Novel ammonia water evaporator

An evaporator and ammonia water technology, applied in evaporator accessories, spray evaporation, etc., can solve the problems that the mixing uniformity of ammonia gas and flue gas cannot be guaranteed, the mixing of ammonia gas and flue gas is uneven, and the maintenance and installation are complicated. The flange structure is simple to connect, easy to overhaul and check, and saves materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

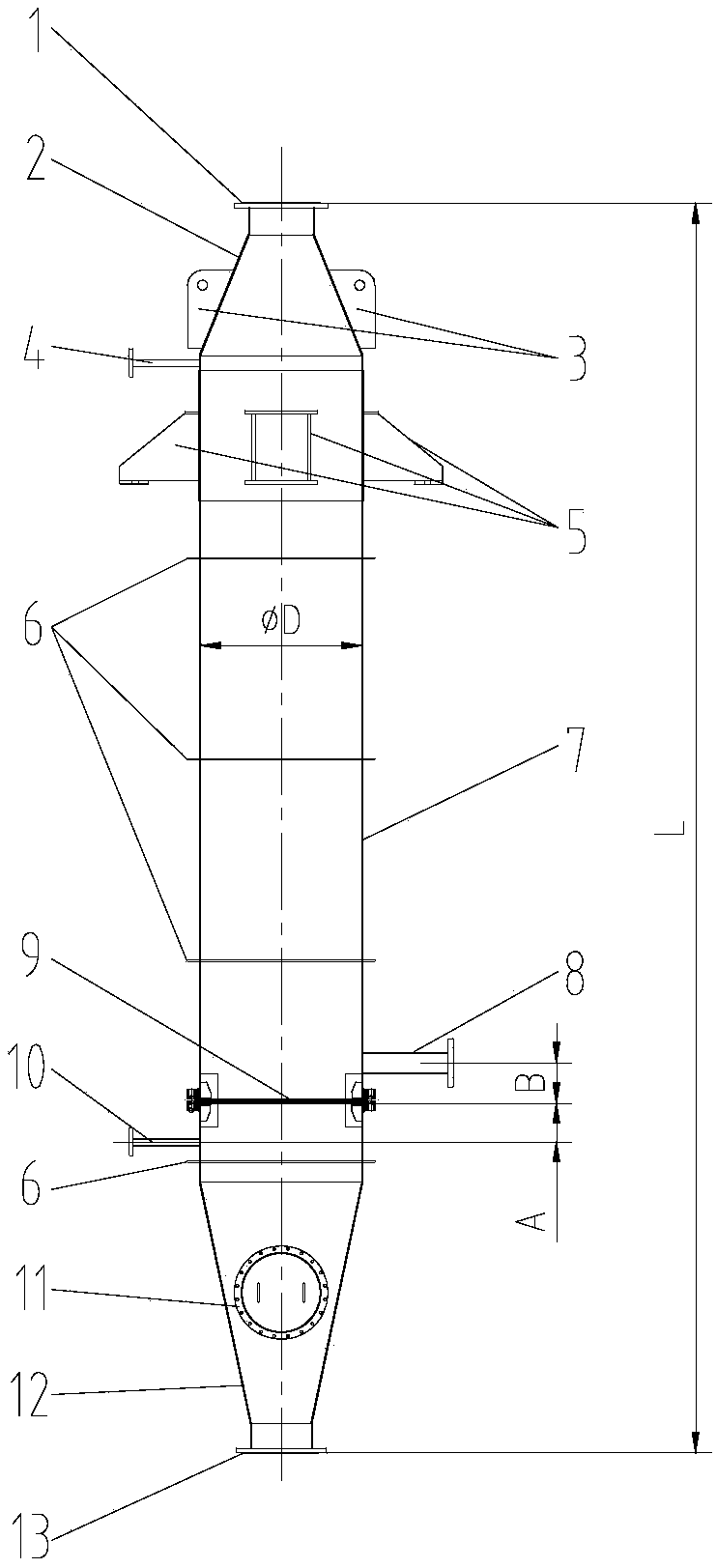

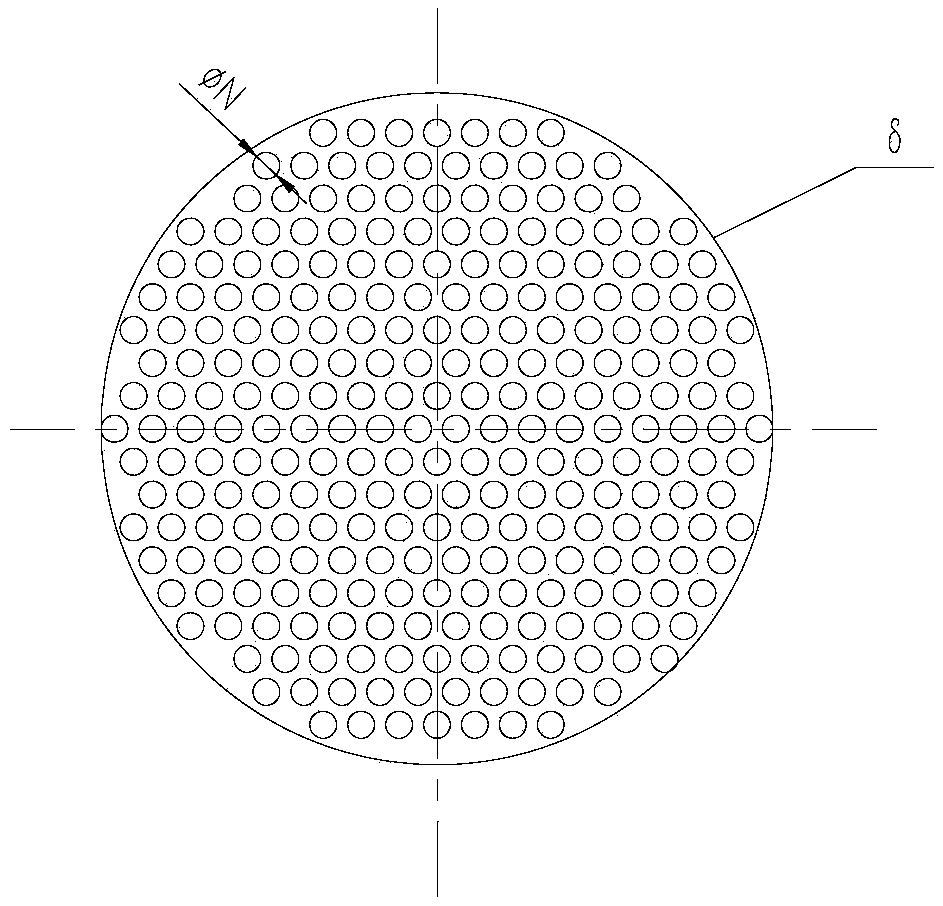

[0028] Embodiment 1 of the present invention: as figure 1 and figure 2 As shown, a novel ammonia water evaporator includes an outlet flange 1, an outlet variable diameter section 2, an evaporator body 7, an ammonia water spray gun opening 8, a uniform distribution plate 9, an inlet variable diameter section 12 and an inlet flange 13, wherein The top of the evaporator body 7 is provided with an outlet variable diameter section 2, the top of the outlet variable diameter section 2 is equipped with an outlet flange 1, and the bottom of the evaporator body 7 is provided with an inlet variable diameter section 12. The bottom of the inlet variable diameter section 12 is equipped with an inlet flange 13; the side of the lower part of the evaporator body 7 close to the inlet variable diameter section 12 is provided with an ammonia water spray gun opening 8, and the inner wall of the evaporator body 7 is fixedly installed with uniform plate 9, and the vertical installation height of t...

Embodiment 2

[0029] Embodiment 2: as figure 1 and figure 2 As shown, a novel ammonia water evaporator includes an outlet flange 1, an outlet variable diameter section 2, an evaporator body 7, an ammonia water spray gun opening 8, a uniform distribution plate 9, an inlet variable diameter section 12 and an inlet flange 13, wherein The top of the evaporator body 7 is provided with an outlet variable diameter section 2, the top of the outlet variable diameter section 2 is equipped with an outlet flange 1, and the bottom of the evaporator body 7 is provided with an inlet variable diameter section 12. The bottom of the inlet variable diameter section 12 is equipped with an inlet flange 13; the side of the lower part of the evaporator body 7 close to the inlet variable diameter section 12 is provided with an ammonia water spray gun opening 8, and the inner wall of the evaporator body 7 is fixedly installed with uniform plate 9, and the vertical installation height of the evenly distributed pla...

Embodiment 3

[0030] Embodiment 3: as figure 1 and figure 2 As shown, a novel ammonia water evaporator includes an outlet flange 1, an outlet variable diameter section 2, an evaporator body 7, an ammonia water spray gun opening 8, a uniform distribution plate 9, an inlet variable diameter section 12 and an inlet flange 13, wherein The top of the evaporator body 7 is provided with an outlet variable diameter section 2, the top of the outlet variable diameter section 2 is equipped with an outlet flange 1, and the bottom of the evaporator body 7 is provided with an inlet variable diameter section 12. The bottom of the inlet variable diameter section 12 is equipped with an inlet flange 13; the side of the lower part of the evaporator body 7 close to the inlet variable diameter section 12 is provided with an ammonia water spray gun opening 8, and the inner wall of the evaporator body 7 is fixedly installed with uniform plate 9, and the vertical installation height of the evenly distributed pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com