A method for simulating the formation process of cold-rolled strip emulsion spots

A technology for cold-rolled strip steel and emulsion, applied in the field of steel cold-rolling, can solve problems such as affecting the quality of strip steel, affecting the production efficiency and economic benefits of enterprises, and reducing the qualified rate of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

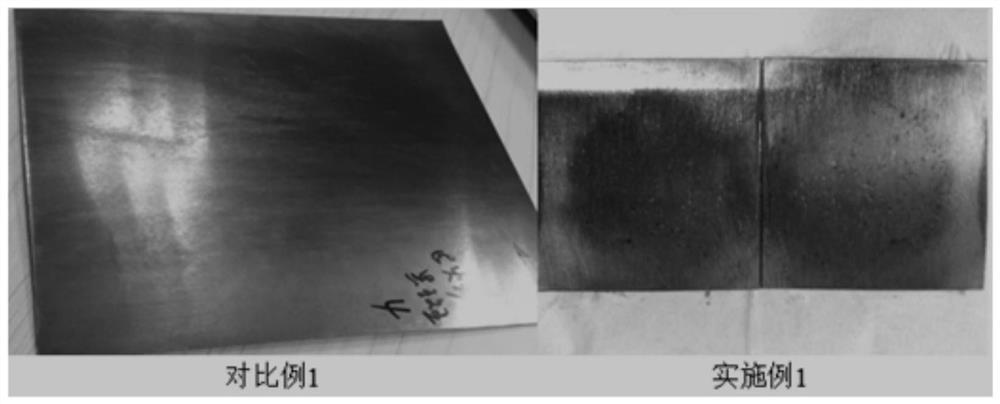

[0068] For the situation of Comparative Example 1, the formation process of the cold-rolled strip emulsion spot is simulated by the simulation method described in the present invention, so that the cold-rolled liquid can be selected and adjusted without affecting production, so as to reduce or even eliminate the cold-rolled strip surface The generation of emulsion spots improves the surface quality of cold-rolled strip products.

[0069] There is a huge pressure when the cold-rolled strip is rolled and crimped, which can reach 0.19 MPa according to calculations, and the surface temperature of the cold-rolled strip is relatively high, the highest temperature can reach 150°C, and the emulsion drips from the rolling outlet, so after crimping The surface of cold-rolled strip steel is in an environment of high pressure, high temperature, lack of oxygen, and water vapor.

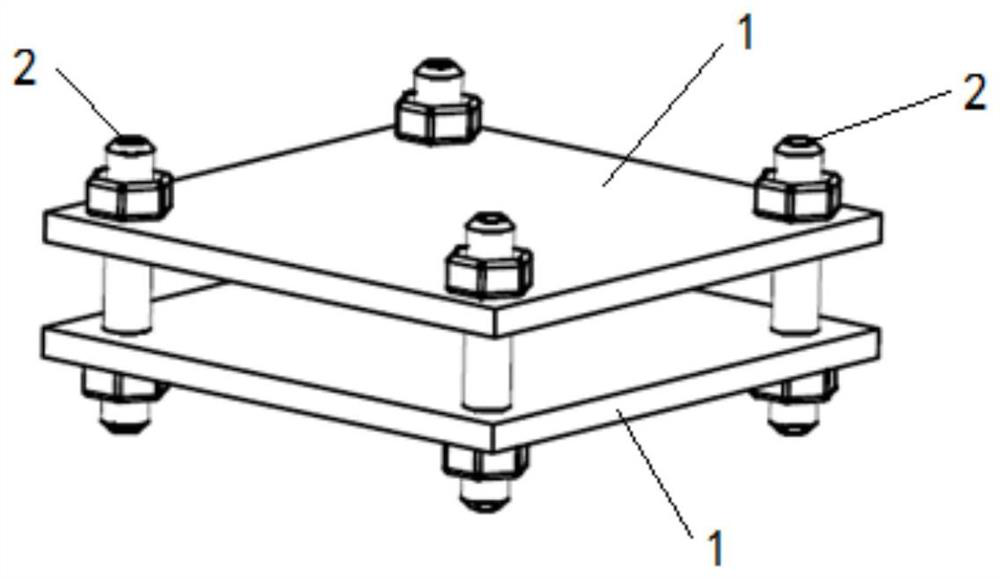

[0070] The present invention is as follows to the simulation process of above-mentioned working condition:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com