An optical fiber preform horizontal transport device

A technology of optical fiber preform and handling device, which is applied in the direction of transportation and packaging, mechanical conveyors, conveyor objects, etc., which can solve the problems of inconvenient operation, time-consuming and labor-intensive operations, hidden dangers of personnel and workpiece damage, etc. Good loading status, safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

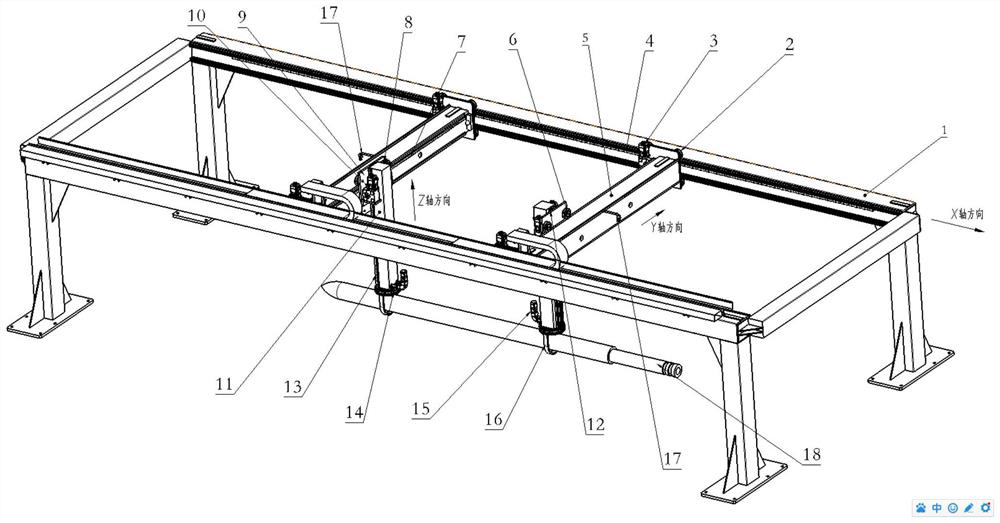

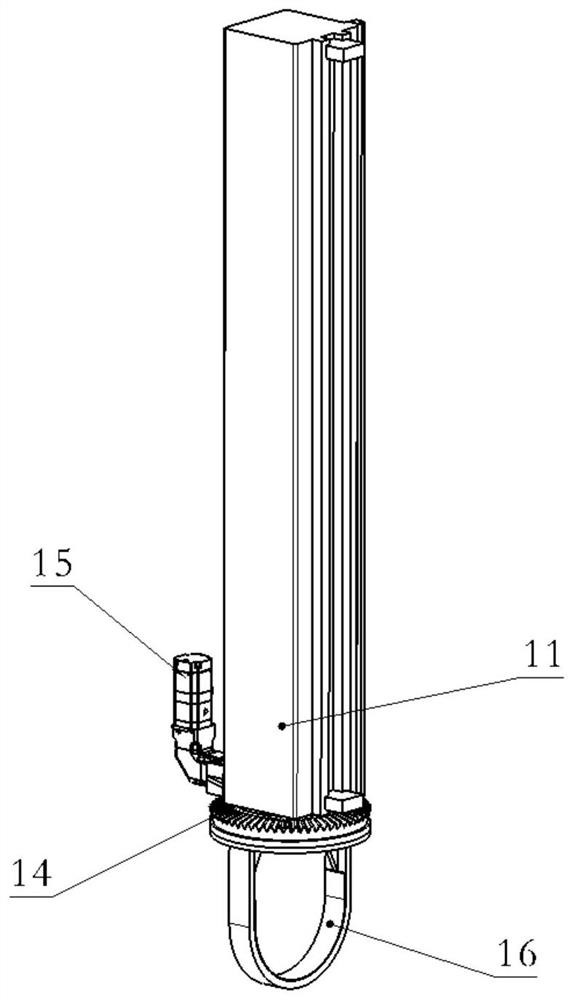

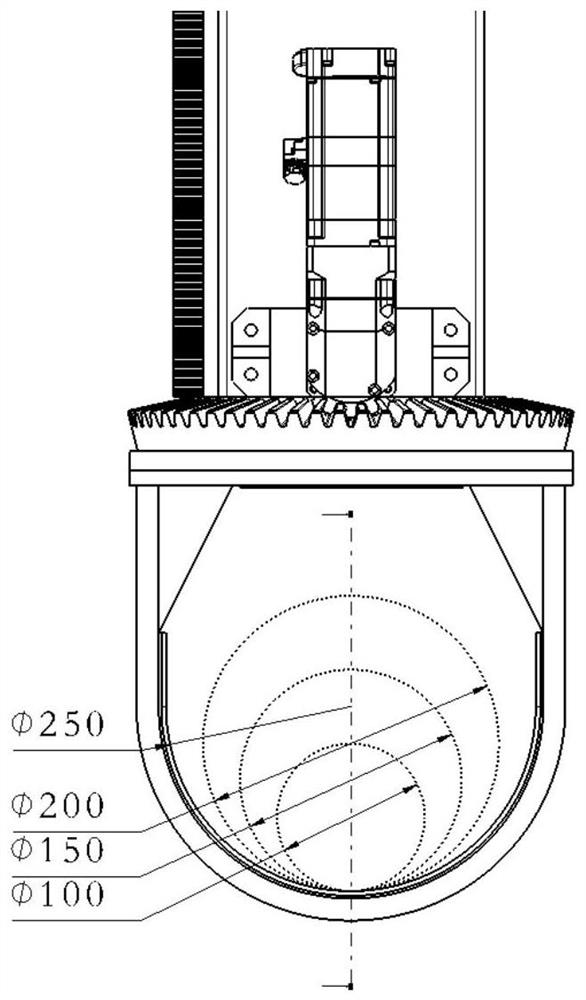

[0021] Including a truss 1, the truss is a frame truss, including an upper frame and columns at both ends, a longitudinal guide rail is installed above the truss, and two longitudinal rail cars are straddled on the longitudinal rail, and the longitudinal rail cars include There is a beam 5, the two ends of the beam are equipped with longitudinal rollers 2 configured with the longitudinal guide rails, and the two ends of the beam are provided with a longitudinal driving mechanism, and the longitudinal driving mechanism includes a rack and pinion mechanism 4 and a gear Connected drive motor 3. The wale drive mechanism drives the beam to run along the longitudinal direction of the truss (X-axis direction). A transverse movable seat is installed on each longitudinal rail car, and the described transverse movable seat includes a movable seat 9 and a transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com