaction mechanism of catalyst regeneration.

[0067] When using it specifically, the steps are as follows:

[0068] (1) Al 2 o 3 The catalyst powder is installed in the sample cell, the surface of the sample is smeared flat, and the gas temperature in the in-situ cell is controlled at 25°C (controlled by a thermostat); the electrode I10 and the electrode II16 are connected to the high-voltage power supply through the metal stainless steel wire I21 and the metal stainless steel wire II22 respectively. Connection, the metal stainless steel wire Ⅱ22 is grounded at the same time.

[0069] (2) In the in-situ cell, the total flow rate of gas is 50mL / min helium for 10min, and the background spectrum is collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com