Detection device for magnetic ring production processing

A detection device and magnetic ring technology, which is applied to measuring devices, instruments, etc., to achieve the effects of saving costs, improving work efficiency, and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

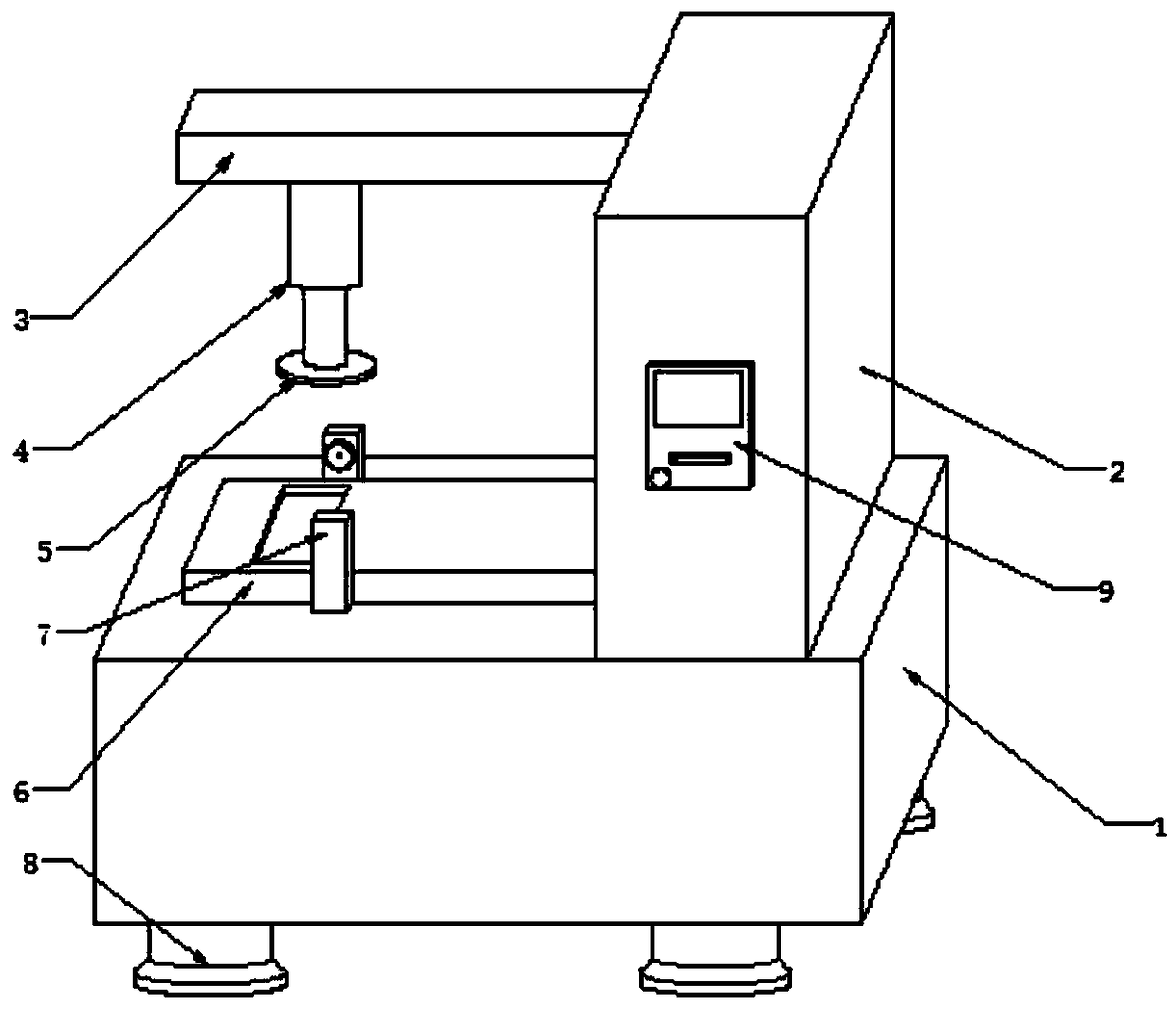

[0028] Embodiment one, with reference to Figure 1-6 , a detection device for magnetic ring production and processing, including a detection device protective shell 1, a display screen 901 including a cathode ray tube display screen, an ion display screen, a liquid crystal display screen, a start button 902 including a combination button, a jog button, a reset button, The support seat 8 is a connecting support seat, the rectangular horizontal rod 3 is a hollow fixed rod, the support seat 8 is arranged on the bottom outer wall of the protective casing 1 of the detection device, and the control cabinet 2 and the The magnetic ring detector 6, the center of the control cabinet 2 is connected with the fixed plate 9, and the fixed plate 9 is respectively provided with a display screen 901 and a start button 902, and the left side of the control cabinet 2 is connected with the rectangular horizontal bar 3, and the rectangular horizontal bar 3 A movable rod 4 is arranged on the inner ...

Embodiment 2

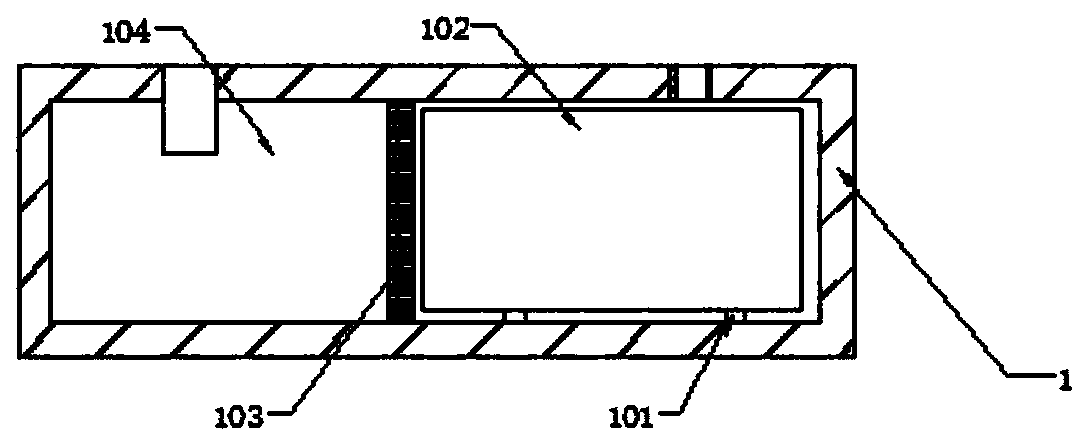

[0029] Embodiment two, refer to Figure 1-3 and Figure 5-6 , the display screen 901, the start button 902, the high-definition camera 701, and the lifting rod 702 are all electrically connected to the controller 204 through connecting wires, and pads 101 are arranged on the left and right sides of the bottom of the battery 102, and the pads 101 are connected with the detection The protective casing 1 of the device is connected, and a baffle 103 is arranged in the center of the protective casing 1 of the detection device, and the control cabinet 2 on the right side of the top of the protective casing 1 of the detection device is linked with the rectangular horizontal bar 3;

[0030] The staff activates the start button 902, the detection device operates, the lifting rod 702 rises, the high-definition camera 701 takes high-definition pictures of the surface of the magnetic ring, and the captured images are clearly displayed on the display screen 901, and the display screen 901 ...

Embodiment 3

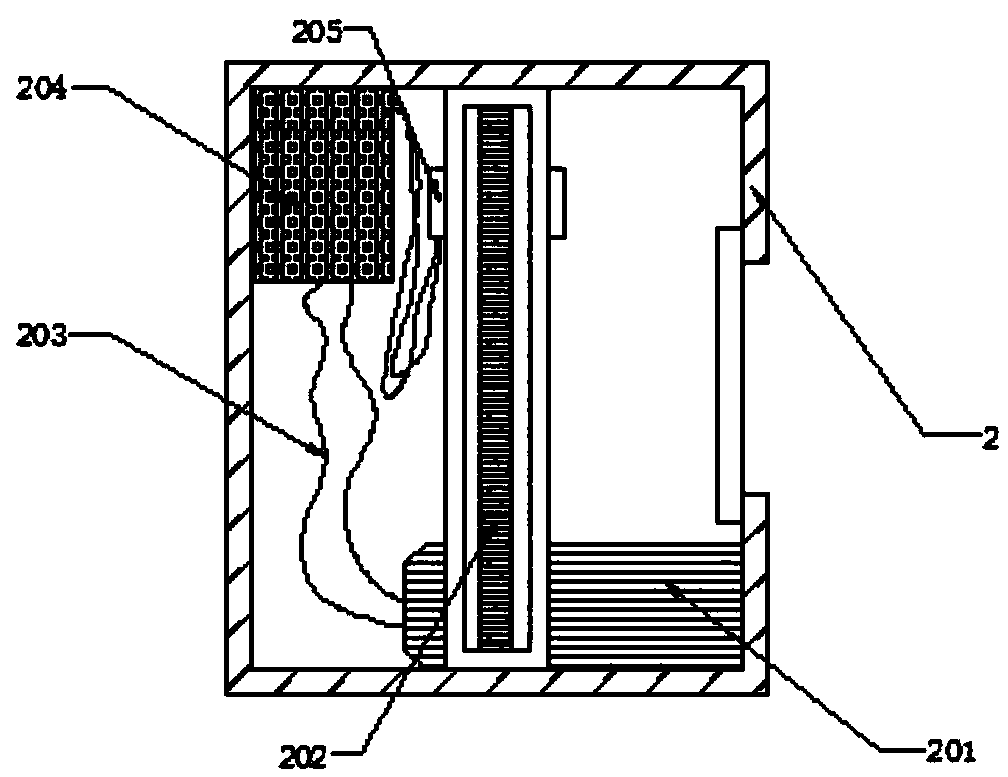

[0031] Embodiment three, refer to image 3 , the control cabinet 2 has a rectangular shape, the control cabinet 2 and the motor 201 on the left side of the inner bottom, the sliding device 202 at the middle part inside the control cabinet 2, the wire 203 on the left side of the motor 201, the controller 204 on the left side inside the control cabinet 2, The audio converter 205 behind the sliding device 202 is combined together;

[0032] During the use of the control cabinet 2, under the action of the motor 201 and the wire 203, the rectangular horizontal bar 3 can move up and down on the sliding device 202, and at the same time, the process of sliding the rectangular horizontal bar 3 under the action of the controller 204 Control, thereby enhancing the practicability of the detection device during operation, effectively replacing manual detection, improving work efficiency during the detection process, and saving costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com