Safety protection system and method for end-line shunting operation of power plant dumper

A technology of safety protection and dumper, which is applied in the direction of railway signal and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

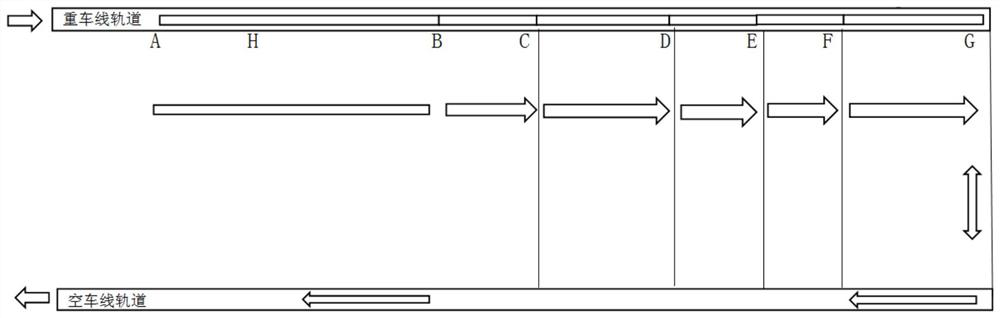

[0043] figure 1 It is the layout plan of the site section of the "heavy train line" of the dumper in the power plant. A single dumper is divided into two tracks, the parallel heavy train line and the empty train track. The arrow indicates the direction of locomotive travel.

[0044] Heavy vehicle line: 10 vehicle points (A point), 5 vehicle points (H point), 3 vehicle points (B point), 1 vehicle point (C point), secondary alignment area (CD area), heavy vehicle traction area (DE area), dumper coal unloading area (EF area);

[0045] Empty car line: each empty car is moved to the empty car line through the empty car translation area (FG area). The empty cars are grouped into a row after manual cleaning of coal, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com