Dust remover capable of realizing intelligent discharging

A dust collector, intelligent technology, applied in the direction of chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems that maintenance personnel cannot judge the damage location, increase maintenance difficulty and time, reduce dust removal effect, etc., and achieve improved dust removal The effect of saving maintenance time and reducing the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

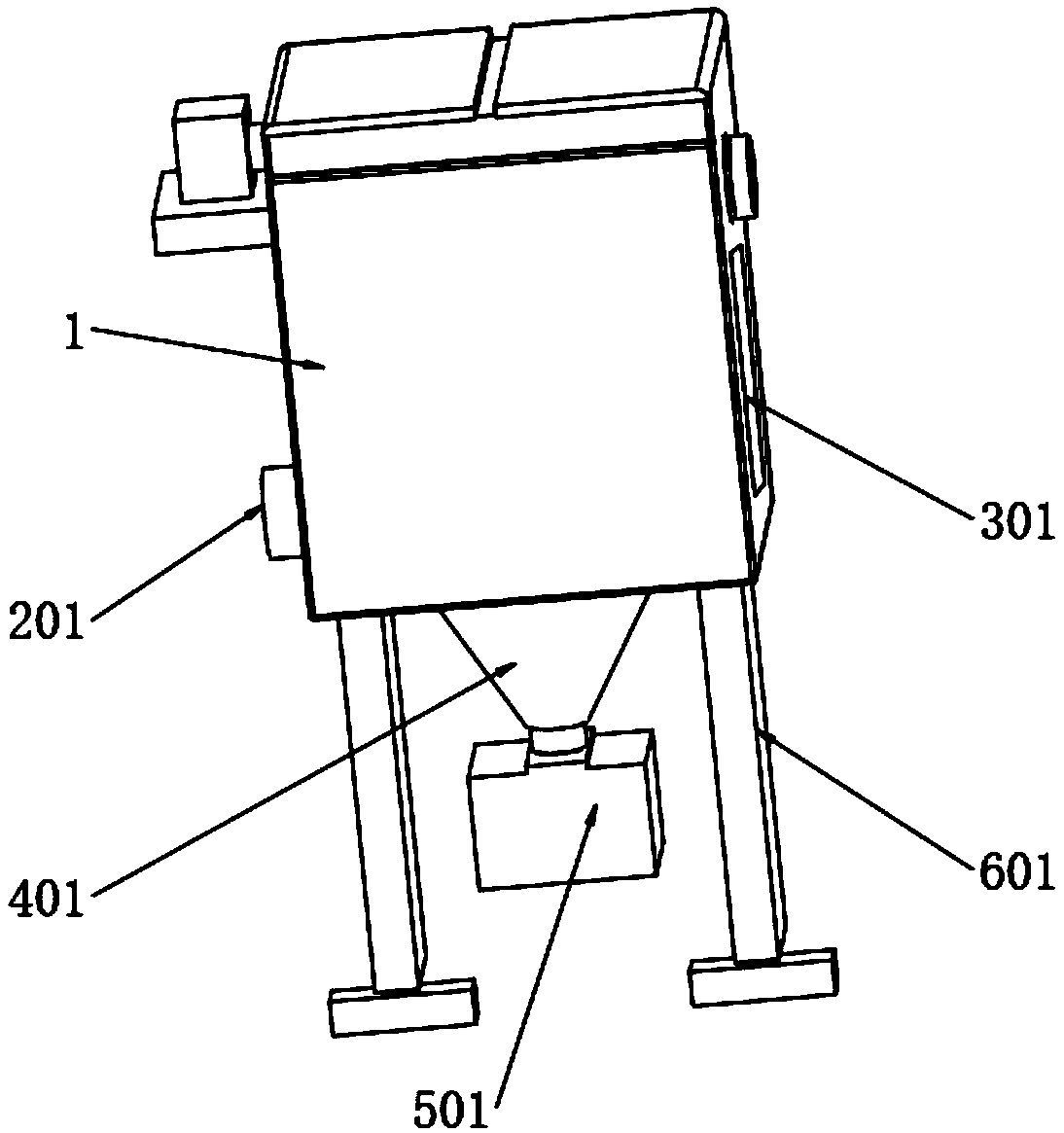

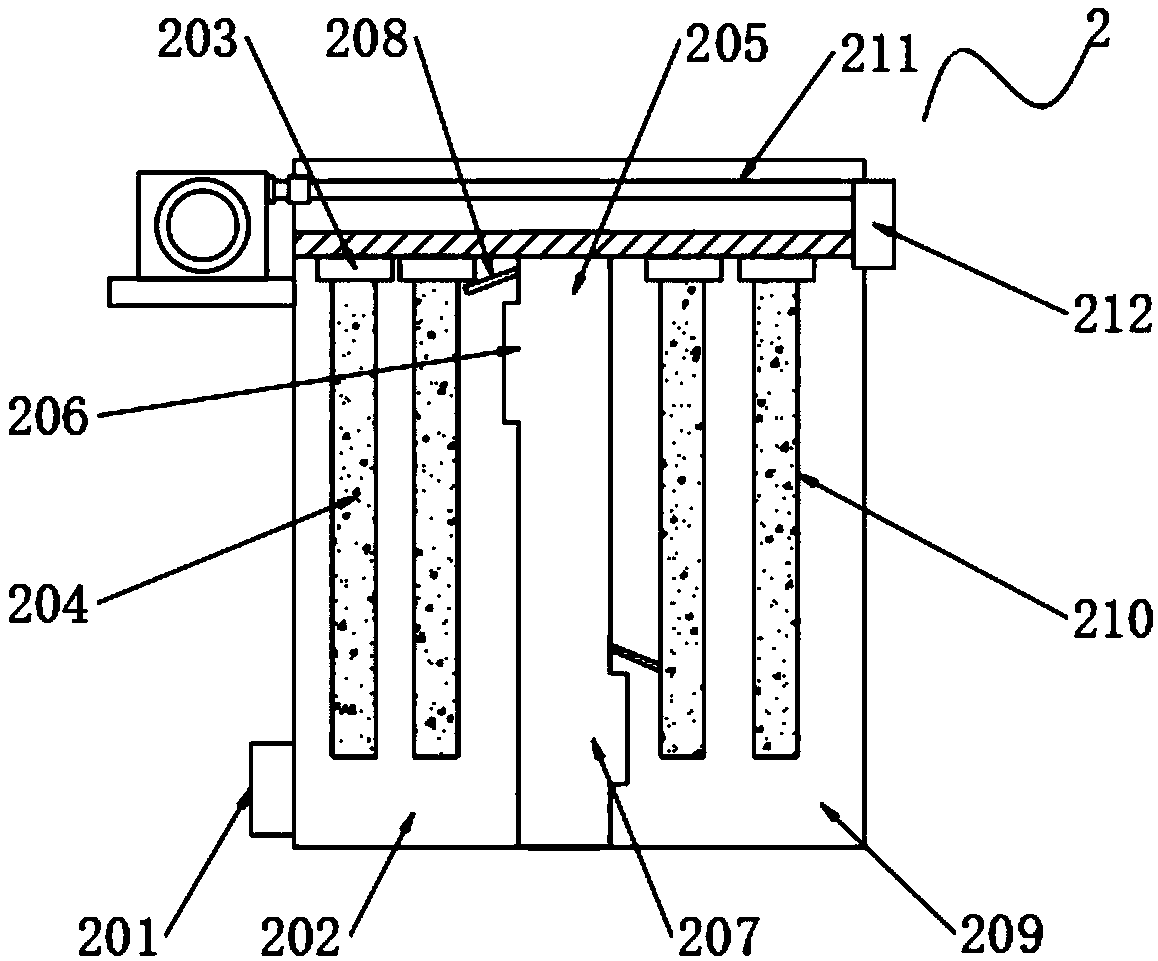

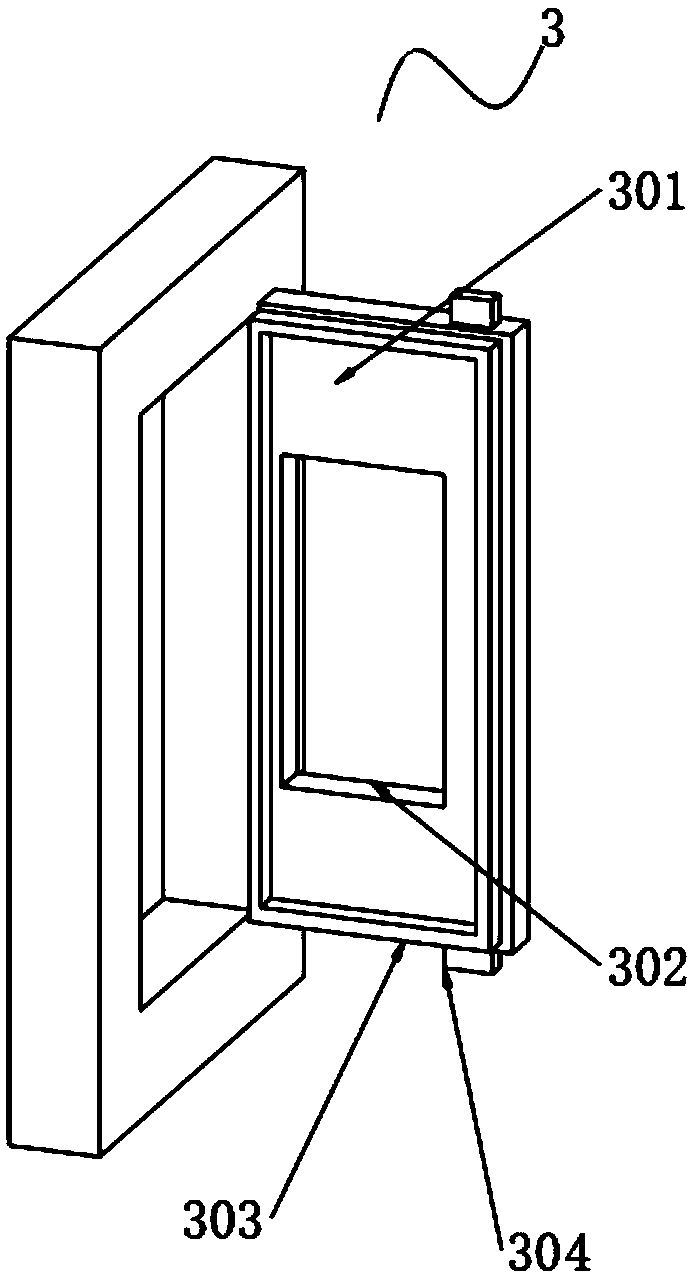

[0030] Example: such as Figure 1-6As shown, the present invention provides a technical solution, a dust collector capable of intelligent blanking, including a dust removal box 1, a dust removal assembly 2 is installed inside the dust removal box 1, and the dust removal assembly 2 includes an air inlet pipe 201, a first dust removal chamber 202 , Venturi tube 203, first dust filter bag 204, connecting channel 205, air inlet 206, air outlet 207, air deflector 208, second dust chamber 209, second dust filter bag 210, compressed air pipe 211 and exhaust Air duct 212, the lower end of one side of the dust removal box 1 is equipped with an air inlet pipe 201, the side of the air inlet pipe 201 is installed with a first dust removal chamber 202, and the top of the first dust removal chamber 202 is equipped with a Venturi tube 203, and the Venturi tube The first dust removal filter bag 204 is installed on the outside of 203, and a connecting channel 205 is installed on one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com