Steel bar coil shaping machine

A shaping machine and steel bar technology, which is applied in the field of steel rolling, can solve the problems of steel bar coils not being shaped and affecting the efficiency of baler binding work, so as to improve the appearance quality, improve the appearance of coils, and reduce the chance of baler chaotic lines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

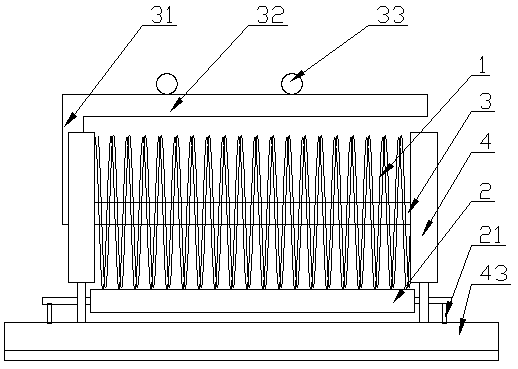

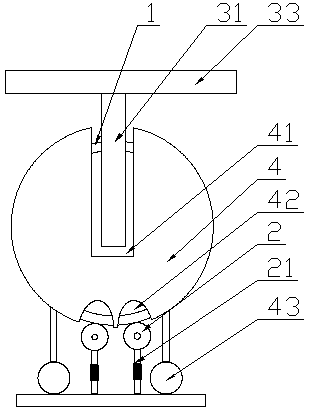

[0024] The present embodiment provides a steel bar coil shaping machine, such as Figure 1-2 As shown, it includes a plastic rod 2 driven by a motor and adjustable in height. A hanging rod 3 for placing a steel bar 1 is arranged on the top of the plastic rod 2 . To extrude the extruded plate 4 of the steel bar 1.

[0025] When the steel bar coil shaping machine in the present application is used, the steel bar 1 coil is first transferred to the hanging rod 3, and then the hanging rod 3 is moved to the top of the shaping roller by the guide rail 33 or other moving devices, and the steel bar 1 coil at this time is The roll is still relatively loose, so the extruded plates 4 at both ends can be made close to each other, and the steel bar 1 can be coiled slightly tightly, and then the height of the shaping stick 2 can be adjusted to lift the steel bar 1 coil, and then the steel bar 1 coil can be rolled under gravity. Together with the rotation of the shaping rod 2, the coiling of...

Embodiment 2

[0027] In this embodiment, on the basis of the embodiment 1, it is further defined that: a telescopic rod for supporting the shaping roller 2 and adjusting the height of the shaping roller 2 is arranged under the shaping roller 2 . The telescopic rod has a simple structure and is easy to use, and there are various types on the market, and the substitutability is strong.

Embodiment 3

[0029] On the basis of Embodiment 1, this embodiment further defines: it further includes a slide rail 43 arranged along the installation direction of the shaping stick 2 , and the extruding plate 4 can slide on the slide rail 43 through pulleys. The slide rail 43 can well limit the moving direction of the extruded plate 4, so as to better shape the coil of the steel bar 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com