A boiler steel structure space inspection method based on NX three-dimensional design software

A boiler steel structure, three-dimensional design technology, applied in the direction of design optimization/simulation, calculation, special data processing applications, etc., can solve the problem of boiler steel structure without research materials, academic papers or monographs, etc., to avoid repeated revisions of drawings, improve Effects of improving design quality and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

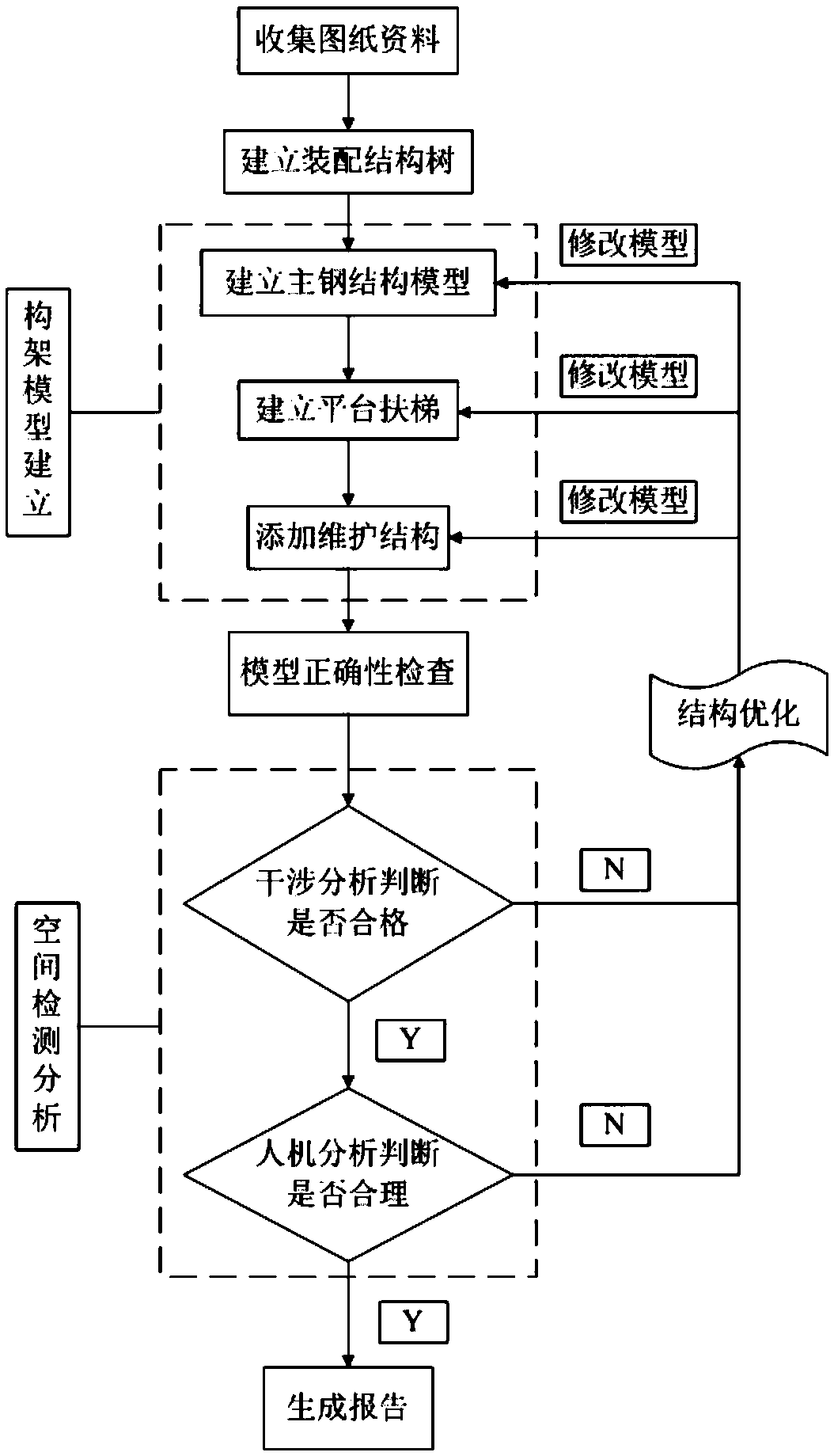

[0024] Such as figure 1 As shown, a boiler steel structure space detection method based on NX three-dimensional design software specifically includes the following process: Step 1, establish the boiler steel structure assembly structure tree, and complete the establishment of the entire boiler steel structure entity model; Step 2, in the entire In the coordinates of the boiler steel structure entity model, establish the main steel structure, platform escalator and maintenance structure; Step 3, check the correctness of the steel structure entity model; Step 4, perform a three-dimensional space interference check to determine whether there is interference between parts, If Y, no interference, the interference analysis is qualified, go to step 5; if there is interference, the interference analysis is unqualified, then obtain the interference, the location of the interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com