Cable-free high-density cubesat and assembly method thereof

A high-density, cube-sat technology, applied in the field of satellites, can solve problems such as insufficient openness of testers, restrictions on satellite layout forms, and inconvenient installation and debugging, so as to shorten the debugging and development cycle, realize high-density integration, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

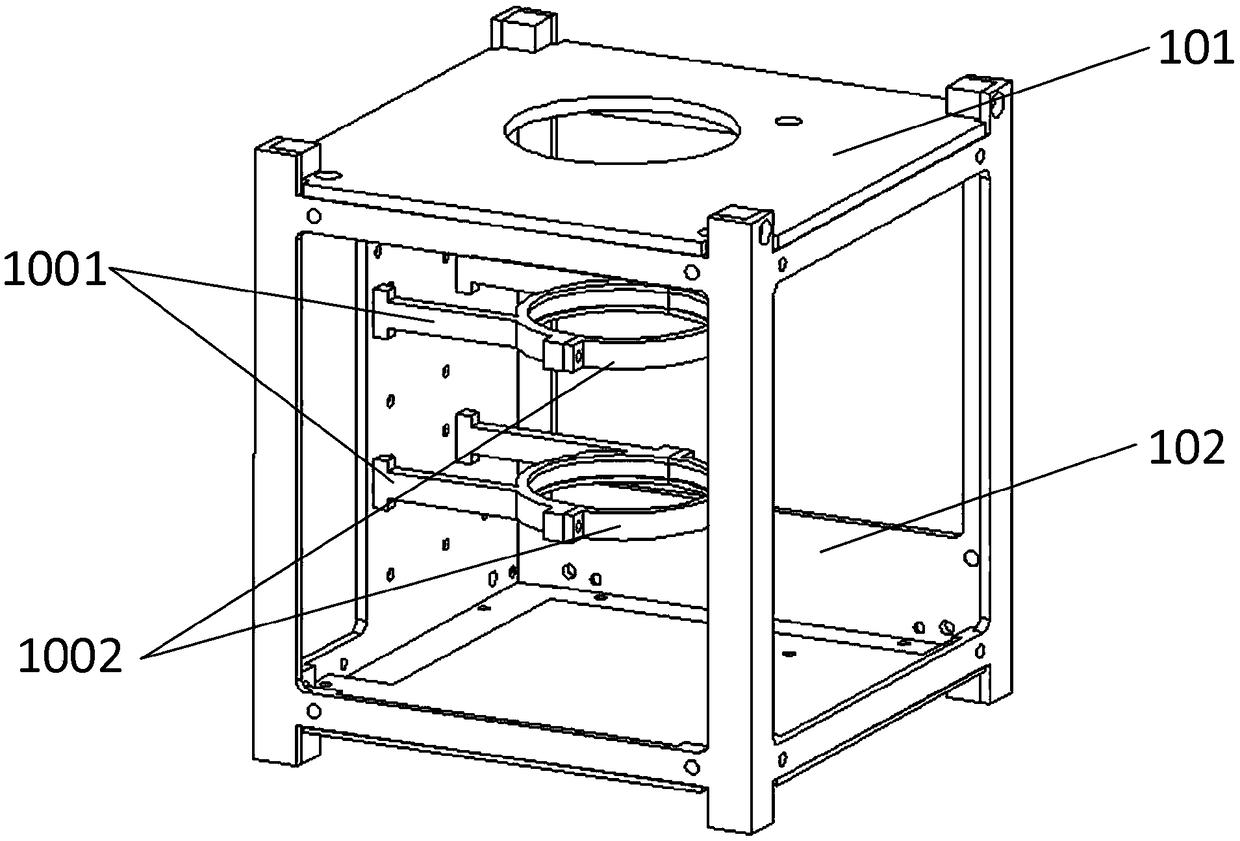

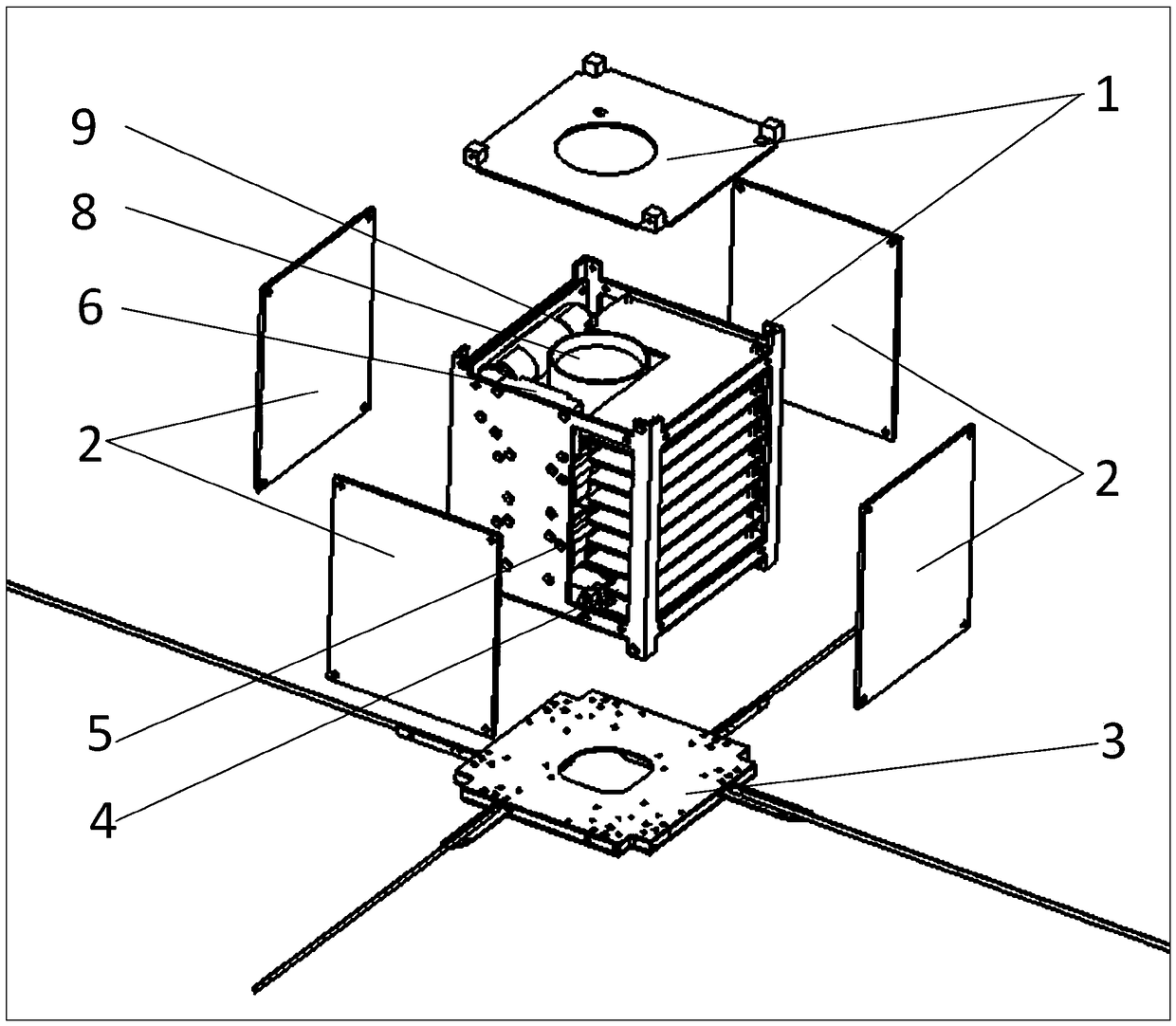

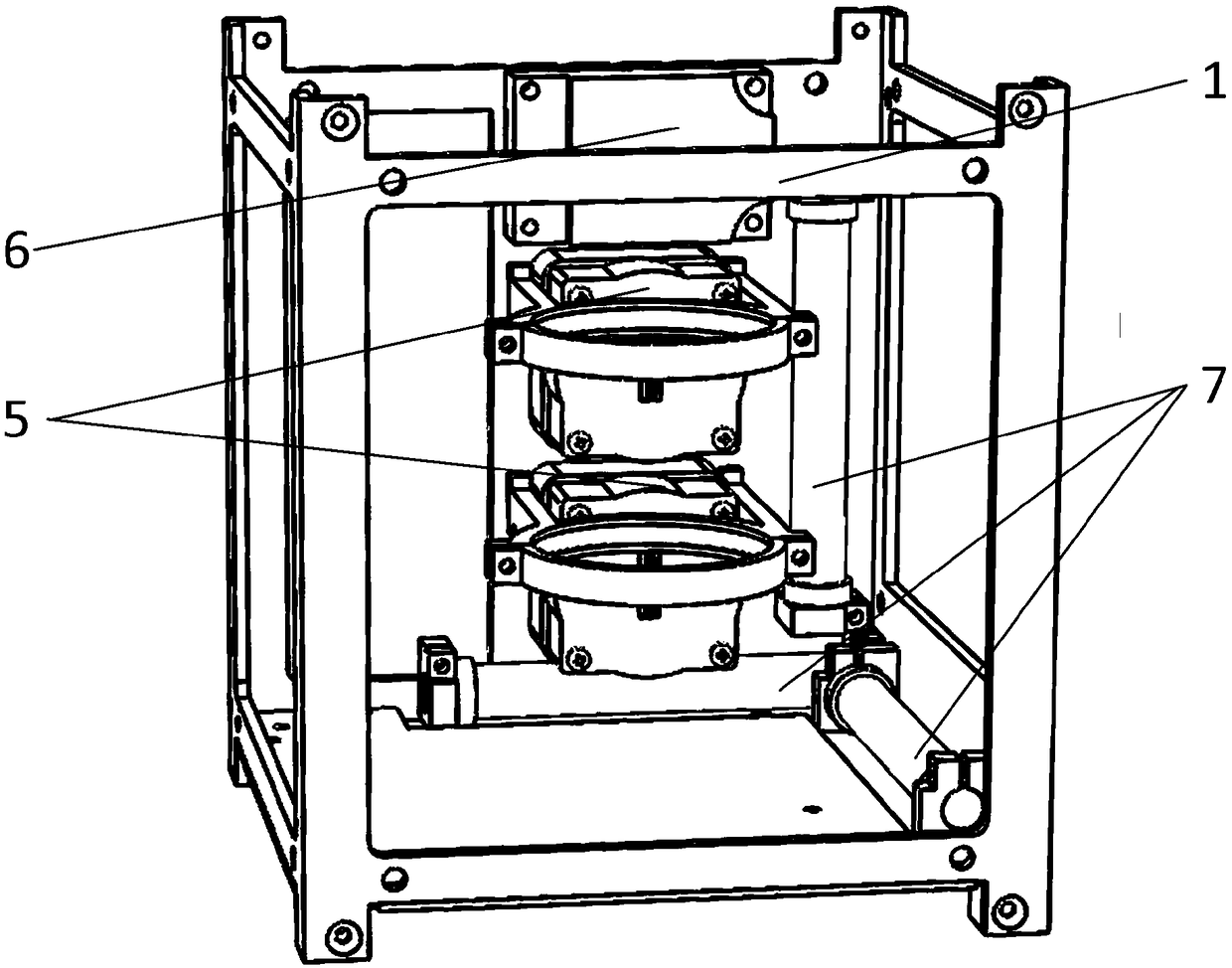

[0032] The present invention firstly complies with the size requirements of the one-unit cube star standard, and integrates the standard one-unit cube star structure. CubeSat integrated electronic system design integrates the advantages of flexible circuit boards and traditional printed circuit boards, integrates the systems on the star into one circuit board, weakens the boundaries of the subsystems on the circuit board, shares the resources on the star, and integrates the electronics of the whole star. Highly integrated, realizing the integrated electronic integration on the star and the cable-free connection between various systems. Using additive manufacturing technology to process complex mechanical structures, no longer sticking to the idea that the existing satellite platform and the payload part are independent in space, centering on the remote sensing camera on board, the entire circuit board is folded around the payload in an orderly manner, The integrated design of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com