Pressing and releasing mechanism and method thereof

A technology of releasing mechanism and pressing seat, which is used in motor vehicles, aerospace equipment, aerospace aircraft, etc., can solve the problem of how many plates are pressed at a distance, and achieve a smooth extraction process, high rigidity and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

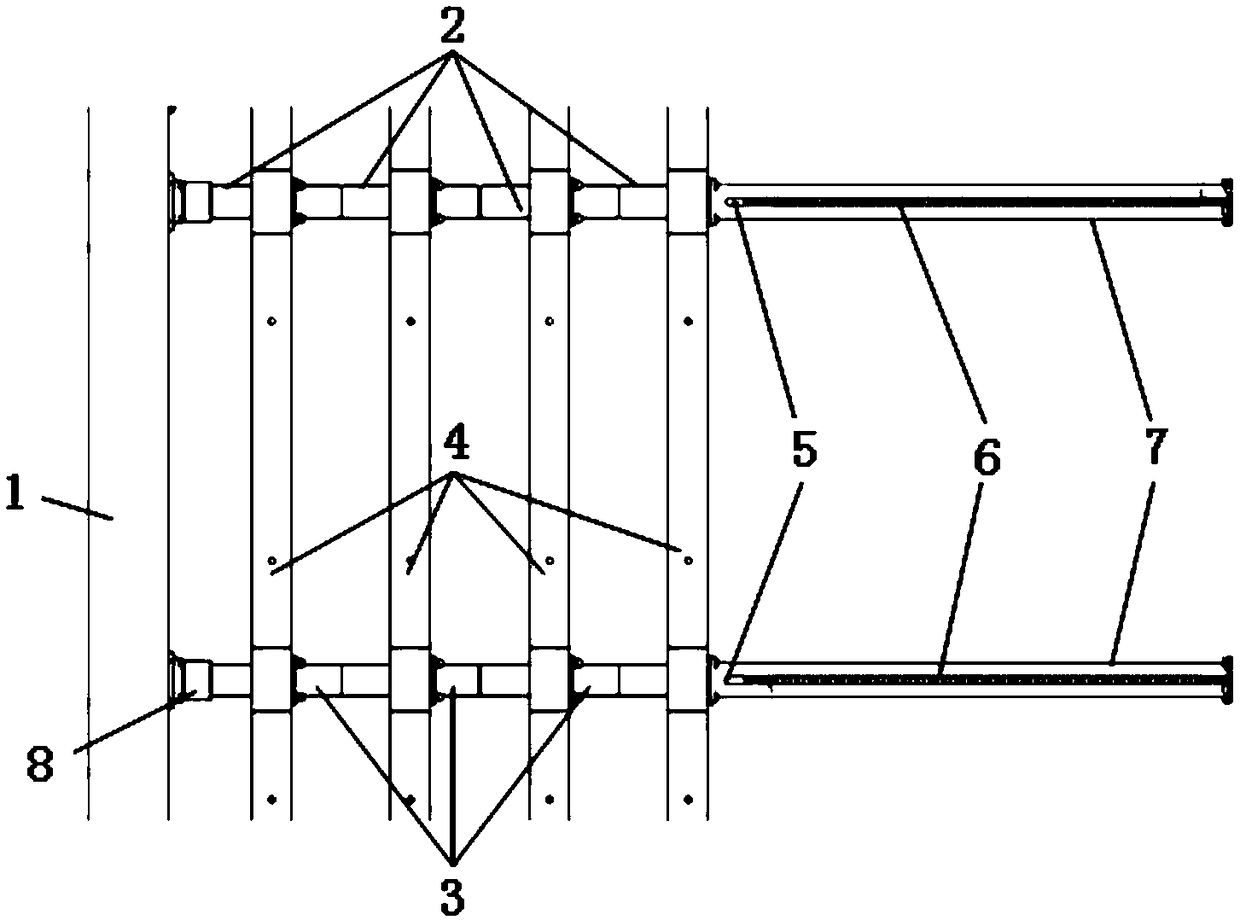

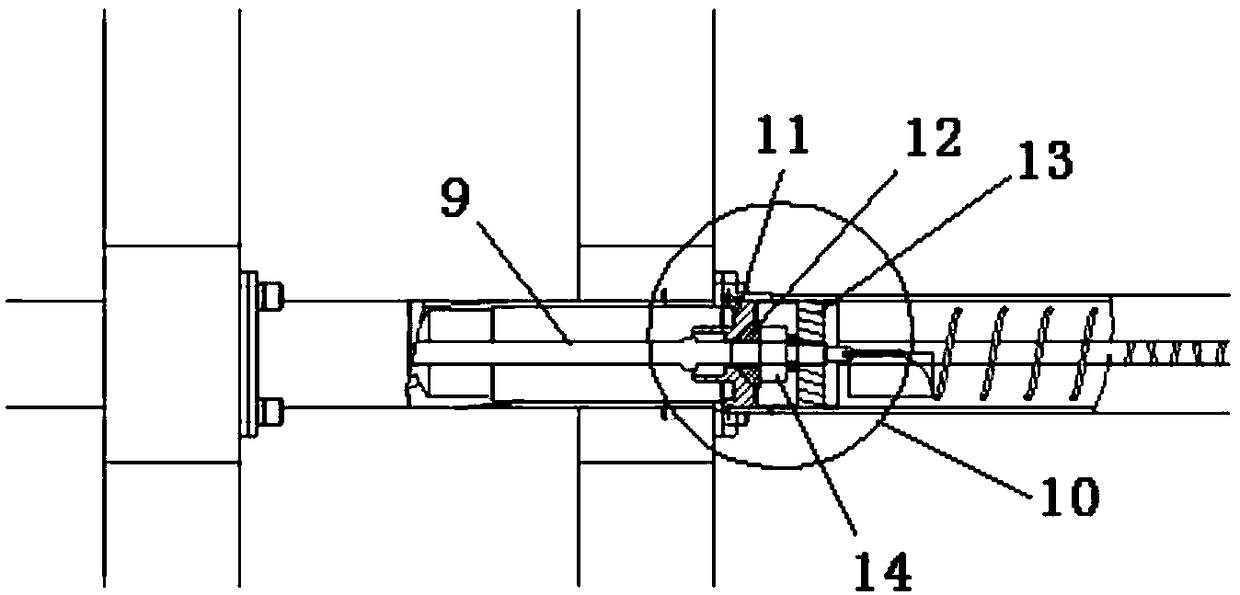

[0028] The following will combine Figure 1 ~ Figure 2 The compression release mechanism and method of the present invention will be described in further detail.

[0029] Due to the limitation of the size of the carrier envelope, the large-front payload on the spacecraft is usually divided into multiple sub-regions. During the launch process, the sub-regions are superimposed on each other, and the sub-regions are expanded after entering the predetermined orbit. The compression release mechanism is used to compress each sub-area during the launch process. After entering the predetermined track, the compression release mechanism releases the compression effect on each sub-area, and the release process should not affect the expansion of each sub-area.

[0030] figure 1 The above is a schematic diagram of the compression release mechanism of the preferred embodiment of the present invention.

[0031] See figure 1 , The compression release mechanism of this embodiment includes a base 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com