An aero-engine multi-stage low-pressure turbine rotor assembly measurement device and method

A low-pressure turbine and measurement method technology, applied in the direction of measuring devices, instruments, etc., can solve problems affecting positioning accuracy, etc., and achieve the effects of improving measurement accuracy, ensuring rotor coaxiality, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

[0023] In order to solve the problems of low positioning accuracy, low rotation accuracy, large data acquisition error in the installation process of the rotor disc and the stator casing in the prior art, which cannot meet the measurement accuracy requirements, and the unreliable rotor fixing method.

[0024] The present application provides a multi-stage low-pressure turbine rotor assembly measurement device and method for an aero-engine to solve the above problems.

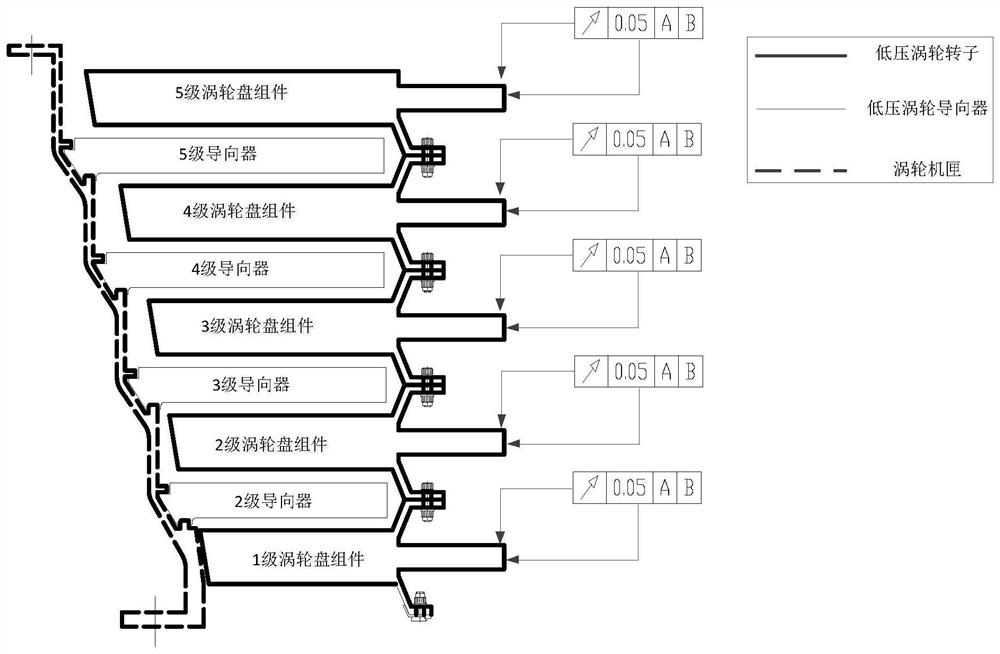

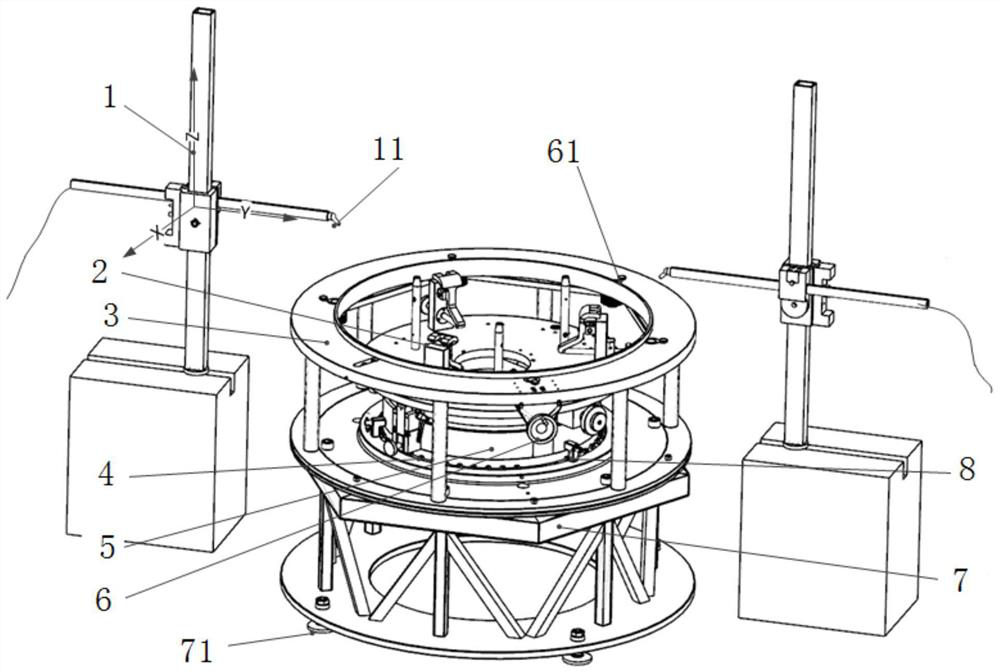

[0025] Such as figure 1 As shown, the main measuring mechanism 1, the rotor clamping mechanism 2, the stator supporting mechanism 3, the turntable bearing 4, the self-aligning and tilting platform 5, the synchronous lifting mechanism 6, the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com