Rolling bearing unit

A technology of rolling bearings and bearings, applied in the field of rolling bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

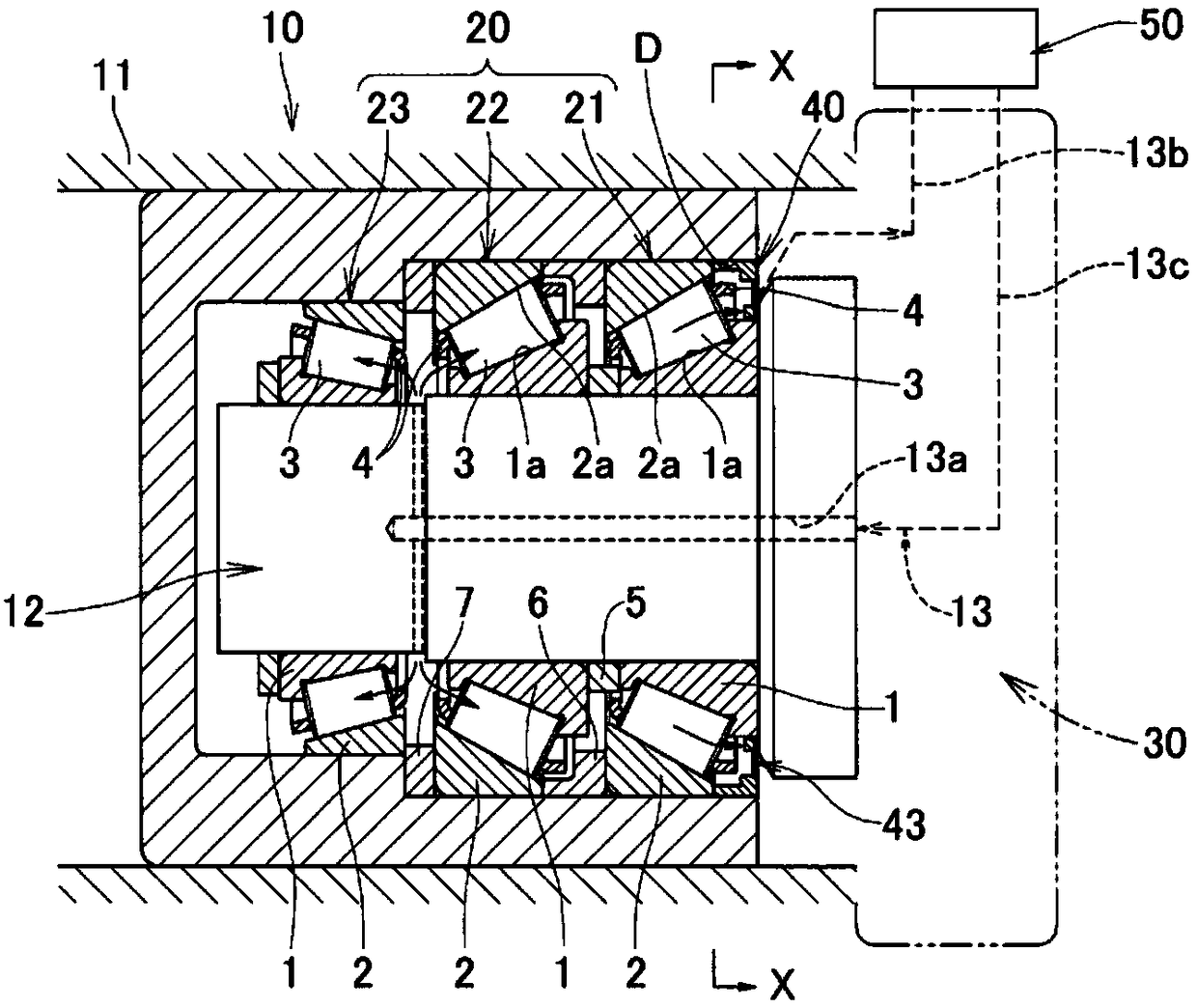

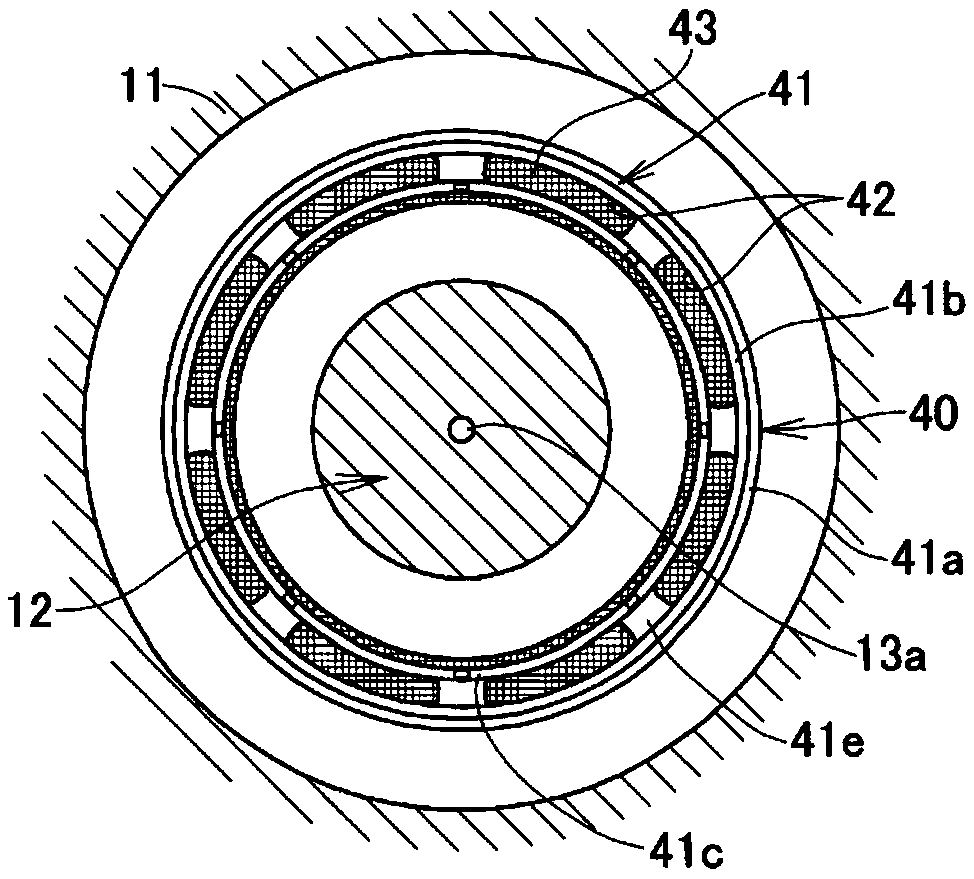

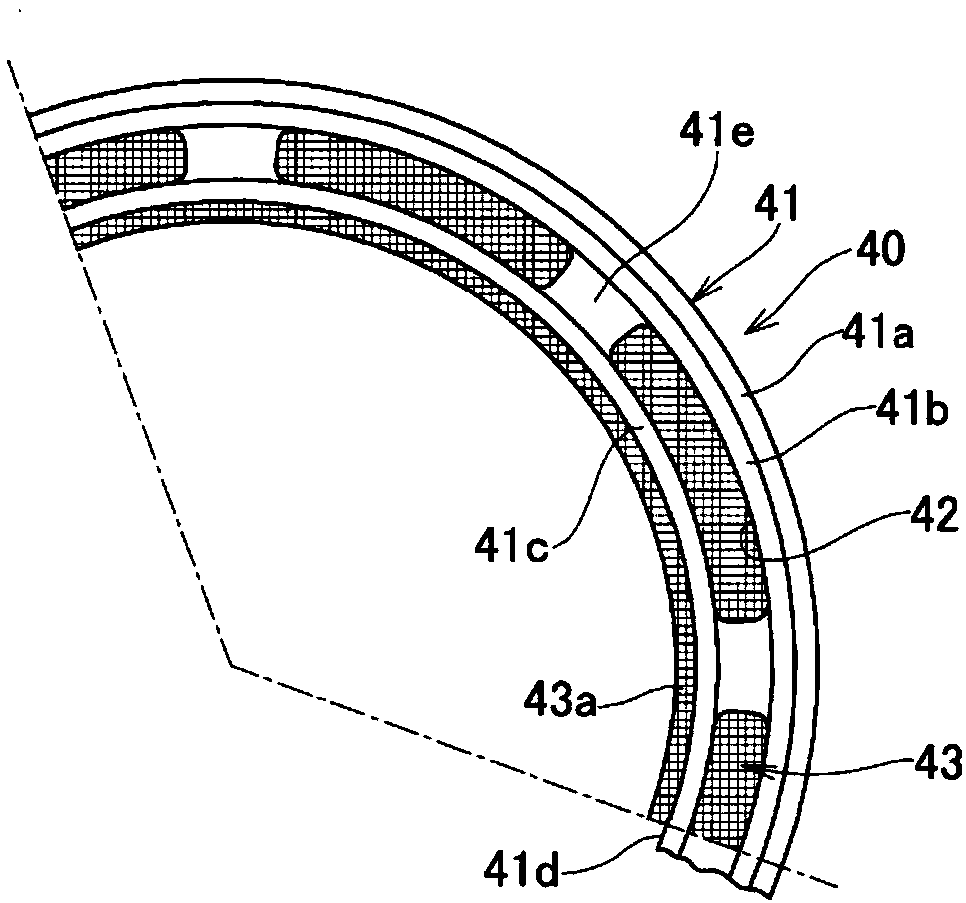

[0060] Below, based on the attached Figure 1 to Figure 19 , an embodiment of the rolling bearing of the present invention will be described by taking a casing used in an oil pump as an example.

[0061] figure 1 Numeral 10 is an oil pump, which has a bearing unit 20 and an operating mechanism unit 30 including a pump rotor (not shown) that sucks and compresses oil and discharges it.

[0062] The bearing unit 20 includes three rolling bearings 21 , 22 , and 23 arranged in parallel and lubricated with oil inside the casing 11 .

[0063] The rotating shaft 12 of the oil pump is supported by these rolling bearings 21 , 22 , 23 , and the pump rotor of the operating mechanism unit 30 is driven by the rotating shaft 12 to suck, compress, and discharge oil.

[0064] Each of the rolling bearings 21, 22, 23 is a well-known bearing including an inner ring (inner raceway) 1, an outer ring (outer raceway) 2, and a rolling bearing arranged between the raceway surfaces 1a, 2a of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com