Mechanical shrimp peeling tool

A mechanical shrimp peeling technology, which is applied in shrimp/lobster processing, crustacean processing, slaughtering, etc., can solve the problems of endless cutting, complex structure, high manufacturing and installation requirements, etc., to achieve easy operation, improve work efficiency, The effect of high shell removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

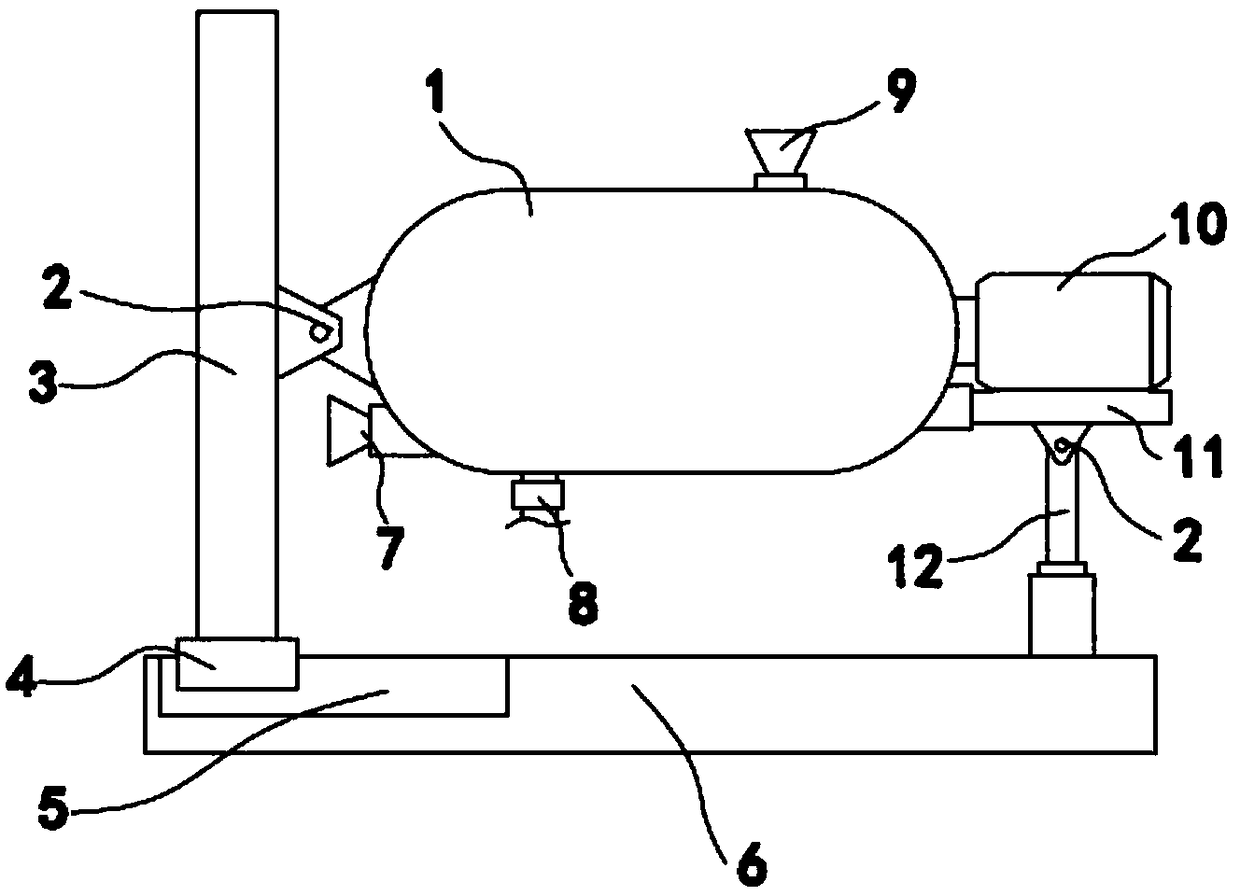

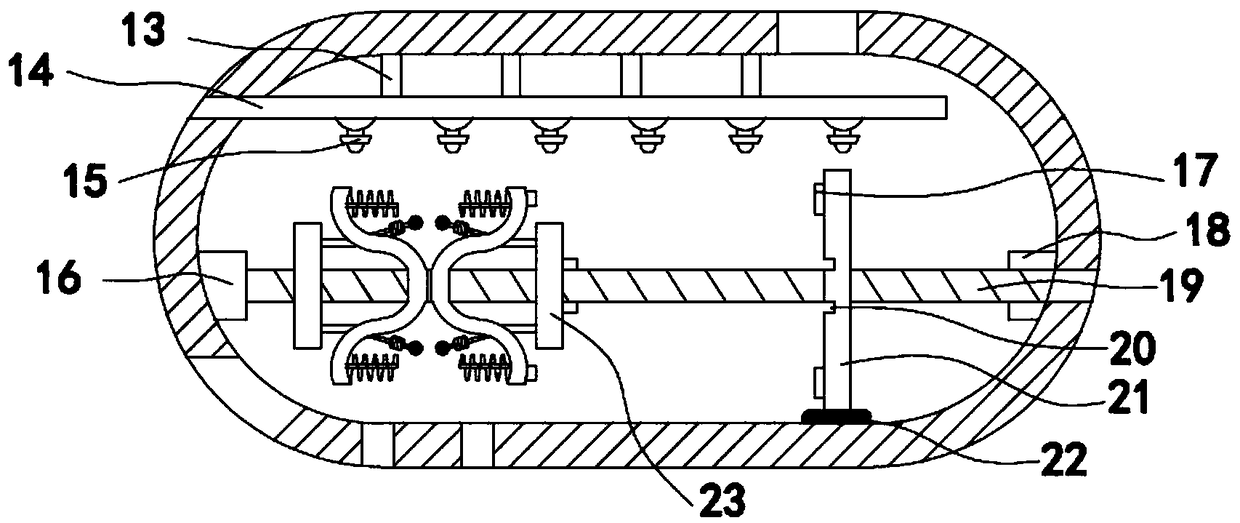

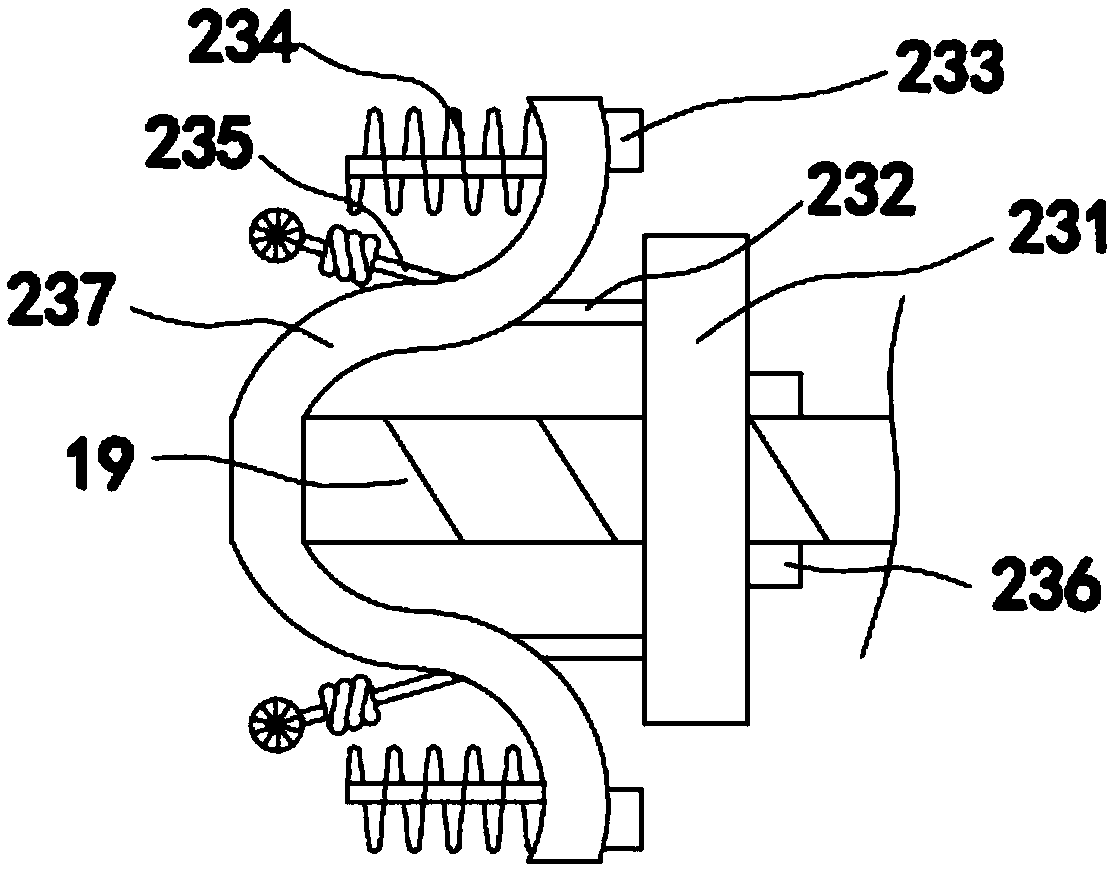

[0020] like Figure 1-3 As shown, a mechanical shrimp peeling tool includes a peeling drum 1 and a sheller 23. The left side of the peeling drum 1 is connected to the support frame 3 through the hinge block 2, and the bottom of the support frame 3 is embedded in the fixed base 6. The right end of the drum 1 is connected to the drive motor 10 , the output end of the drive motor 10 is connected to the screw rod 19 , and the surface of the screw rod 19 is covered with a sheller 23 and a moving plate 21 . The sheller and moving plate installed inside the shelling drum can gather the shrimps together for shelling, remove the shells quickly, and the shelled shrimps have high integrity, and can also reduce the vibration caused by the operation of the device. In order for the device to operate more stably, the peeling drum has better sealing performance, and the dust is not easy to enter during the peeling process, which ensures the hygienic condition of the shrimp during production. ...

Embodiment 2

[0029] In the actual use of a mechanical shrimp peeling tool of the present invention: shrimp enters the peeling drum 1 from the shrimp inlet 9, the water inlet pipe 14 enters the water through the nozzle 15 to wash the shrimp, and the driving motor 10 drives the screw rod 19 to rotate. The screw mandrel 19 drives the sheller 23 to slap the shrimp during the rotation process, and the shrimp shells are knocked off. The first strong magnet 17 and the second strong magnet 233 are attracted to each other, and the moving plate 21 moves to the left, and the shrimp is concentrated and improved. To improve the shelling efficiency of the shrimp shells, the air blowing holes 8 spray the shrimp shells, blow the shrimp shells to the right side of the peeling drum 1, the telescopic cylinder 12 works to drive the right side of the shelling drum 1 to tilt upward, and the shrimps pass through the discharge port 7 discharge, convenient for people to use.

[0030] The conventional techniques in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com