An anti-shock water-cooled brushless motor, motor pump unit and high-pressure cleaning equipment

A brushless motor, water-cooled technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as damage to onboard electronic components, solve electrical safety problems, solve high-temperature demagnetization problems, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

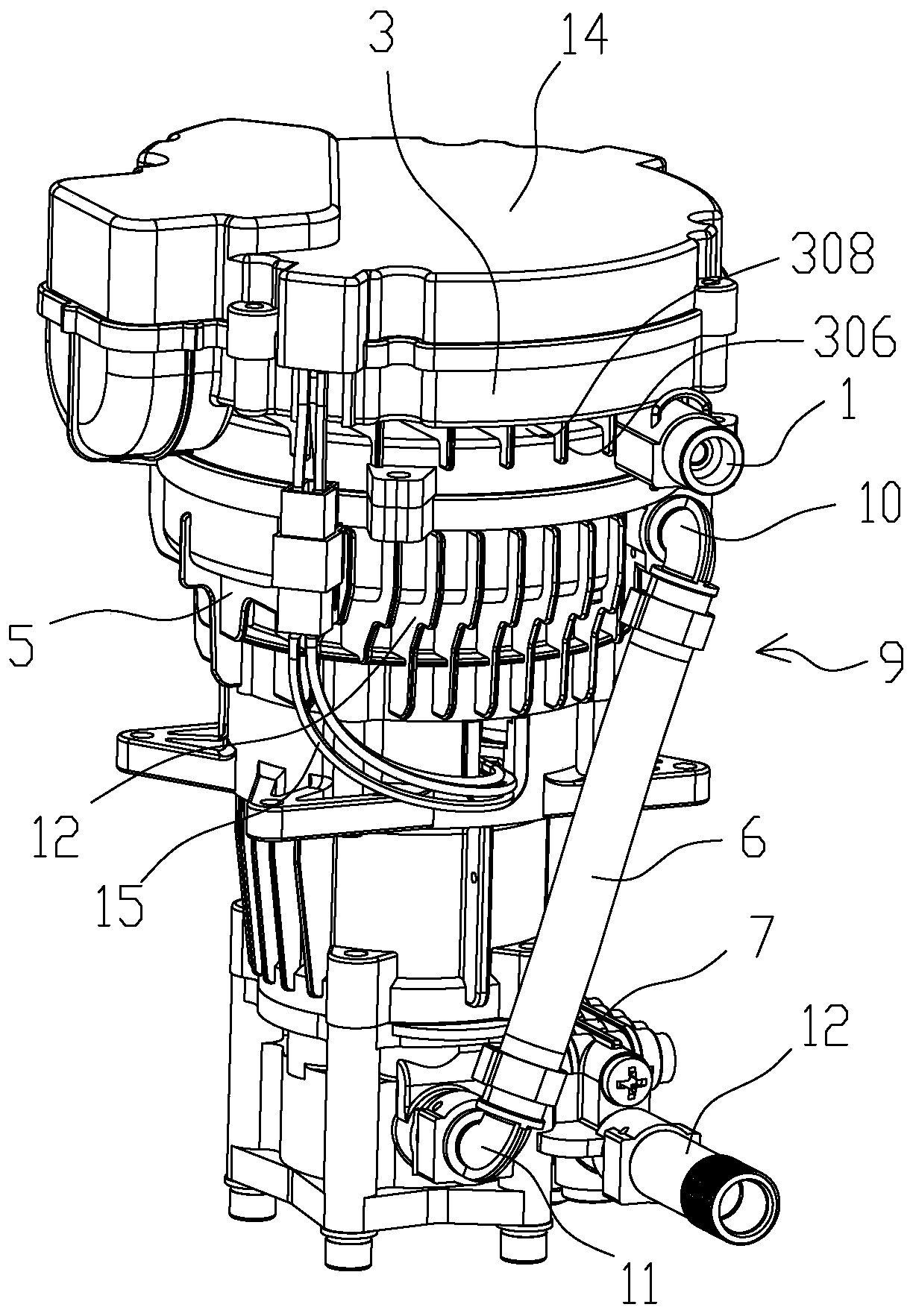

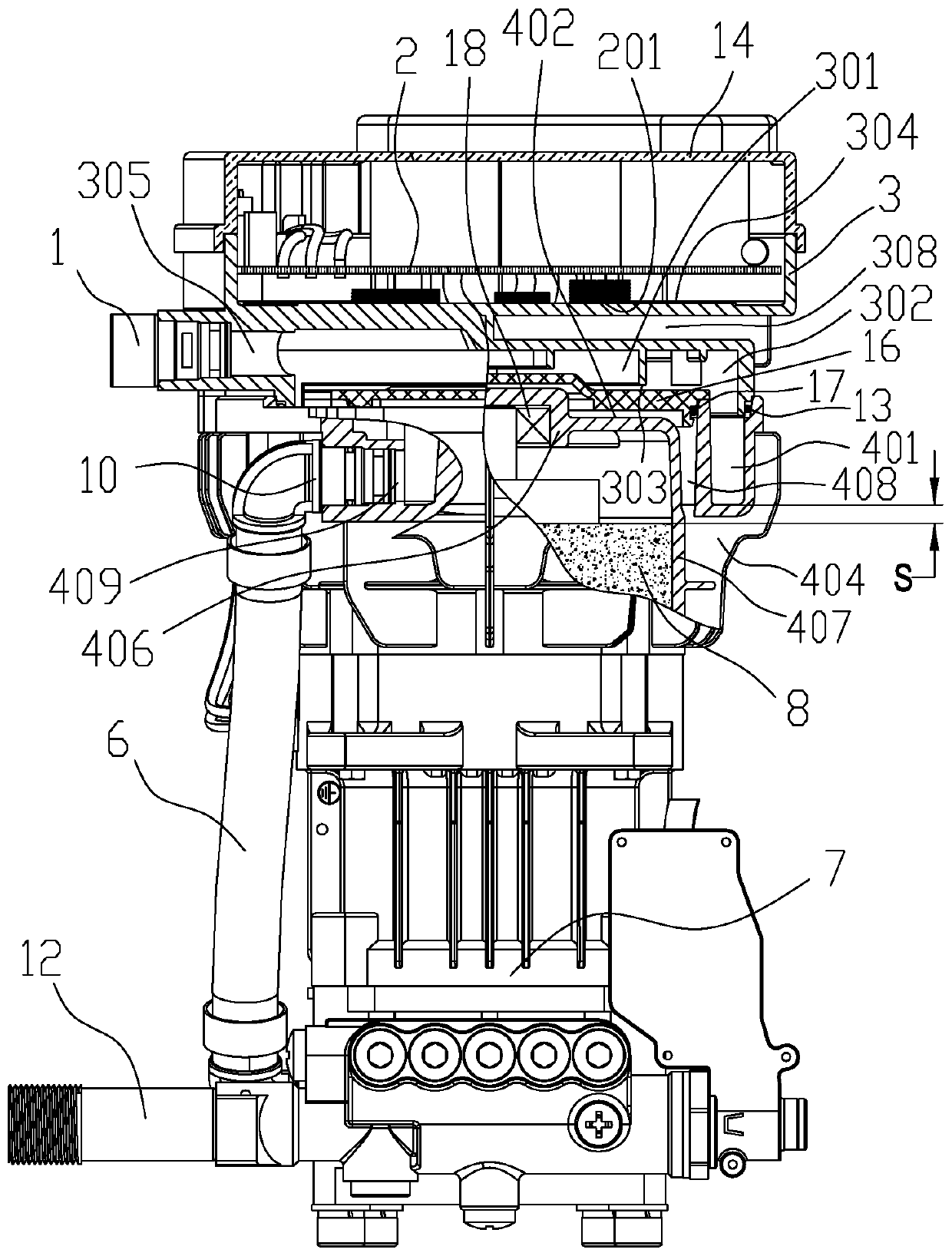

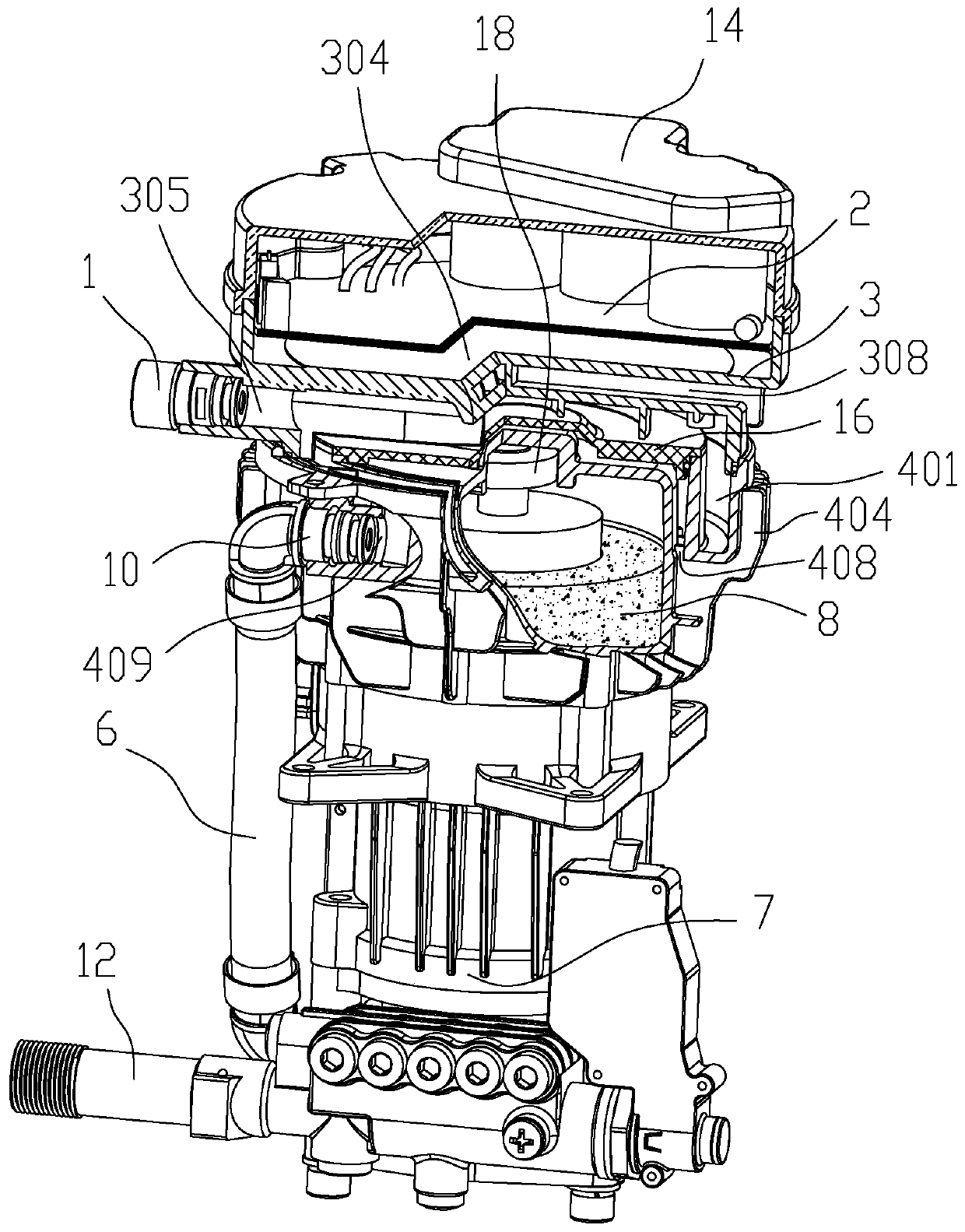

[0073] Such as Figures 1 to 4 As shown, a high-pressure cleaning device includes a spray gun unit and a motor pump unit. The motor pump unit 9 includes a pump 7 , a brushless motor and a controller water cooling body 3 . The brushless motor includes a brushless motor body 5 and a controller 2, and the controller 2 controls the operation of the brushless motor body 5. The brushless motor body 5 is a rare earth permanent magnet brushless motor, which includes an iron core 8 and a housing 4 for accommodating the iron core 8. As a typical motor type, a NdFeB permanent magnet brushless motor can be selected. The pump 7 has a pump water inlet 11 and a pump water outlet 12, and the pump water outlet 12 is connected to the spray gun unit through a water pipe to realize water spraying and cleaning. The casing 4 includes a receiving portion 407 and an annular cavity 401 formed on the receiving portion 407 along a circumference of the receiving portion 407 . The accommodating portion ...

Embodiment 2

[0094] Such as Figure 14 and 15 As shown, the difference from Embodiment 1 is that in this embodiment, at least one third heat-conducting rib 412 is provided between the annular cavity 401 and the receiving portion 407, and the annular cavity 401 passes through the third thermal-conducting rib 412 and the receiving portion 407. connected. The third heat-conducting rib 412 also plays a role of connecting and supporting the annular cavity 401 , so that heat can be quickly transferred to the annular cavity 401 to accelerate heat dissipation and cooling. Since the annular cavity 401 is provided with the third heat conduction rib 412 inside for heat conduction, there is no need to additionally provide the second heat conduction rib 404 , so the overall volume is relatively compact, the weight is light, and the cost is also low.

Embodiment 3

[0096] The difference from Embodiment 1 or 2 is that in this embodiment, the controller water-cooling body 3 is disposed outside the casing 4 in the circumferential direction, and is in sealing connection with the annular cavity 401 of the casing 4 through a seal.

[0097] In the present invention, the first heat conducting rib 306 , the second heat conducting rib 404 and the third heat conducting rib 412 not only serve as functional parts to realize heat conduction and external radiation, but also serve as structural parts to improve local strength. In the present invention, both the first sealing ring 13 and the second sealing ring 17 are "O" rings, which have good sealing performance and assemblability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com