Pulley connecting structure used for guide rail elevator and guide rail elevator comprising pulley connecting structure

A technology for connecting structures and elevators, which is applied to the operating mechanism, manual mechanism, building structure and other directions of the wing fan, can solve the problems of reducing the operating efficiency of the elevator, difficult to guarantee the assembly accuracy, and high probability of failure, and achieves a reduction in the number of elevators. The weight of the pulley connection structure, the prevention of de-grooving defects, and the effect of a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

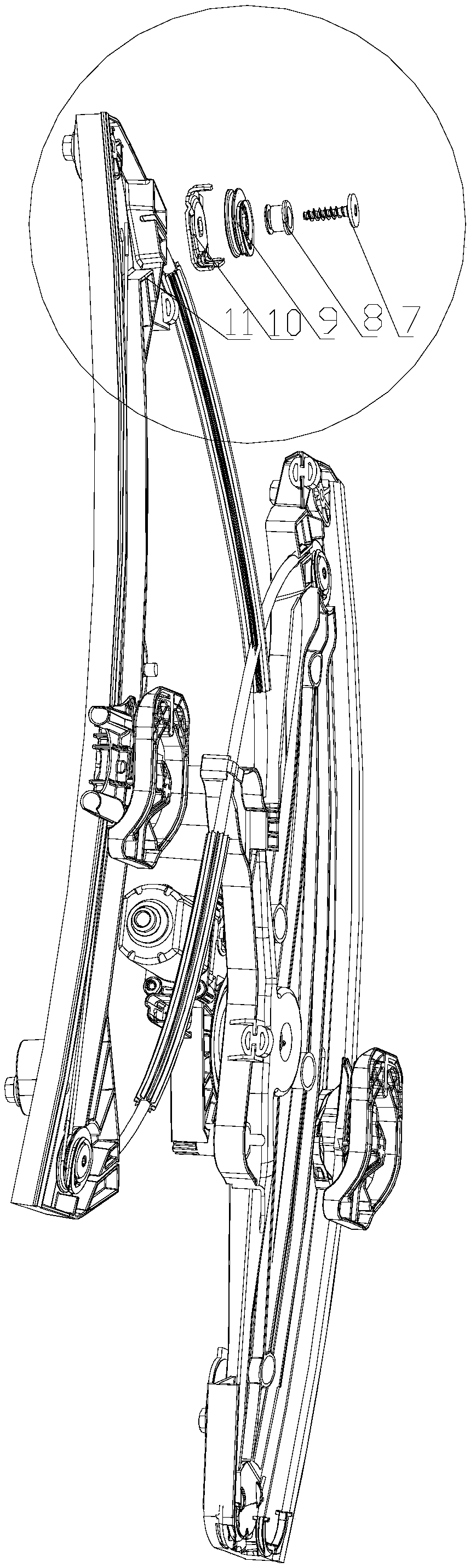

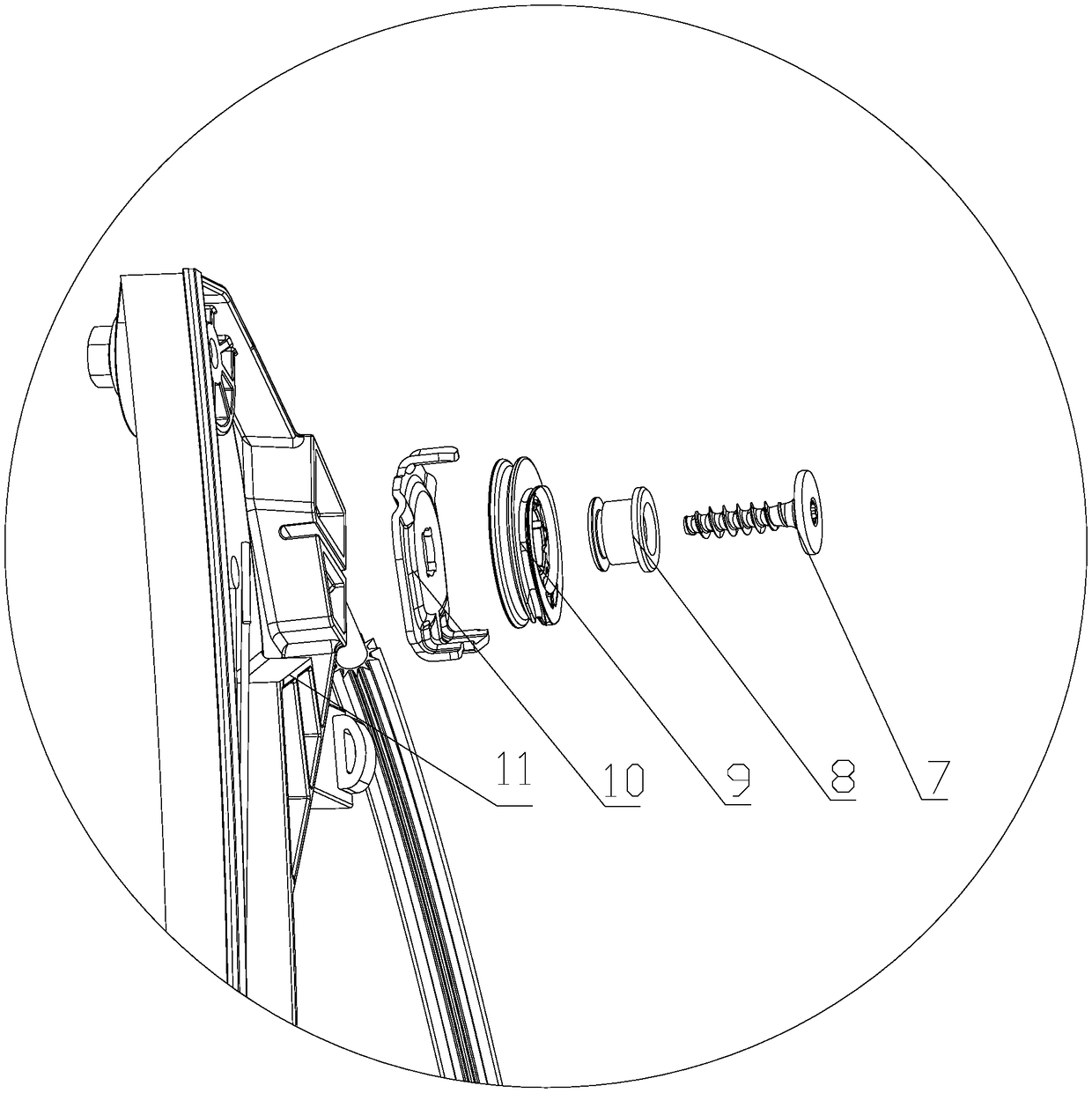

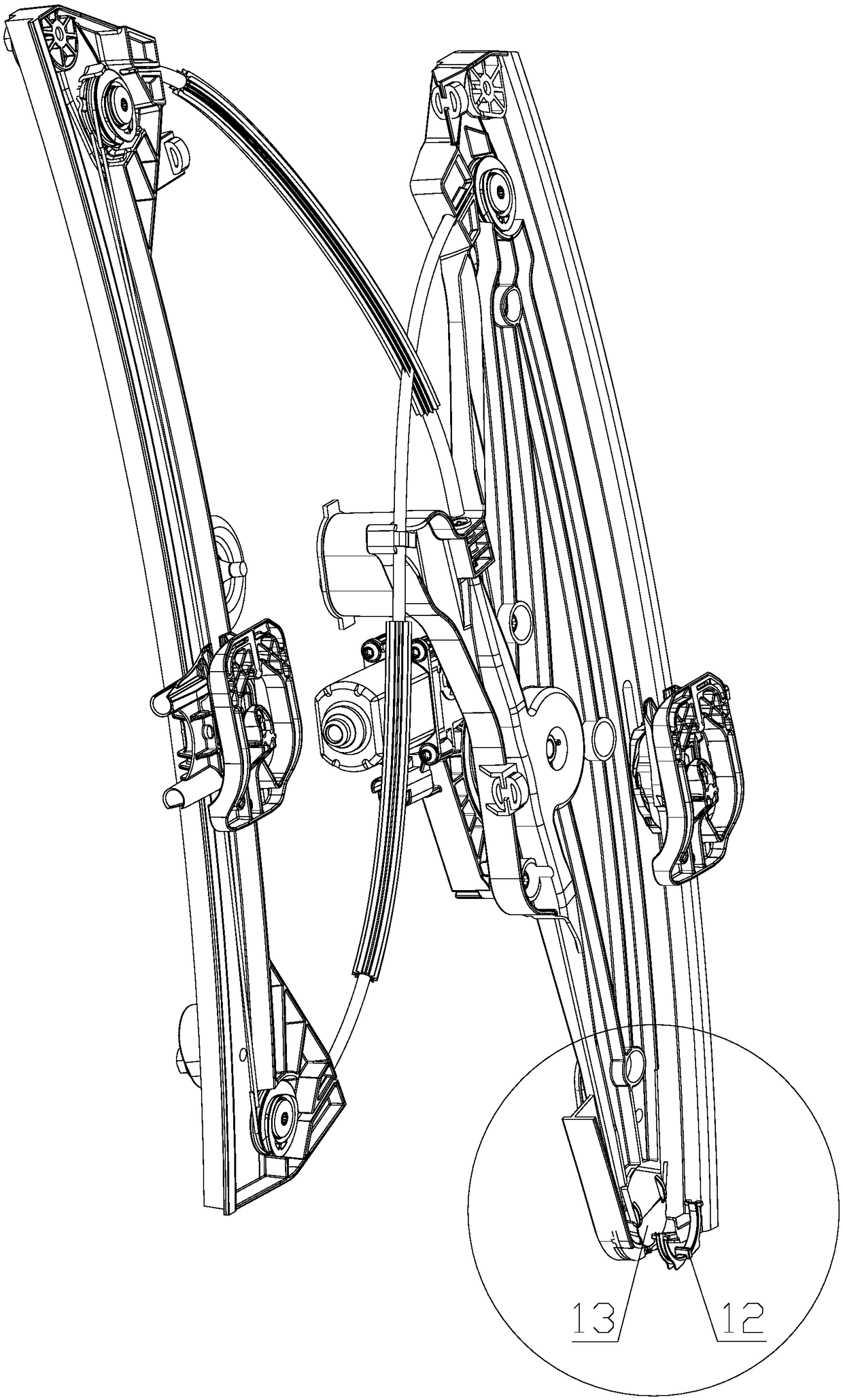

[0029] Such as Figure 5 ~ Figure 8 As shown, a pulley connection structure for a guide rail lifter, including an upper guide rail 11 and a cylindrical boss assembly 1, a metal ring 2, a pulley 3 and self-tapping screws A4, and the cylindrical boss assembly 1 is fixed on the upper guide rail 11 top, the cylindrical boss assembly 1 includes a boss base and a cylindrical boss fixed at the center of the boss base, the boss base of the cylindrical boss assembly 1 is arranged and fixed around the cylindrical boss with several support ribs, the cylindrical The cylindrical boss of the cylindrical boss assembly 1 is covered with a metal ring 2. The metal ring 2 can effectively prevent the cylindrical boss of the cylindrical boss assembly 1 from being crushed. The pulley 3 is rotated and installed on the outside of the metal ring 2. The pulley 3 has a lead-in structure, and the lifting rope can automatically wind into the groove of the pulley 3 through the lead-in structure of the pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com