Steel structure roof waterproof structure

A waterproof structure and steel structure technology, applied in the direction of roof insulation materials, etc., can solve the problems of poor waterproofness, complicated construction, large area of color steel tiles, etc., and achieve the effect of prolonging the service life, low construction cost and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

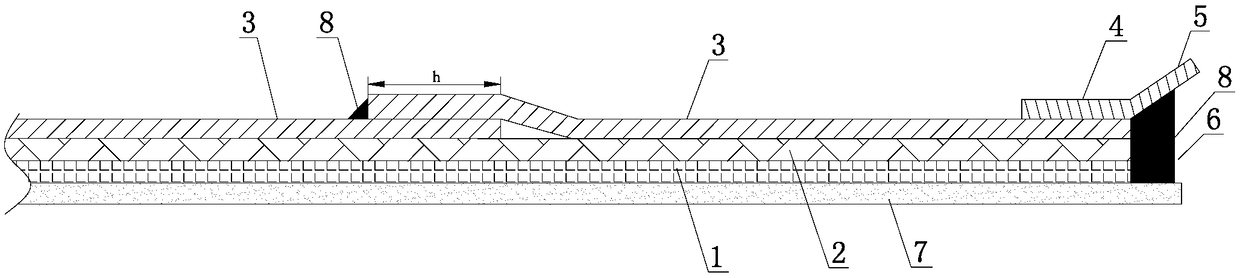

[0011] Such as figure 1 As shown, the waterproof structure of a steel structure roof includes a cold bottom oil bonding layer 1, a polyurethane waterproof base layer 2 and a high weather-resistant and corrosion-resistant waterproof surface layer laid on the steel structure roof 7 sequentially from bottom to top, The structure of the high weather-resistant and corrosion-resistant waterproof surface layer 3 includes: a number of self-adhesive waterproof rolls laid side by side on the upper surface of the polyurethane waterproof base, adjacent self-adhesive waterproof rolls overlap each other, and adjacent self-adhesive waterproof A sealant 8 for sealing the gap between the overlapping parts of the coils is provided; The edge of the layer is compressed and fixed to the edge bead 4, which can prevent the edge of the waterproof coiled material of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com