Fodder baler with packaging bag sealing device

A sealing device and packaging bag technology, applied in packaging sealing/fastening, packaging, transportation packaging and other directions, can solve the problems of low feed packaging efficiency, avoid feed waste and loss, increase production, and prevent feed spillage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

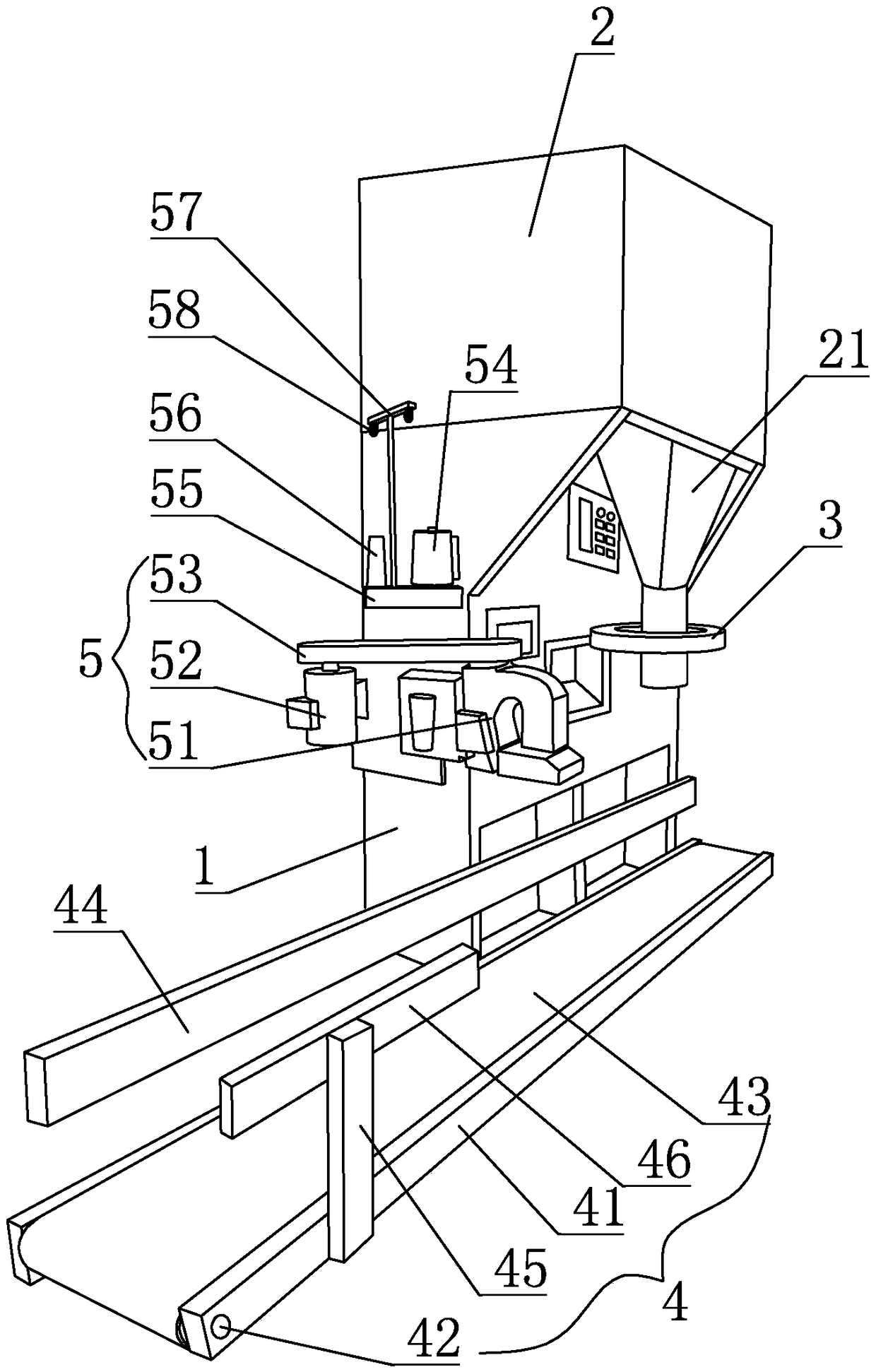

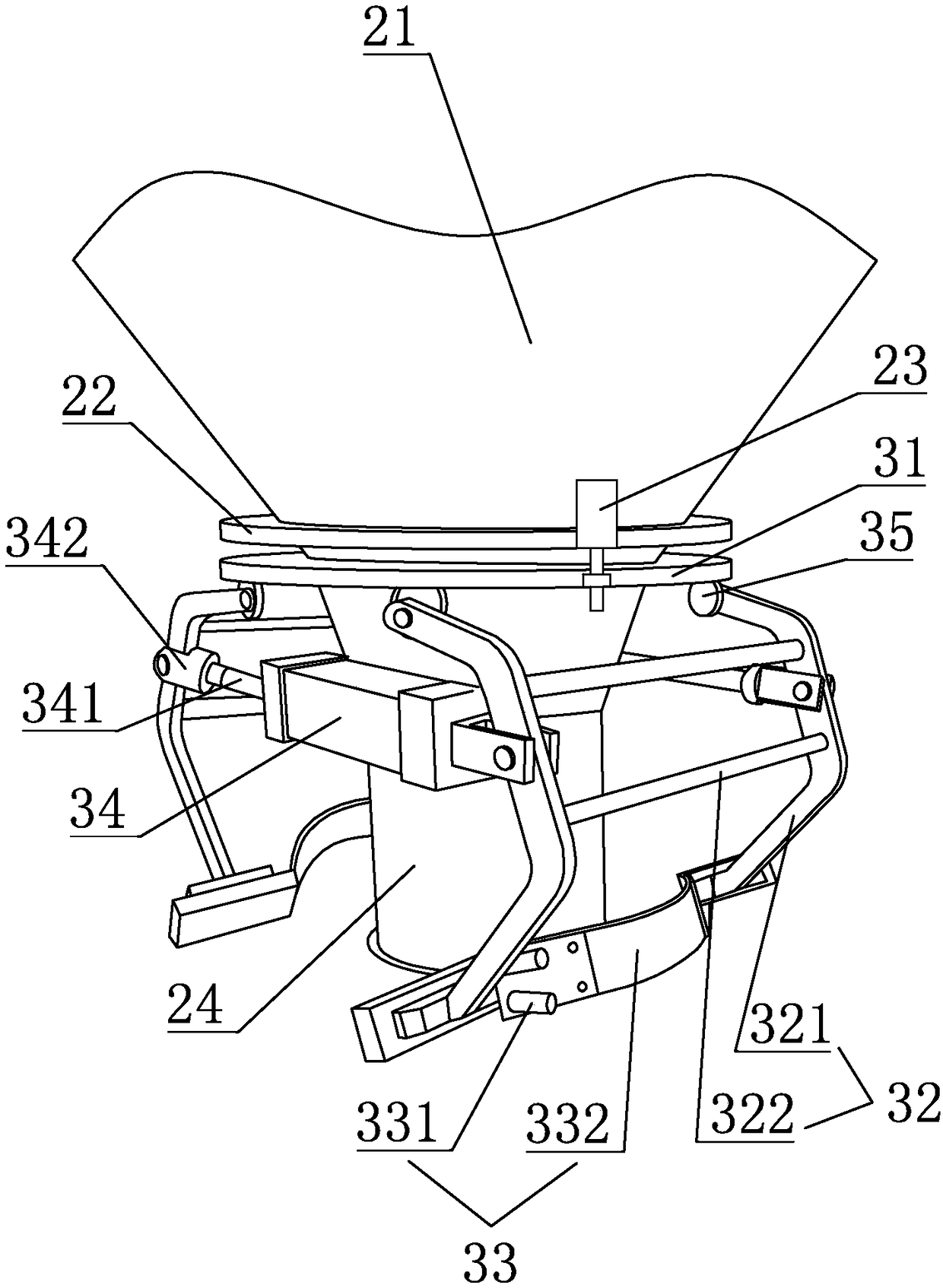

[0014] refer to Figures 1 to 2 , a kind of feed packer with packing bag sealing device of the present invention, comprises machine body 1, the feed bin 2 that is arranged on the top and control system, the bottom of described feed bin 2 is provided with the conical discharge hopper that is placed on the front side of body 1 21. The lower part of the conical discharge hopper 21 is fixed with a positioning ring 22, and the positioning ring 22 is suspended with a discharge guide cylinder 24 and a pneumatic bag clamp through at least three load cells 23 uniformly arranged along a circle of the positioning ring 22. 3. The upper end of the discharge guide cylinder 24 is set in a funnel shape and is movably connected to the lower end of the conical discharge hopper 21. The lower part of the conical discharge hopper 21 is also provided with a discharge valve. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com