Surface paint spraying device for automobile parts processing

A technology for auto parts and painting equipment, which is applied in painting booths, pretreatment surfaces, and devices for coating liquids on surfaces. The effect of uniform, uniform coverage and convenient processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

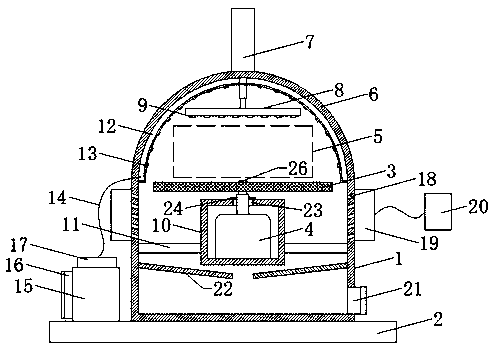

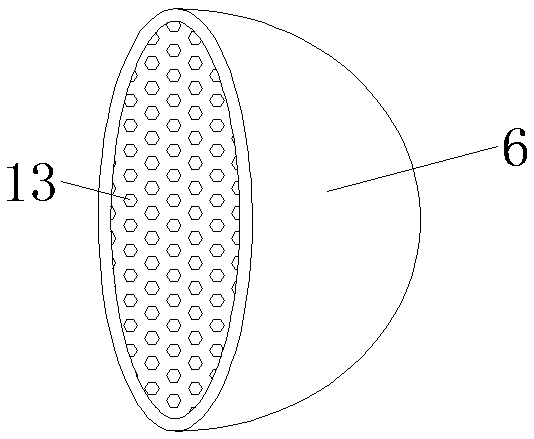

[0018] Please refer to the figure, in the embodiment of the present invention, a kind of surface painting equipment for the processing of auto parts includes a housing 1, a base 2, a placement screen 3, a motor 4 and a sealing door 5; the housing 1 is fixedly mounted on the base 2, the housing 1 is a cylindrical structure, the motor 4 is vertically arranged in the housing 1, and the central axis of the motor 4 coincides with the central axis of the housing 1, and the outer side of the motor 4 is provided with a sealing cover 10, which is sealed Both sides of the cover 10 are fixed on the inner wall of the housing 1 by the support rod 11, the output shaft of the motor 4 rotates through the sealing cover 10 through the bearing 23, and a sealing bush 24 is fixed on the outer end of the bearing 23 to keep the inner seal, To prevent paint from entering the sealing cover 10, the output shaft of the motor 4 is provided with a horizontal placement screen 3 that follows its rotation, an...

Embodiment 2

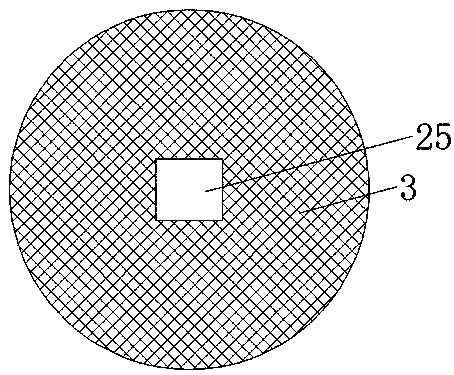

[0023] On the basis of Embodiment 1, the said placement screen 3 is detachably connected to the output shaft of the motor 4, and the output shaft of the motor 4 is coaxially fixed with a vertical rectangular mounting rod 26, placed on the center of the placement screen 3 A rectangular hole 25 having the same shape as the rectangular mounting rod 26 is provided, so that the rectangular mounting rod 26 can pass through the rectangular hole 25, and the placing net plate 3 is installed on the output shaft of the motor 4, so that the placing net plate 3 follows the motor 4 to rotate, When it is necessary to take off the placement screen 3, it can be disengaged only by moving the placement screen 3 upwards, which makes the replacement of the placement screen 3 more convenient and quick, and avoids the paint clogging the mesh caused by long-term use.

[0024] By opening the airtight door 5, the auto parts that need to be painted are placed on the placed screen 3. When painting is requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com