Internal centralized transverse prestress restraint masonry and prestress applying method thereof

A horizontal prestressing and centralized technology, which is applied in the processing of walls, buildings, and building materials, can solve the problems of poor seismic performance, high cost, and affecting the appearance of buildings, and achieve convenient construction, sufficient material supply, and mature construction technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

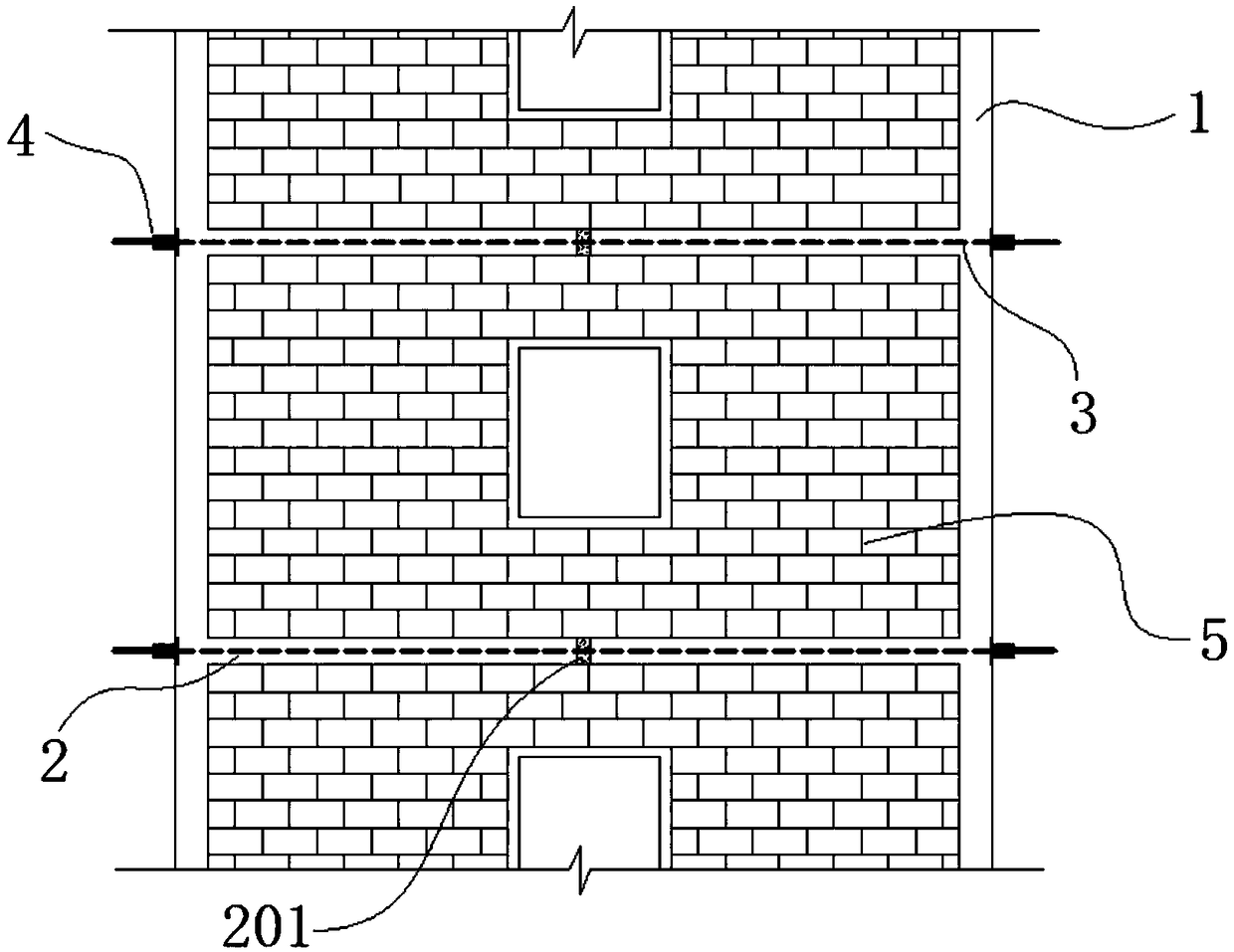

[0026] This embodiment discloses a built-in centralized lateral prestressed constrained masonry, which includes a house masonry provided with concrete structural columns 1 and concrete horizontal ring beams 2 . The concrete structural column 1 and the concrete horizontal ring beam 2 are cast-in-situ connected to jointly strengthen the integrity of the building.

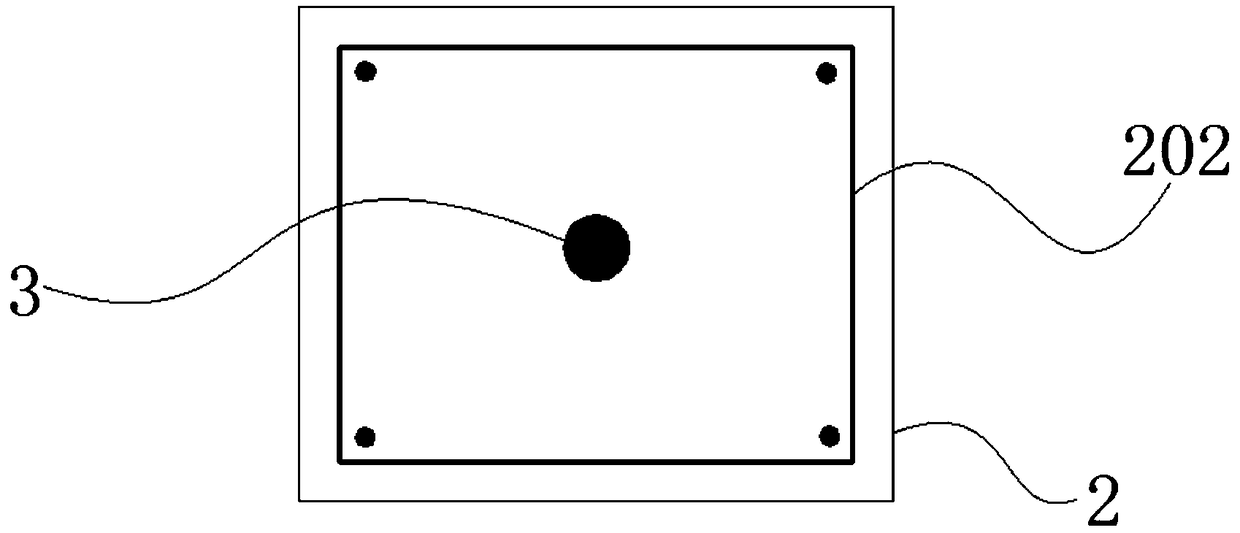

[0027] see figure 1 and figure 2 , the steel cage 202 of the concrete horizontal ring beam 2 is arranged with unbonded prestressed tendons 3 . The unbonded prestressed steel tendons 3 are arranged along the vertical and horizontal masonry walls of the house, forming a closed shape along the vertical and horizontal walls on the same floor. The tension end of the unbonded prestressed tendon 3 is arranged outside the concrete construction column 1 . The unbonded prestressed tendons 3 are prestressed at the tension end and anchored by prestressed anchors 4 .

[0028] The unbonded prestressed steel tendons 3 produce a...

Embodiment 2

[0031] A method for applying prestress to the built-in centralized transverse prestress constraint masonry according to claim 1, comprising the following steps:

[0032] 1) When binding the steel bars of the ring beam, the unbonded prestressed steel tendons 3 are concentratedly arranged in the reinforcement cage 202 of the concrete horizontal ring beam 2 .

[0033] 2) Concrete horizontal ring beam 2 is poured, and post-cast section 201 is reserved on the beam body of concrete horizontal ring beam 2 . Wherein, the width of the post-casting section 201 is 100mm-250mm, which meets the quality requirements of post-casting concrete.

[0034] 3) After the concrete of the concrete horizontal ring beam 2 reaches the design strength, the tensioning work of the unbonded prestressed tendons 3 is carried out.

[0035] 4) After the tensioning is completed, the concrete in the post-casting section 201 is poured, and the exposed prestressed anchor 4 is closed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com