Machining device used for producing gas input pipeline of integration stove

An air intake duct and processing device technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve problems such as short service life and poor sealing performance, and achieve improved accuracy and stability, improved stability, Easy to install and remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

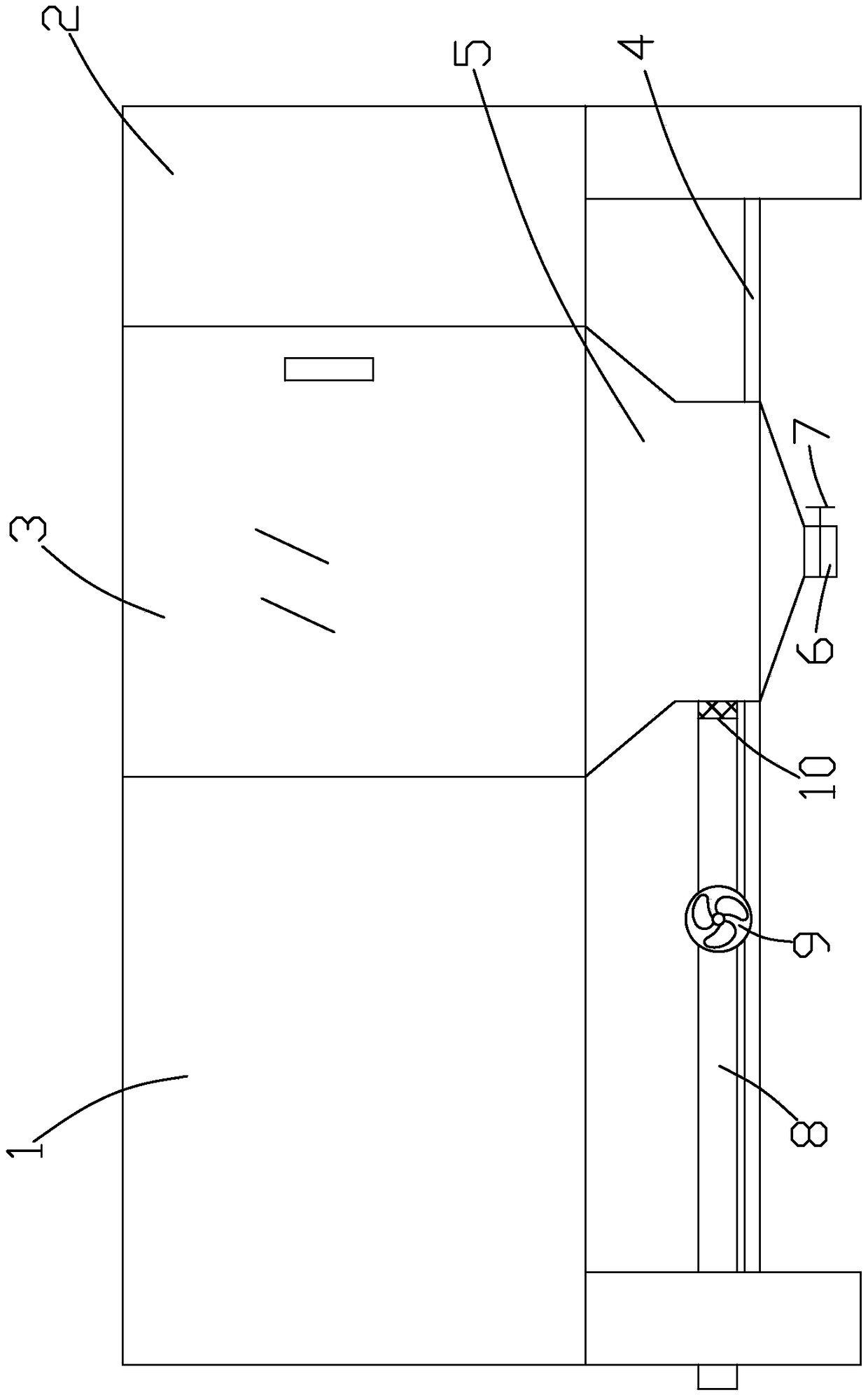

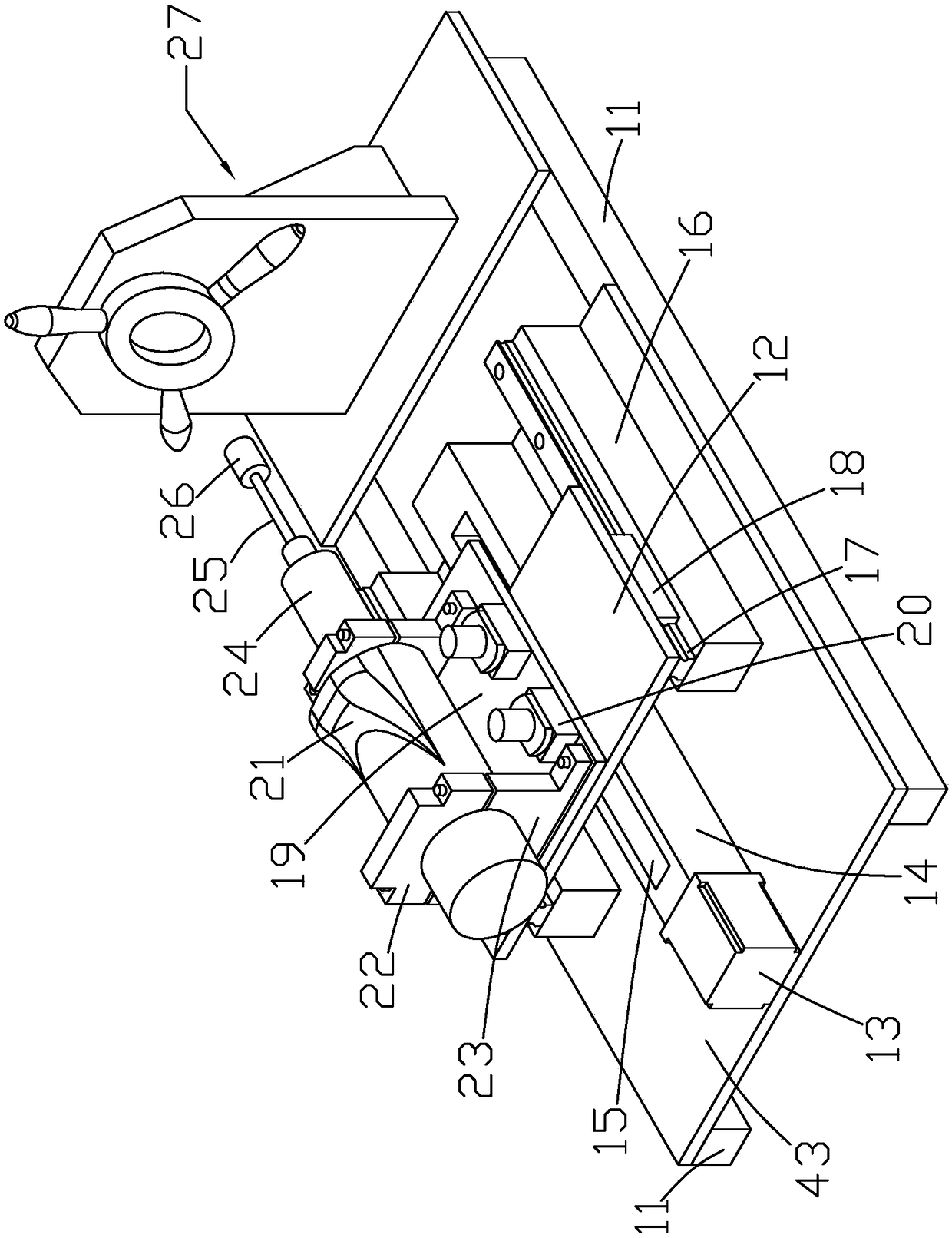

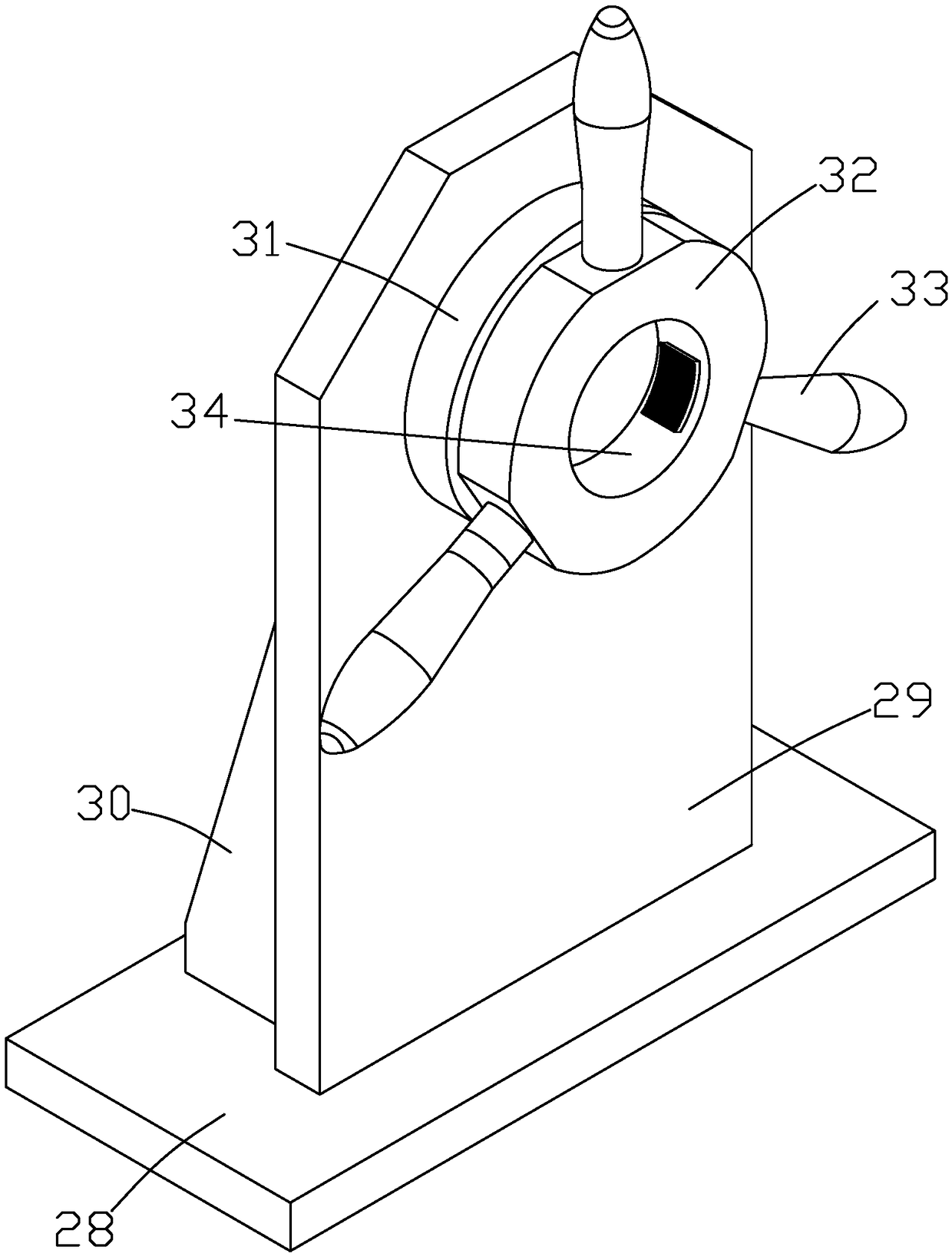

[0029] Such as Figure 1 to Figure 5As shown, it is a processing device for producing the air intake duct of an integrated stove according to the present invention, which includes a first box body 1 and a second box body 2, and a sliding door is arranged between the first box body 1 and the second box body 2 3. There are two first support bars 11 arranged in parallel between the first box body 1 and the second box body 2, and a drilling mechanism is arranged in the first box body 1, and the drilling mechanism is fixedly connected to the two first support bars 1 1, the drilling mechanism includes a second support plate 43, a horizontal moving plate 12 and a first support plate 19, the second support plate 43 is fixedly connected to the top surfaces of the two first support bars 11, and the second support plate 43 A moving mechanism and two second support bars 16 are arranged on the top surface of the top, the moving mechanism is located at the center of the two second support b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com