Metal bearing cleaning method

A technology for cleaning bearings and hardware, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, increased labor intensity, and inability to effectively clean, and achieve a cleaning volume Large, high structural stability, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

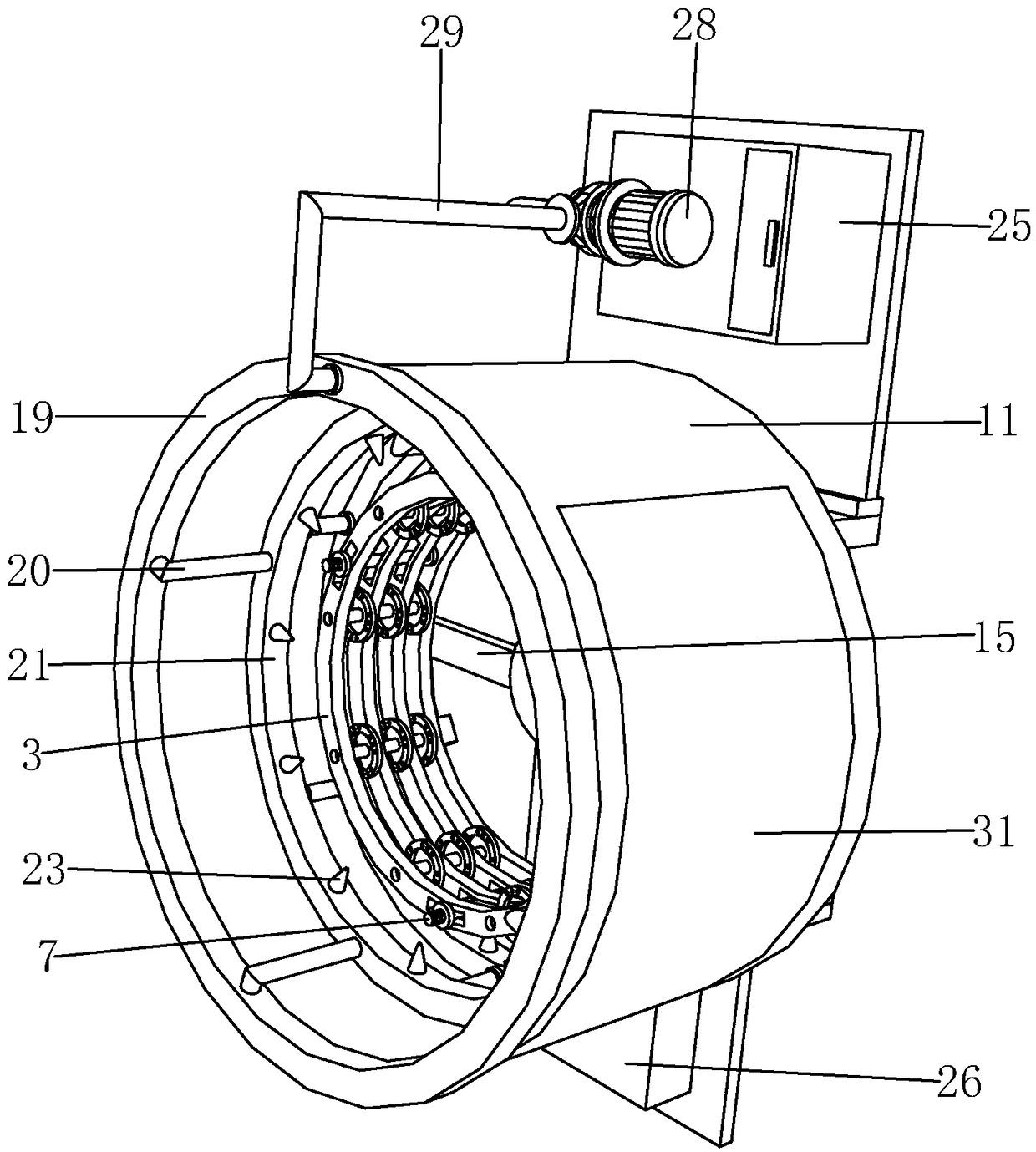

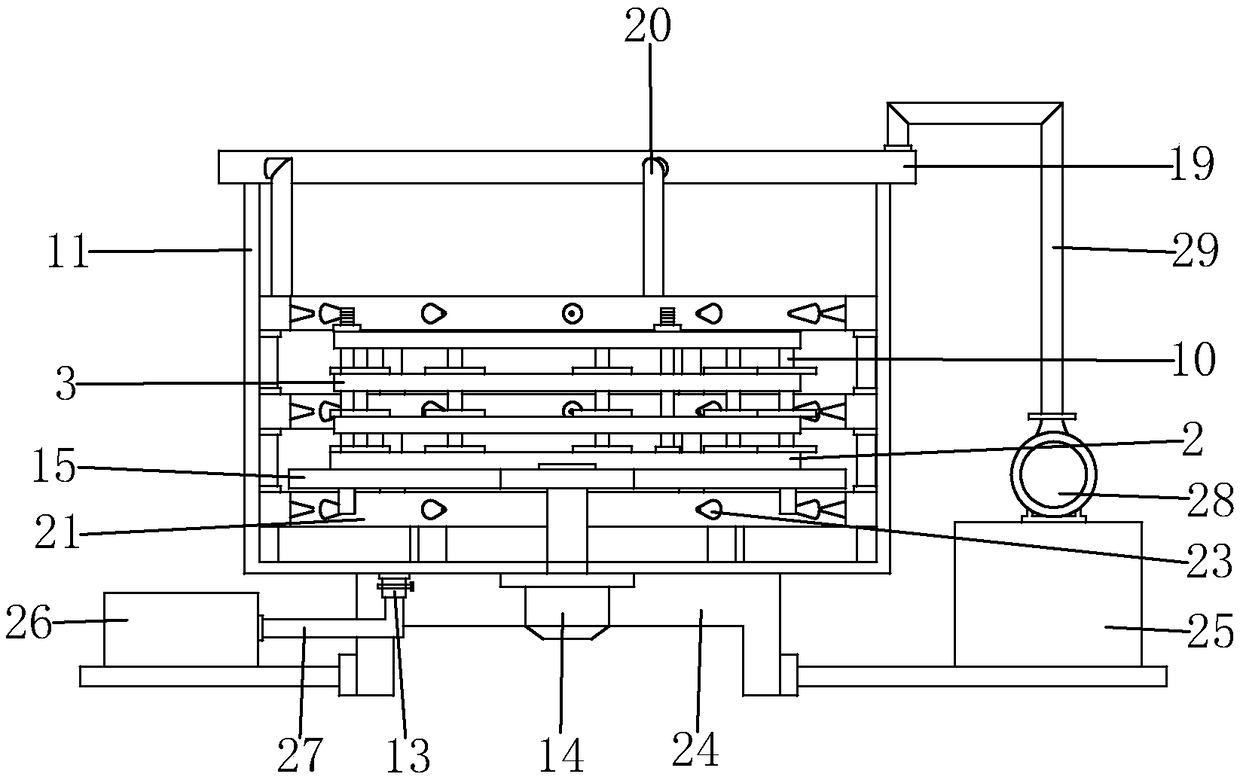

[0030] Such as Figure 1 to Figure 5 Shown, be a kind of hardware bearing cleaning method of the present invention, comprise the steps:

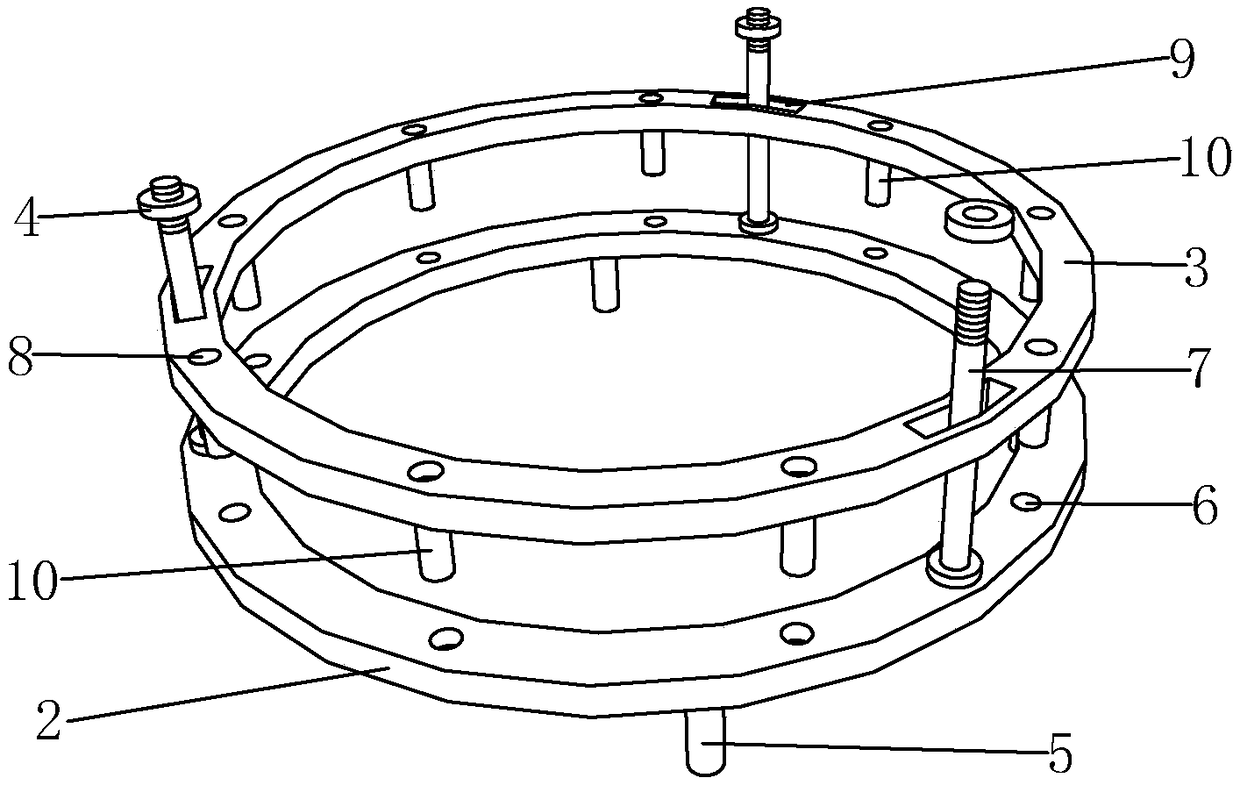

[0031](a) Cleaning frame assembly: cleaning frame 1 includes support bottom ring 2, shelving ring 3 and lock cap 4, and the bottom surface of support bottom ring 2 is provided with fixing column 5, and support bottom ring 2 is surrounded by distribution of limited holes 6 and installation Column 7, positioning holes 8 and arc-shaped through grooves 9 are distributed around the resting ring 3, fixed pins 10 are arranged on the bottom surface of the resting ring 3, and the limiting holes 6 and positioning holes 8 correspond to the fixing pins 10 respectively. 7 passes through the arc-shaped through groove 9, the lock cap 4 is threadedly connected to the top of the mounting column 7, the lock cap 4 presses the surface of the rest ring 3, the cleaning rack 1 is easy to disassemble and easy to replace if damaged, it can be stacked up and down, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com