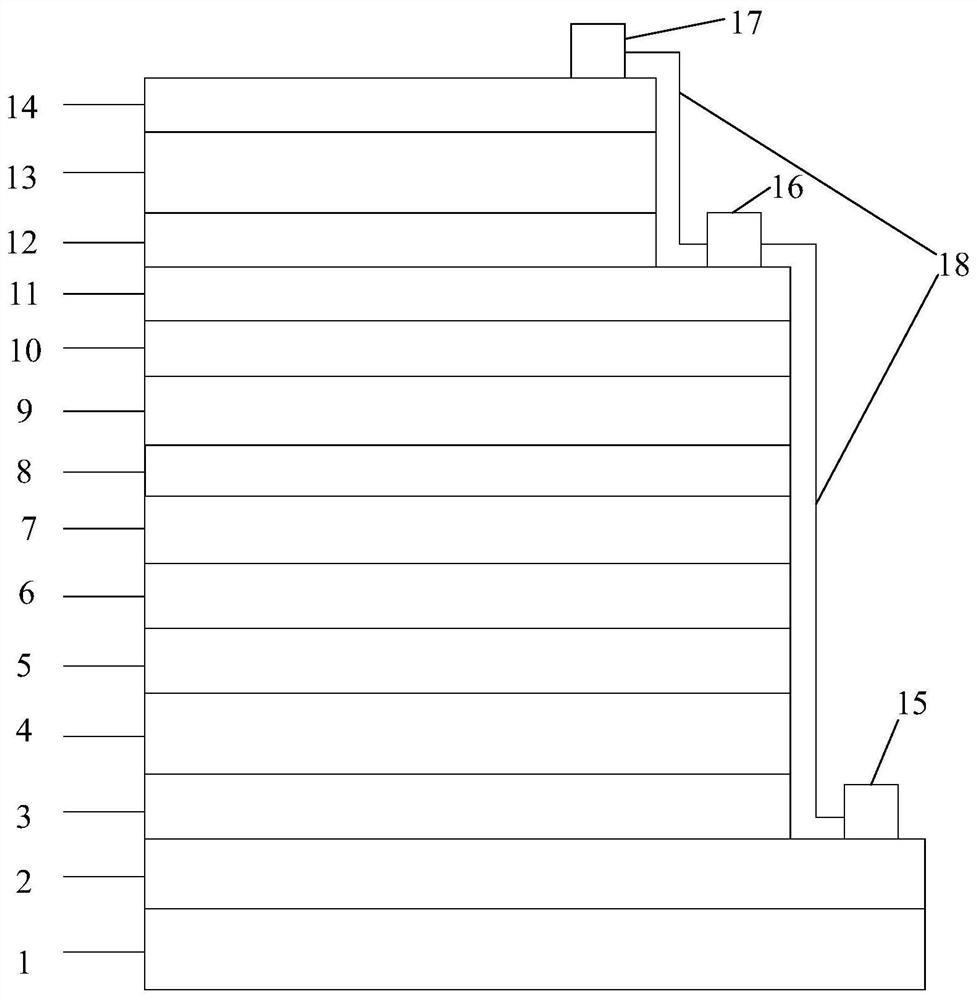

A short-wave/medium-wave/long-wave three-band infrared detector and its preparation method

An infrared detector, three-band technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as the gap between InAsSb photoelectric infrared detectors, suppress tunneling dark current, reduce detection limits, The effect of high detection rate and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

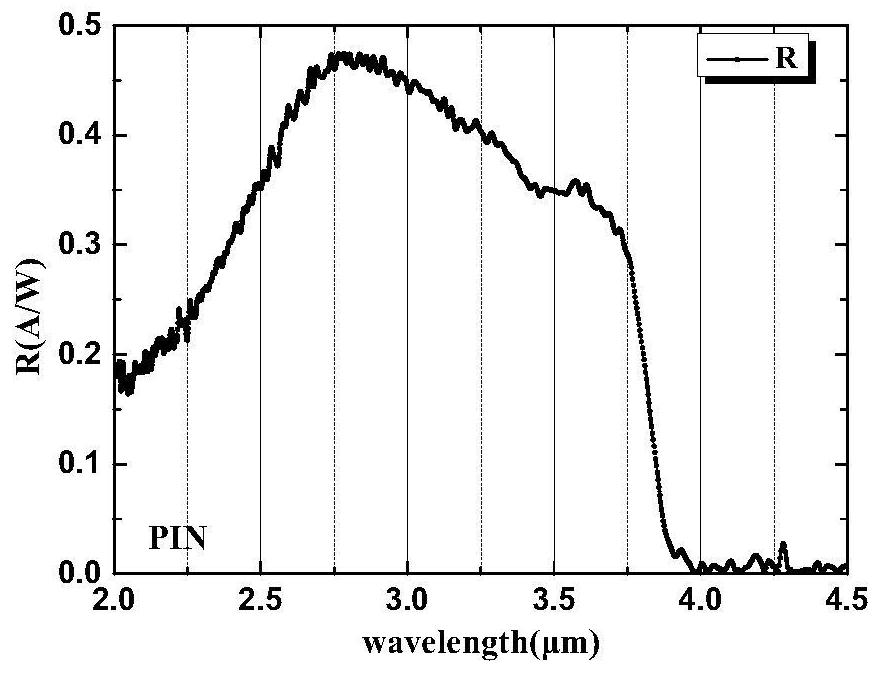

Embodiment 1

[0048]In the embodiment of the present invention, the degassed N-type GaSb(001) substrate is transferred into the growth chamber to heat up and remove the oxide layer. After the substrate temperature exceeds 370°C, the Sb protection beam is introduced, and the size of the Sb protection beam is at 10 -6 Torr level, real-time monitoring by RHEED, add 30°C to 620°C on the basis of the temperature 590°C when the deoxidation point appears on the substrate surface, and remove the oxide layer for 25 minutes.

[0049] In the embodiment of the present invention, the n-type doped GaSb buffer layer 2 is grown on the GaSb substrate 1 with a thickness of 1.1 μm. Among them, the Te doping concentration in the GaSb buffer layer is close to 2×10 18 cm -3 .

[0050] In the embodiment of the present invention, the n-type InAs / GaSb superlattice contact layer 3 is grown on the n-type doped GaSb buffer layer 2 with a thickness of 0.5 μm. This layer is composed of alternately grown GaSb barrier...

Embodiment 2

[0068] In the embodiment of the present invention, the degassed N-type GaSb(001) substrate is transferred into the growth chamber to heat up and remove the oxide layer. After the substrate temperature exceeds 370°C, the Sb protection beam is introduced, and the size of the Sb protection beam is at 10 -6 The Torr level is monitored in real time by REED. On the basis of the temperature of 600°C when the deoxidation point appears on the substrate surface, add 30°C, that is, 630°C, and deoxidize for 20 minutes.

[0069] In the embodiment of the present invention, the n-type doped GaSb buffer layer 2 is grown on the GaSb substrate 1 with a thickness of 0.92 μm. Among them, the Te doping concentration in the GaSb buffer layer is close to 2×10 18 cm -3 .

[0070] In the embodiment of the present invention, the n-type InAs / GaSb superlattice contact layer 3 is grown on the n-type doped GaSb buffer layer 2, and its thickness is 0.53 μm. This layer is composed of alternately grown Ga...

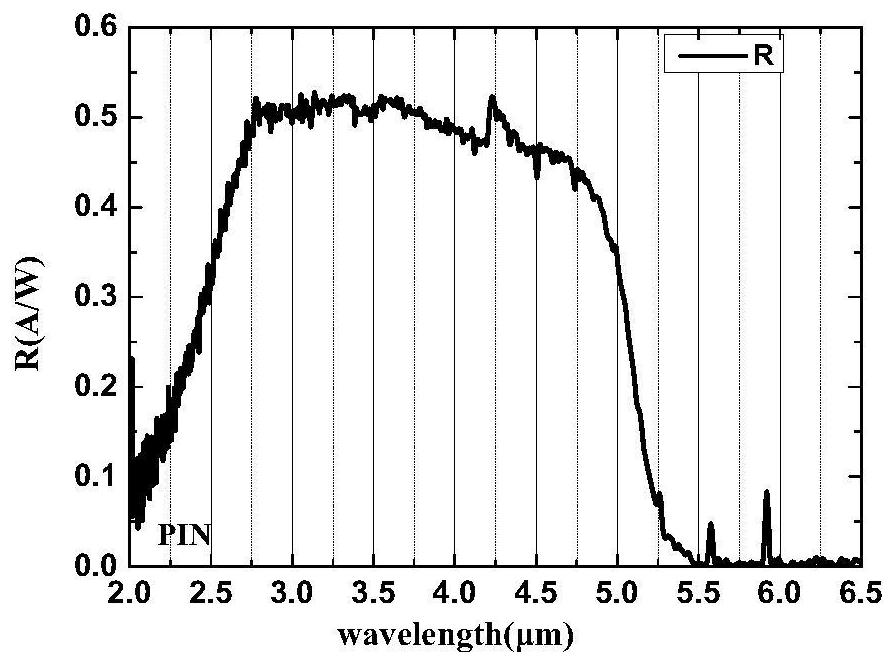

Embodiment 3

[0085] In the embodiment of the present invention, the degassed N-type GaSb(001) substrate is transferred into the growth chamber to heat up and remove the oxide layer. After the substrate temperature exceeds 370°C, the Sb protection beam is introduced, and the size of the Sb protection beam is at 10 -6 The Torr level is monitored in real time by REED. On the basis of the temperature of 600°C when the deoxidation point appears on the substrate surface, add 30°C, that is, 630°C, and deoxidize for 22 minutes.

[0086] In the embodiment of the present invention, the n-type doped GaSb buffer layer 2 is grown on the GaSb substrate 1 with a thickness of 0.88 μm. Among them, the Te doping concentration in the GaSb buffer layer is close to 2×10 18 cm -3 .

[0087] In the embodiment of the present invention, the n-type InAs / GaSb superlattice contact layer 3 is grown on the n-type doped GaSb buffer layer 2 with a thickness of 0.5 μm. This layer consists of alternately grown GaSb bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com