Laminated board edge-breakage-proof bench saw

An anti-collapse edge table saw and panel veneer technology, which is applied in the direction of circular saws, sawing components, sawing equipment, etc., can solve problems such as chipping of veneer panels, inconvenient veneer processing, and affecting the use and appearance of veneer panels. Reduce the possibility of chipping and facilitate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

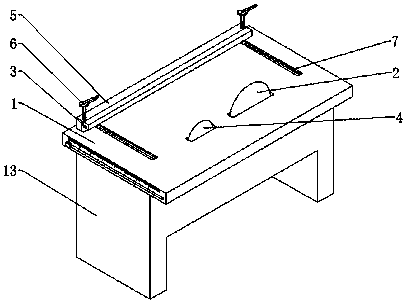

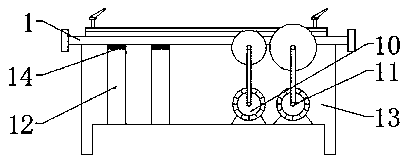

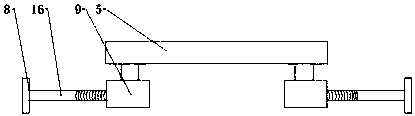

[0023] Example: such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, an anti-collapse edge table saw for veneer of the present invention comprises a cutting table 1, a table saw backer 5 and a base 13, two hand-tightened screws 6 are respectively arranged on both sides of the top of the table saw backer 5, two hand-tightened The bottom end of the screw 6 passes through the backer 5 of the table saw and is movably connected with a clamp block 3. The two ends of the bottom of the backer 5 of the table saw are respectively connected with two sliders 9 through fixed blocks. One end with threads is threaded, and the other ends of the two screw rods 16 pass through the corresponding rod grooves on the two side walls of the cutting table 1 and are fixedly connected with the two fastening screws 8. The chute 7, the cutting table 1 on the side of the table saw backer 5 are provided with two saw slots, and the two saw slots are respectively equipped with a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com