Residential exhaust duct system

A technology for exhaust ducts and exhaust pipes, applied in vertical pipes, sustainable buildings, buildings, etc., can solve the problem of smoke leakage, insufficient cement mortar at the joints of exhaust pipes, and smoke and air leakage at joints Improve the tensile strength and impact strength, reduce the risk of damage or chipping, and achieve good connection and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

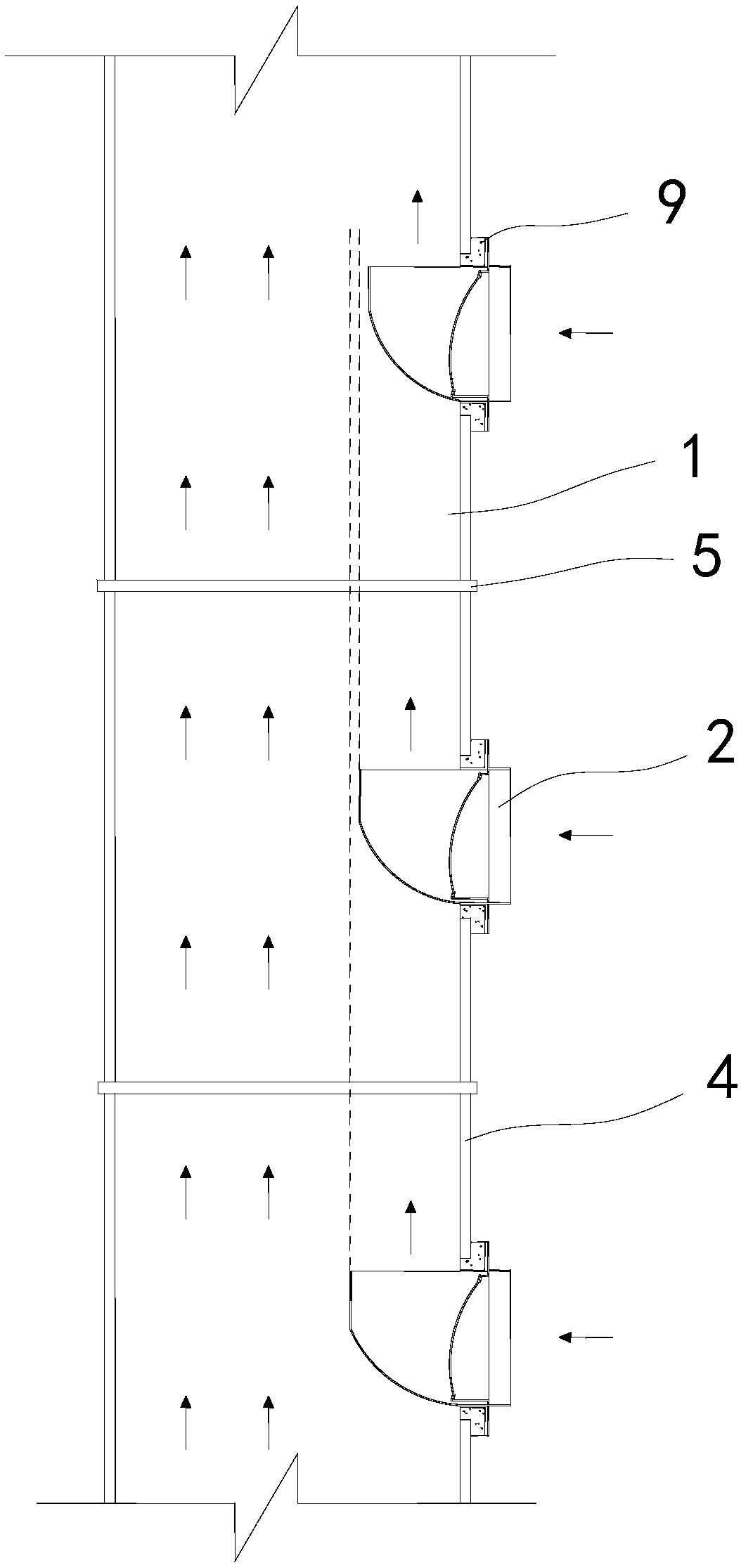

[0065] Such as figure 1 As shown in -10, a residential exhaust duct system includes a main exhaust duct 1 connected to the exhaust outlets of each floor, a flow guide device 2 arranged at the exhaust outlets of each floor, and a main exhaust duct 1 arranged at the exhaust outlet of each floor. Top hood device3.

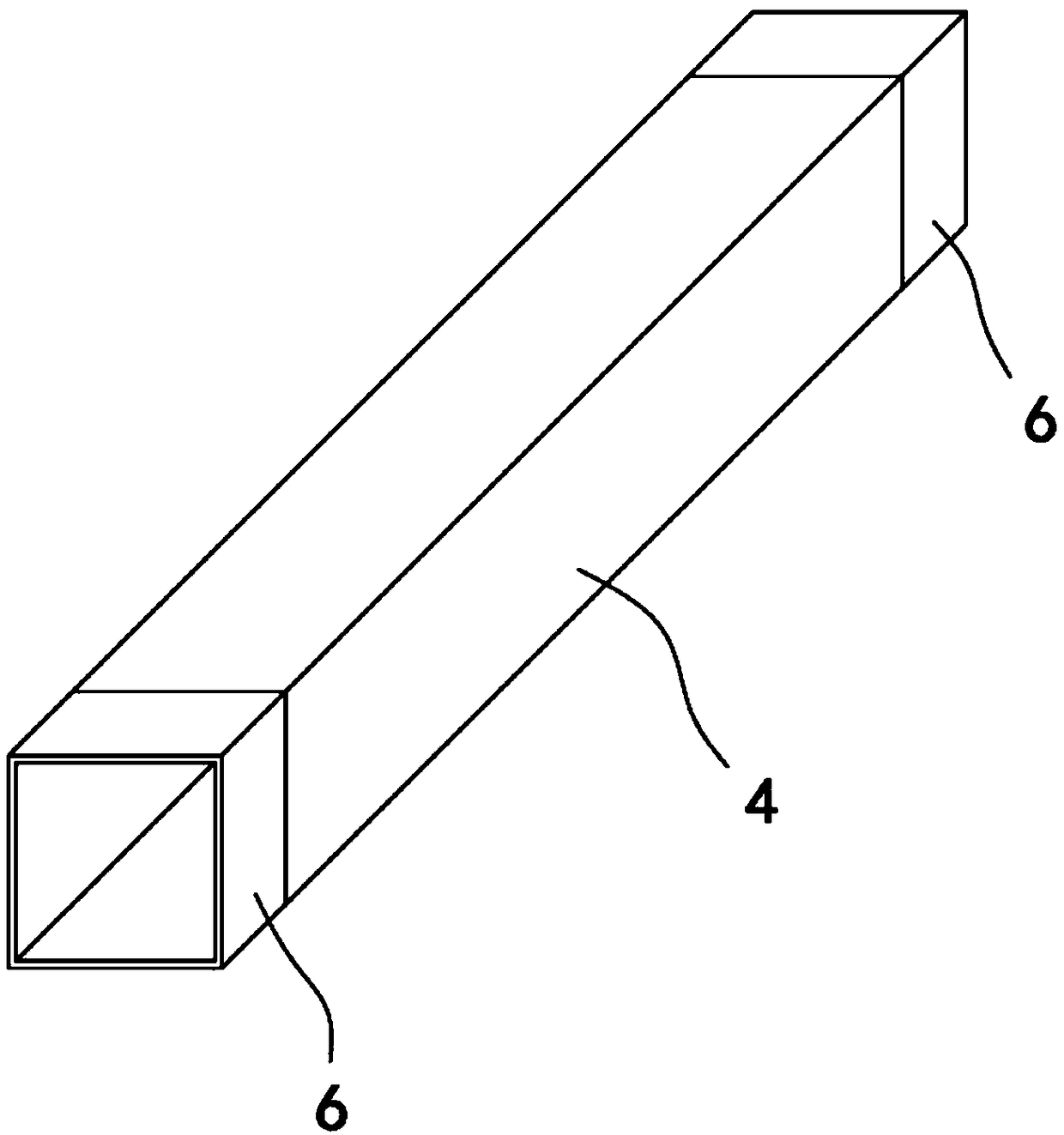

[0066] Among them, see figure 1 , the main exhaust duct 1 includes a plurality of prefabricated exhaust ducts 4, and the adjacent prefabricated exhaust ducts 4 are connected by connecting parts 5; the longitudinal section of the prefabricated exhaust ducts 4 in this embodiment is rectangular, and the prefabricated exhaust ducts The overall structure of the exhaust pipe 4 is as follows: figure 2 As shown, in other examples of the present invention, the longitudinal section of the prefabricated exhaust duct 4 may also be circular.

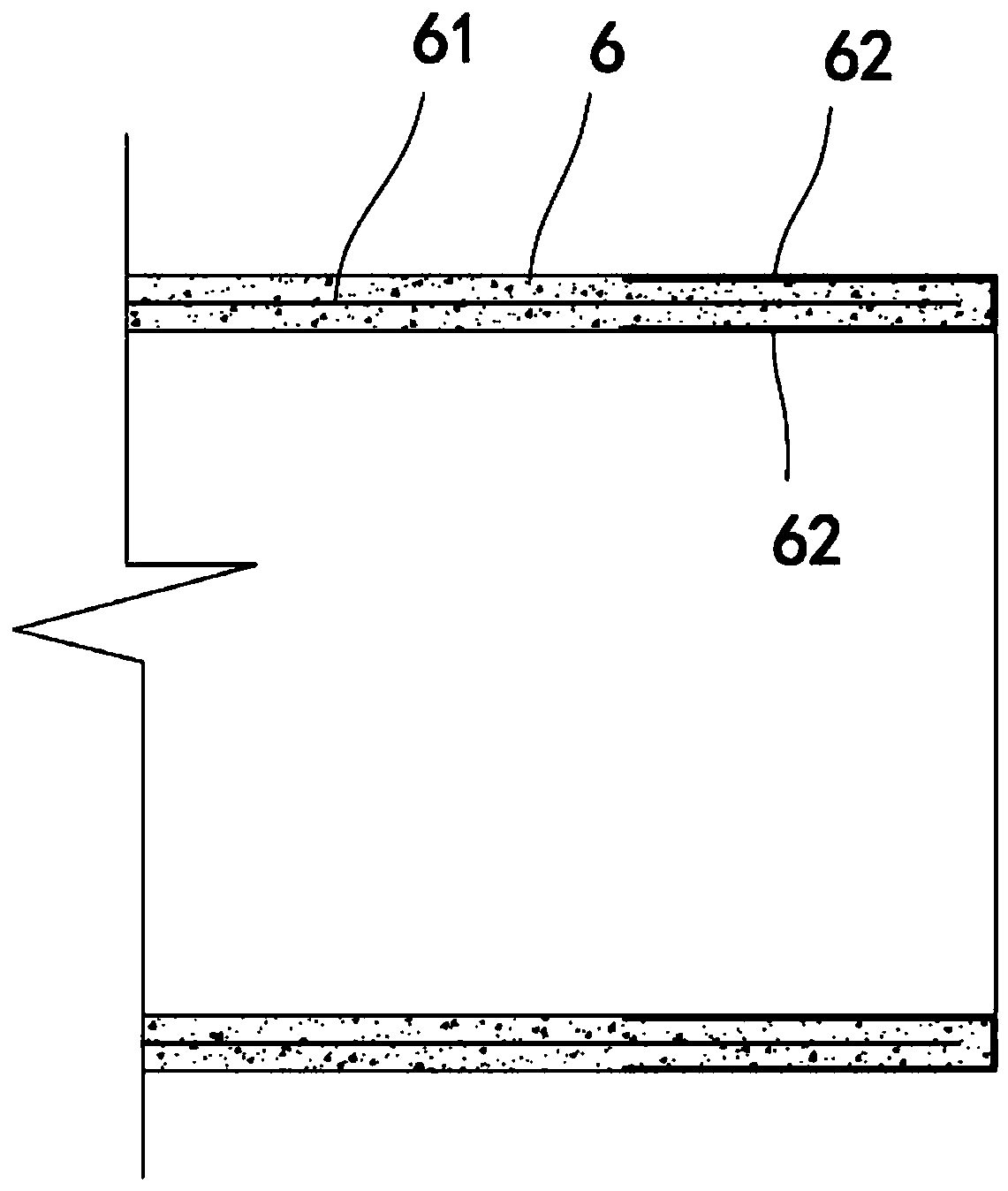

[0067] Specifically, a strength-reinforced area 6 is provided at the end of the prefabricated exhaust pipe 4 , and the strength-reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com