Compression release mechanism and method thereof

A technology of releasing mechanism and pressing seat, which is used in motor vehicles, space navigation equipment, space navigation equipment, etc., can solve the problem of how many plates are pressed at a distance, so as to ease the extraction process, avoid large-angle inclination, reduce The effect of small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

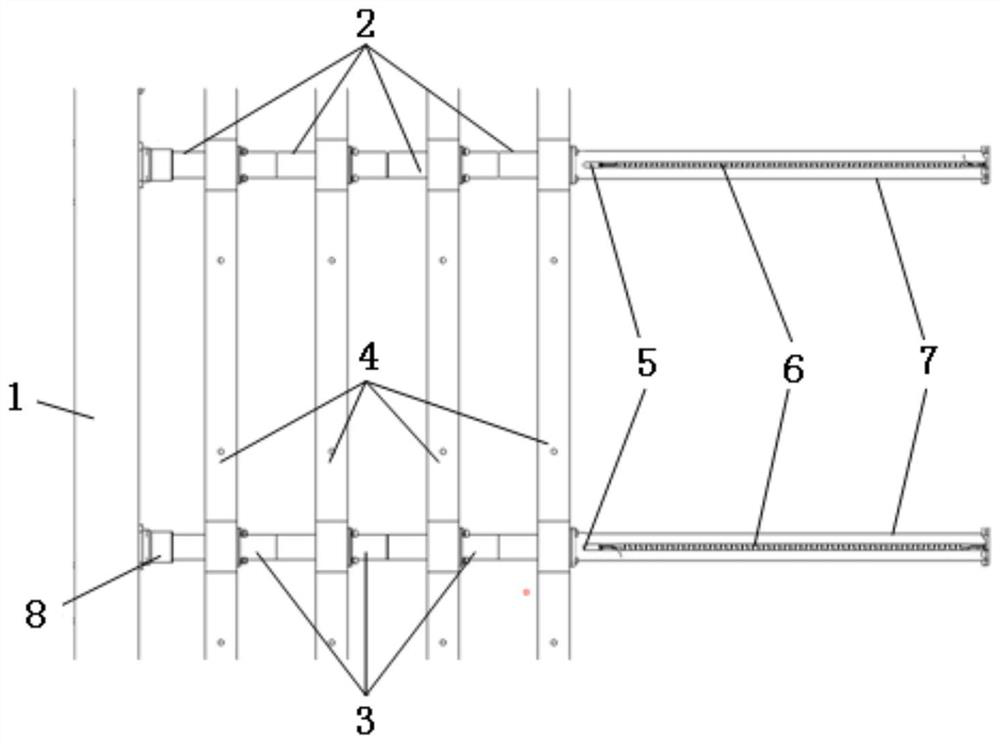

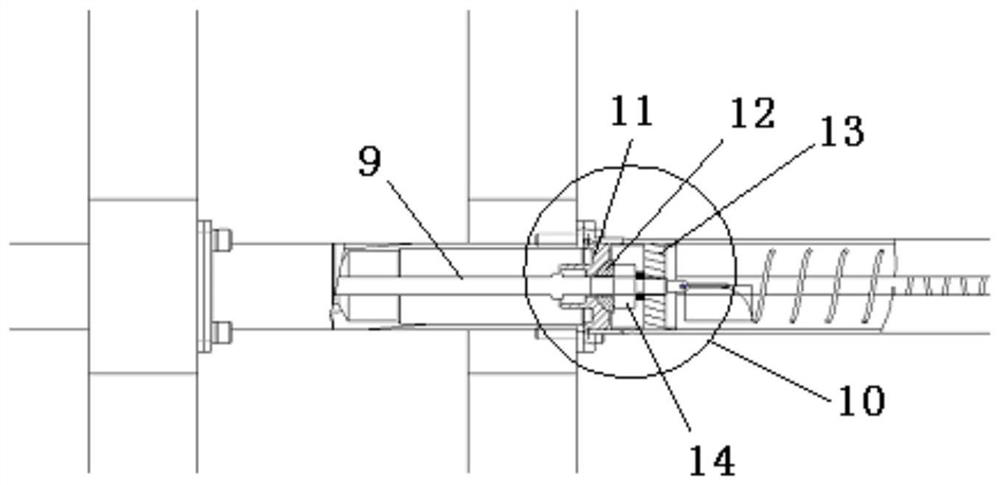

[0028] The following will combine Figure 1 ~ Figure 2 The compression release mechanism and its method of the present invention will be further described in detail.

[0029] Restricted by the size of the launch envelope, the large array payload on the spacecraft is usually divided into multiple sub-areas. During the launch process, the sub-areas are superimposed on each other, and each sub-area is expanded after entering the predetermined orbit. The compression release mechanism is used to compress each sub-area during the launching process. After entering the predetermined orbit, the compression release mechanism releases the compression effect on each sub-area, and the release process should not affect the expansion of each sub-area.

[0030] figure 1 The above is a schematic diagram of the compression release mechanism of the preferred embodiment of the present invention.

[0031] see figure 1 , the compression release mechanism of this embodiment includes a base 1, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com