A kind of preparation method of three-color infrared detector

A technology of infrared detector and infrared absorbing layer, which is applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of not showing high performance, achieve the suppression of tunneling dark current, improve performance, and improve The effect of detecting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

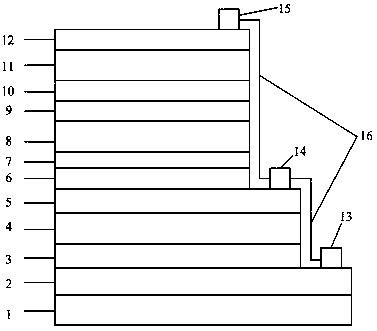

[0040] In the embodiment of the present invention, the degassed N-type GaSb (001) substrate is transferred into the growth chamber to remove the oxide layer by raising the temperature. After the substrate temperature exceeds 370 ° C, the Sb protection beam is introduced, and the size of the Sb protection beam is at 10 -6 Torr level, real-time monitoring by REED, 30°C is added to the temperature of 600°C when the deoxidation point appears on the substrate surface, that is, 630°C, and deoxidation is performed for 22 minutes.

[0041] In the embodiment of the present invention, the p-type doped GaSb buffer layer 2 is grown on the GaSb substrate 1 with a thickness of 1.1 μm. Among them, the Be doping concentration in the GaSb buffer layer is close to 2×10 18 cm -3 .

[0042] In the embodiment of the present invention, the p-type InAs / InAsSb superlattice contact layer 3 is grown on the p-type doped GaSb buffer layer 2 with a thickness of 0.677 μm. The layer consists of altern...

Embodiment 2

[0055] In the embodiment of the present invention, the degassed N-type GaSb (001) substrate is transferred into the growth chamber to remove the oxide layer by raising the temperature. After the substrate temperature exceeds 370 ° C, the Sb protection beam is introduced, and the size of the Sb protection beam is at 10 -6 Torr level, real-time monitoring by REED, on the basis of the temperature 600°C when the deoxidation point appears on the substrate surface, add 30°C, that is, 630°C, and deoxidize for 26 minutes.

[0056] In the embodiment of the present invention, the p-type doped GaSb buffer layer 2 is grown on the GaSb substrate 1 with a thickness of 0.88 μm. Among them, the Be doping concentration in the GaSb buffer layer is close to 2×10 18 cm -3 .

[0057] In the embodiment of the present invention, the p-type InAs / InAsSb superlattice contact layer 3 is grown on the p-type doped GaSb buffer layer 2 with a thickness of 0.677 μm. The layer consists of alternately gr...

Embodiment 3

[0070] In the embodiment of the present invention, the degassed N-type GaSb (001) substrate is transferred into the growth chamber to remove the oxide layer by raising the temperature. After the substrate temperature exceeds 370 ° C, the Sb protection beam is introduced, and the size of the Sb protection beam is at 10 -6 Torr level, real-time monitoring by REED, 30°C is added to the temperature of 600°C when the deoxidation point appears on the substrate surface, that is, 630°C, and deoxidation is carried out for 18 minutes.

[0071] In the embodiment of the present invention, the p-type doped GaSb buffer layer 2 is grown on the GaSb substrate 1 with a thickness of 1 μm. Among them, the Be doping concentration in the GaSb buffer layer is close to 2×10 18 cm -3 .

[0072] In the embodiment of the present invention, the p-type InAs / InAsSb superlattice contact layer 3 is grown on the p-type doped GaSb buffer layer 2 with a thickness of 0.677 μm. The layer consists of altern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com