Horizontal rotating mechanism and heliostat system

A horizontally rotating and rotating arm technology, applied in the field of solar energy utilization, can solve the problems of large-scale tracking of unfavorable sunlight, lower solar energy utilization efficiency, poor rotation stability, etc., to expand the ability of fixed date tracking, improve the ability of fixed date tracking, and expand the range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

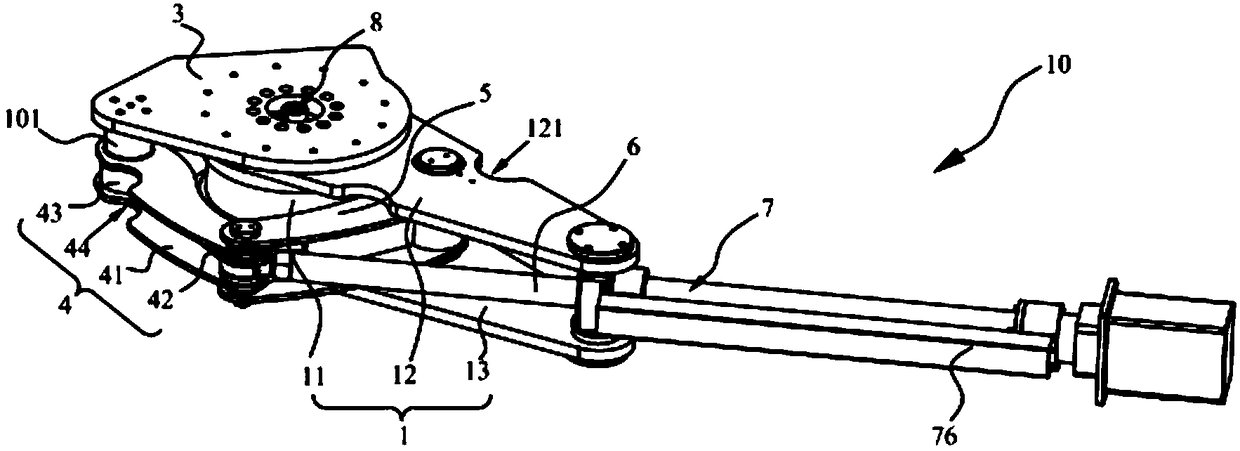

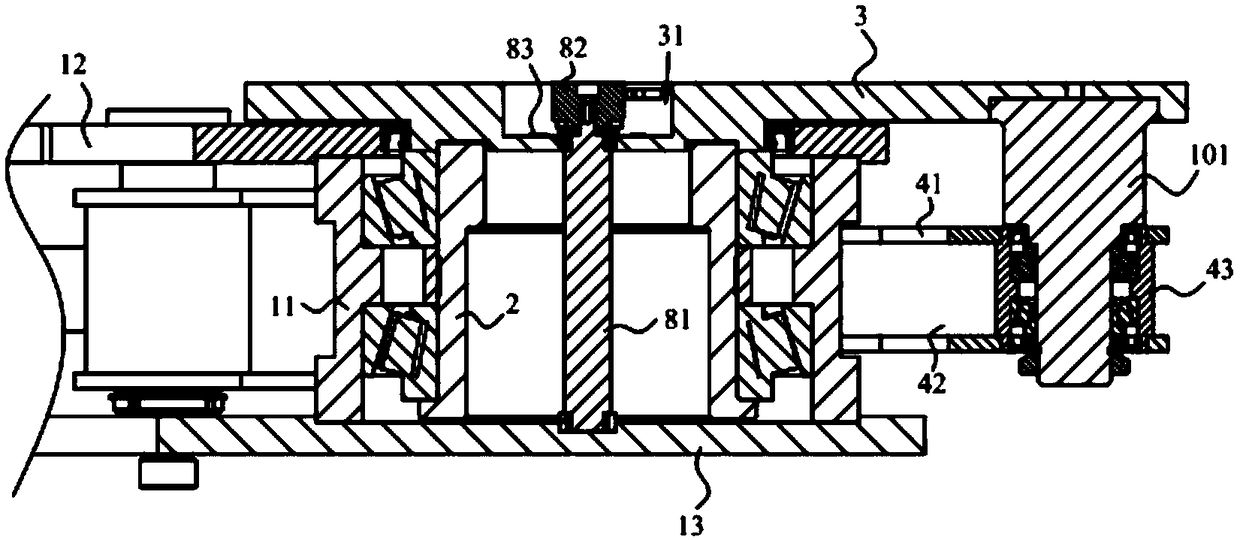

[0059] figure 1 Is a schematic structural diagram of a horizontal rotation mechanism 10 provided by an embodiment of the present invention, figure 2 A partial cross-sectional view of the horizontal rotation mechanism 10 provided by an embodiment of the present invention, such as Figure 1-2 As shown, this embodiment provides a horizontal rotating mechanism 10, which includes a fixed base 1, a rotating base 2, a rotating disk 3, a first rotating arm 4, a second rotating arm 5, and a horizontal drive assembly. The revolving base 2 is pivotally connected to the fixed base 1, and the revolving disc 3 is arranged above the revolving base 2 and is fixedly connected to the revolving base 2. The first rotating arm 4 is arranged on one side of the revolving base 2, and one end of the first rotating arm 4 is pivotally connected to the rotating disc 3; the second rotating arm 5 is arranged on the other side of the revolving base 2, and the second rotating arm 5 One end is pivotally connec...

Embodiment 2

[0103] This embodiment provides a horizontal rotation mechanism 10. Compared with the first embodiment, the horizontal rotation mechanism 10 provided in this embodiment is basically the same in composition and structure as the horizontal rotation mechanism 10 in the first embodiment. The difference lies in this The structure of the horizontal drive assembly provided by the embodiment is different from the structure of the horizontal drive assembly in the first embodiment. This embodiment only describes the structure that is different from the first embodiment, and will not repeat the description of the same structure as the first embodiment.

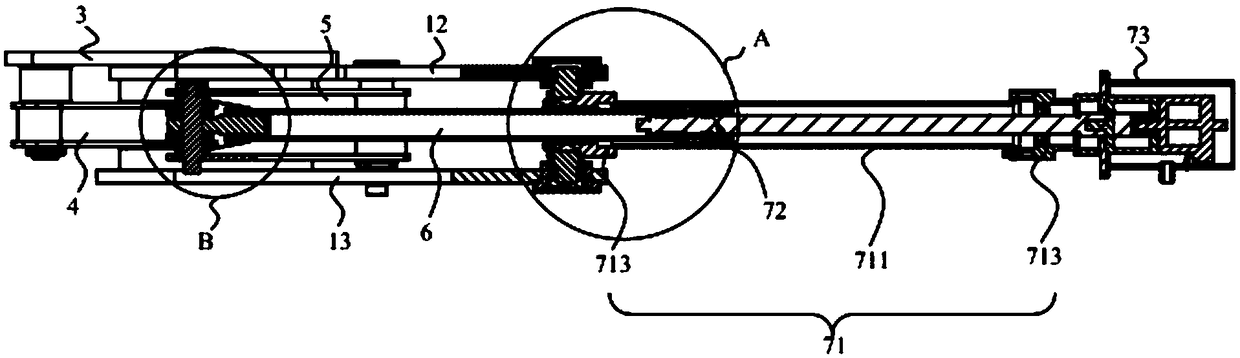

[0104] Image 6 Is a schematic structural diagram of a horizontal drive assembly provided by an embodiment of the present invention, Figure 7 It is a cross-sectional view of a horizontal drive assembly provided by an embodiment of the present invention. Such as Image 6 with 7 As shown, the horizontal drive assembly provided in this embodi...

Embodiment 3

[0113] Picture 12 Is a schematic structural diagram of a heliostat system provided by an embodiment of the present invention, Figure 13 for Picture 10 Partial enlarged view at middle E, such as Picture 12 with 13 As shown, this embodiment provides a heliostat system for tracking sunlight and acquiring and collecting solar energy. The heliostat system includes a mounting base 20, a support frame 30, a horizontal rotation mechanism 10, a pitch rotation mechanism 40, and a mirror 50. The mounting base 20 is used to support and fix the structure of the entire heliostat system, one end of which is fixedly connected to the ground, and the other end is connected to the horizontal rotation mechanism 10; the support frame 30 is used to support the connecting mirror 50, and the support frame 30 Connected with the horizontal rotation mechanism 10 and the pitch rotation mechanism 40; the horizontal rotation mechanism 10 is used to drive the support frame 30 and the reflector 50 to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com