A composite elastic element with multiple free surfaces

A technology of elastic elements and elastic parts, applied in the direction of springs/shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of insufficient axial stiffness and low radial stiffness, etc., to reduce rubber stress, reduce Radial stiffness, effect of improving fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

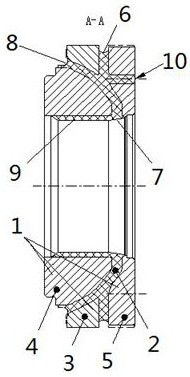

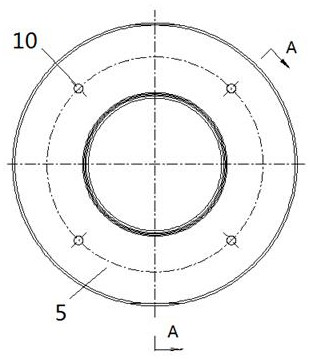

[0030] It can be seen from the accompanying drawings that the present invention relates to a composite elastic element with multiple free surfaces, including a metal part 1 and an elastic part 2, and the metal part 1 and the elastic part 2 are combined to form a composite elastic element; it is characterized in that: composite elastic The metal part 1 of the element includes a metal outer ring 3, a metal inner ring 4 and a metal side ring 5, the metal outer ring 3 and the metal side ring 5 are arranged in parallel in the axial direction, and there is a gap between the metal outer ring 3 and the metal side ring 5 in the axial direction, The metal inner ring 4 is located on the inner surface of the inner diameter of the metal outer ring 3, and the metal inner ring 4 is also arranged axially parallel to the metal side ring 5 in the metal outer ring 3, and the metal inner ring 4, the metal outer ring 3 and the metal side ring 5 There is also a gap between the metal outer ring 3, th...

Embodiment 2

[0039] The principle of the second embodiment is the same as that of the first embodiment, only slightly different in structure. It is a multi-free surface composite elastic element, including metal parts and elastic parts, and the metal parts and elastic parts are combined to form a composite elastic element; it is characterized in that: the metal part of the composite elastic element includes a metal outer ring, a metal inner ring and The metal side ring, the metal outer ring and the metal side ring are arranged in parallel in the axial direction, there is a gap in the axial direction between the metal outer ring and the metal side ring, the metal inner ring is located on the inner surface of the inner diameter of the metal outer ring, and the metal inner ring is also in the metal outer ring Arranged in parallel with the metal side ring axially, there is also a gap between the metal inner ring, the metal outer ring and the metal side ring; in the gap formed by the metal outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com