Assembling device for castings

A technology for assembly devices and castings, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low centralization and high production costs, achieve simple structure, reduce production costs, and improve assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

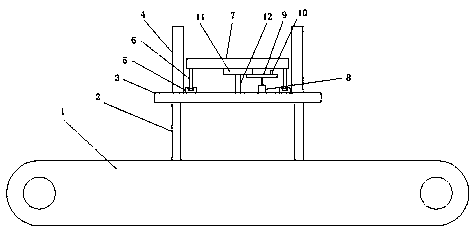

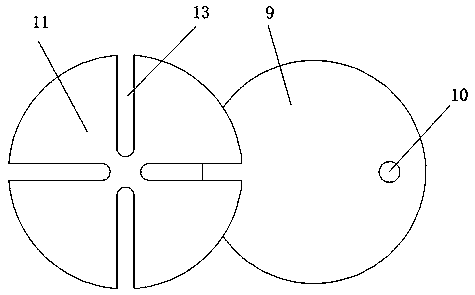

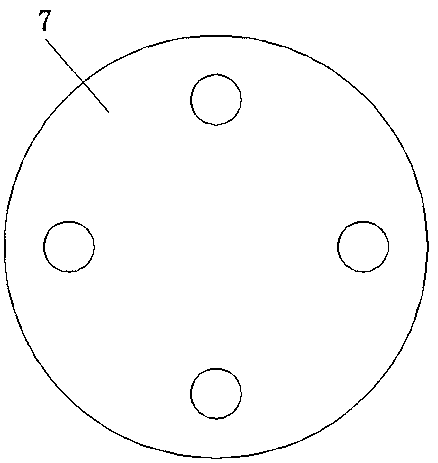

[0021] Embodiment: The castings are placed on the conveyor belt 1 in turn, and the conveyor belt 1 transmits the castings to the equipment at a certain speed, and then the operator places the castings in an assembly groove of the assembly plate 7, and the castings are completed by an assembly equipment 4. For the processing of the first process, turn on the motor 8 and set the program so that the rotation rate of the motor 8 is compatible with the transport rate of the conveyor belt 1. The motor drives the rotating plate 9 to rotate, and when the rotating plate 9 rotates for one revolution, it drives the moving block 10 to rotate for one revolution as well. , the moving block 10 will enter the groove 13 of the mounting block 11, so that the mounting block 11 rotates a quarter turn, thereby driving the assembly plate 7 to rotate a quarter turn, so that the casting moves to the position of the next assembly device 4, Then carry out the processing of the second process, and repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com