Optical product use determination system

A technology for consumer products and optical devices, applied in the field of optical determination systems for product usage, can solve problems such as time-consuming and labor-intensive, low-cost building management efficiency, and user disappointment, and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

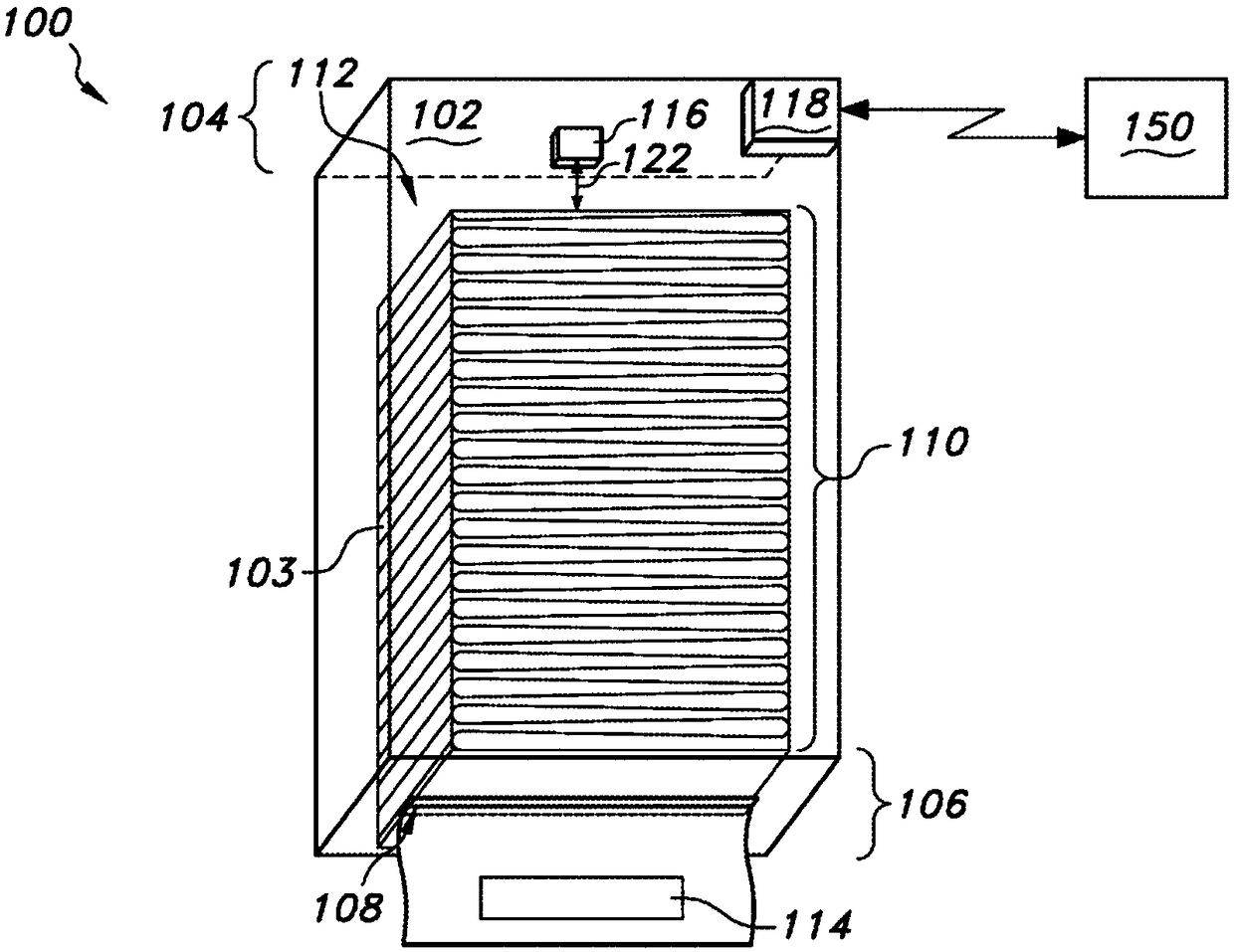

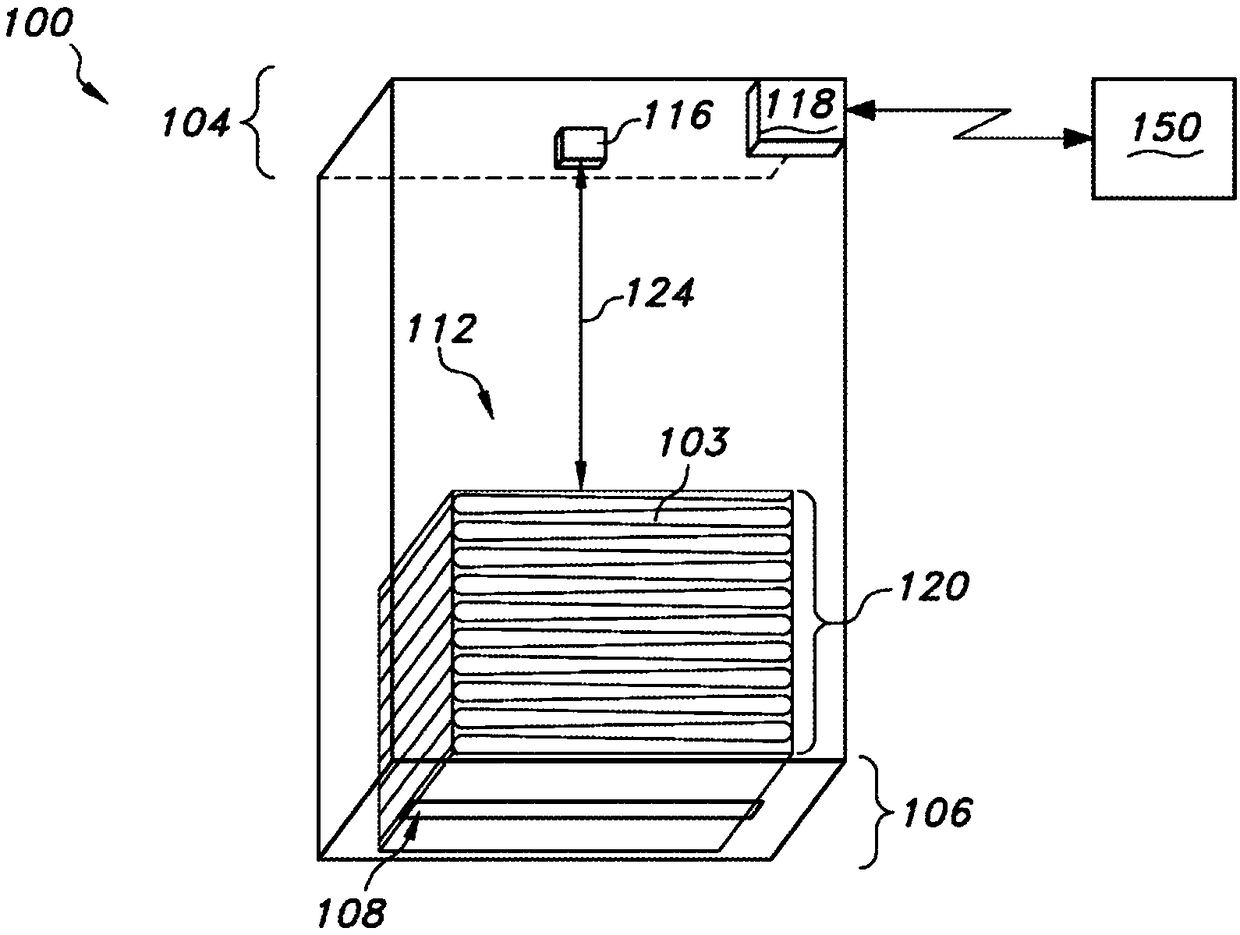

[0017] The present disclosure generally relates to optically determining how much product remains in a dispenser, such as a folded towel dispenser.

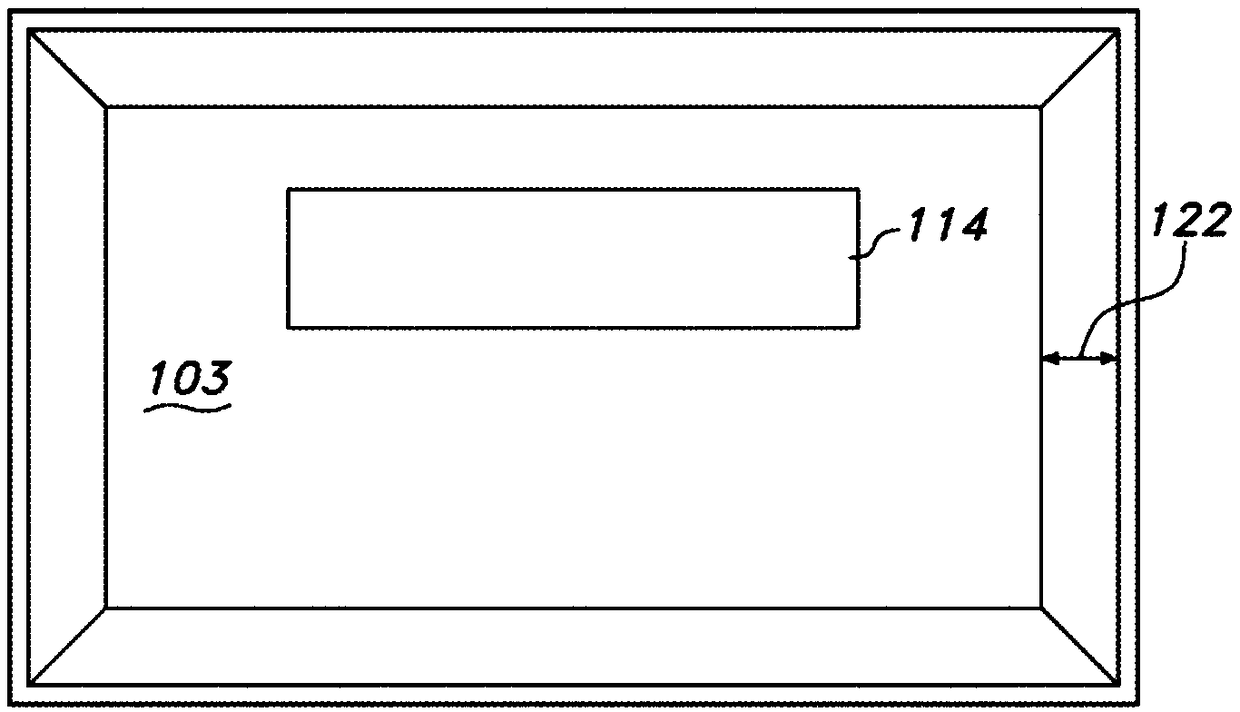

[0018] In some embodiments, the dispenser uses an optical device, such as a camera, to determine the amount of product remaining in the product dispenser, such as a stack of towels. For example, the dispenser uses characteristics of identification marks on the product (eg, the size of the product logo in the field of view of the optics, or image processing variables such as resolution or sharpness) to make such determinations.

[0019] As product is consumed, less product will remain and the level of product in the dispenser will correspondingly decrease. Then, in this example, as the product level decreases and the product (and the indicia on the product) moves further away from the camera mounted near the top of the dispenser, the identification indicia on the product will appear smaller to the camera.

[0020] Reference below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com