Washing device for potato powder processing

A technology of cleaning device and potato flour, applied in application, food processing, climate change adaptation, etc., can solve the problems of heavy labor, reduced cleaning ability of brush rollers, affecting quality, etc., and achieve the effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

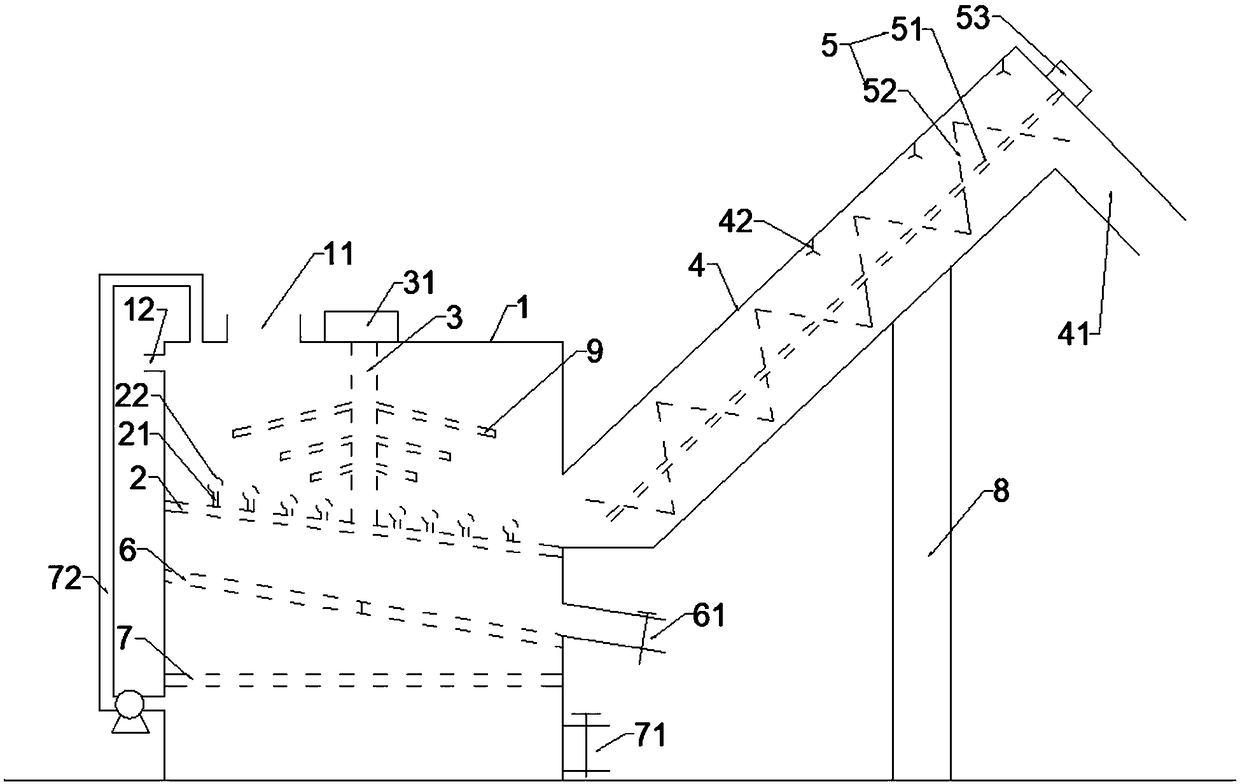

[0030] Such as figure 1 Shown, the invention provides a kind of cleaning device of potato flour processing, comprising:

[0031] Soaking tank 1, its top is provided with feed inlet 11, is provided with overflow outlet 12 on the side wall near the top; First pours appropriate amount of water from feed inlet 11, then pours potatoes into from feed inlet 11, pours The amount of potatoes is advisable to be completely submerged in water;

[0032] Vibrating screen 2, which is fixed on the inner side wall of the soaking tank 1 along the circumferential direction, the vibrating screen 2 divides the soaking tank 1 into an upper cavity and a lower cavity, the vibrating screen 2 is arranged obliquely, the vibrating The screen 2 is provided with a plurality of protruding rods 21 at inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com