Take-up machine

A technology of a wire take-up machine and a wire take-up device is applied in the field of wire take-up machines, which can solve problems such as troublesome disk change, skewed placement, and potential safety hazards, and achieve the effect of ensuring the wire-receiving process, preventing wire breakage, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments.

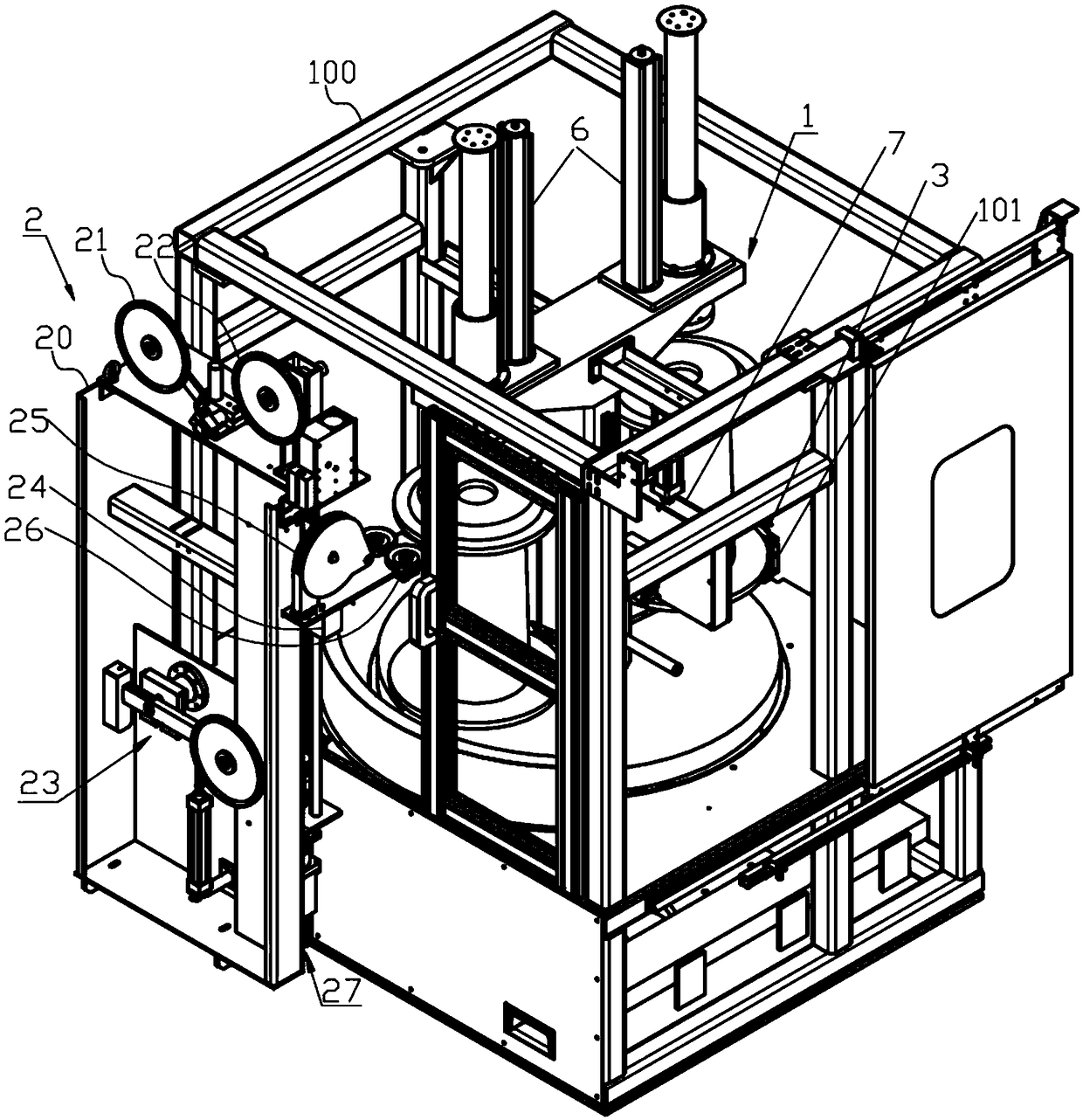

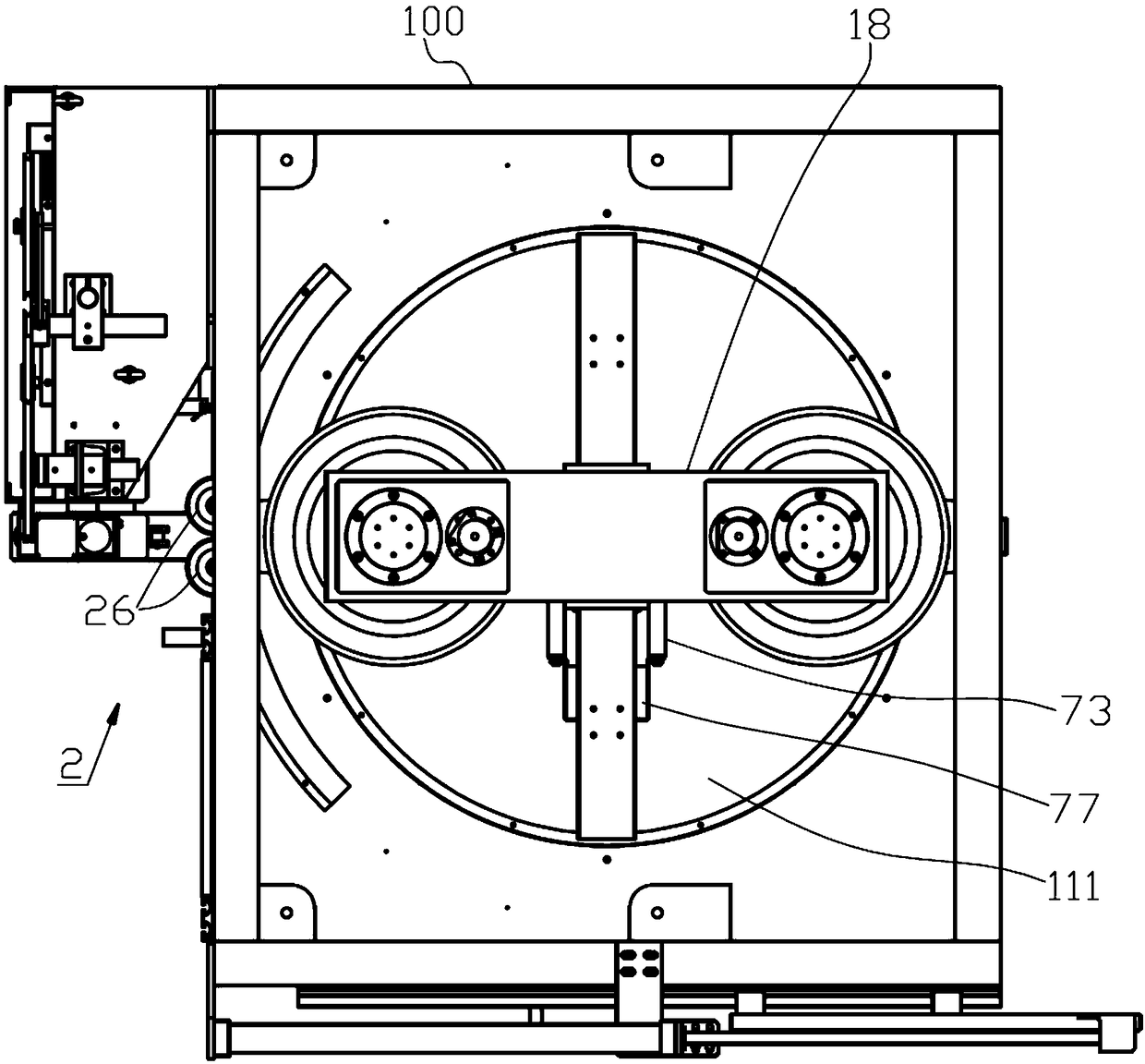

[0037] like figure 1As shown, a wire take-up machine according to an embodiment of the present invention includes a frame 100 , a turntable type wire take-up device 1 , and a wire support 2 disposed on the side of the frame 100 .

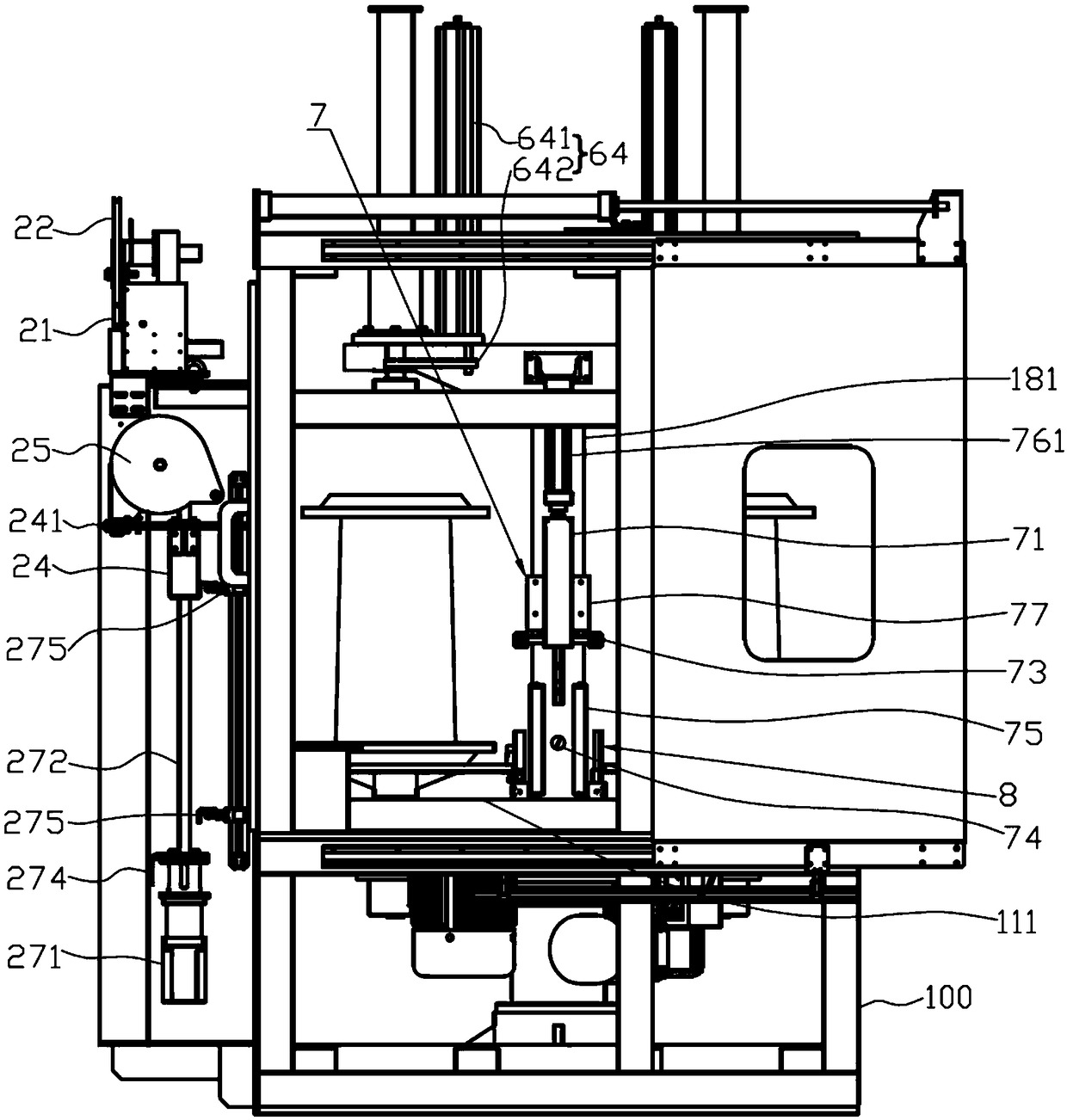

[0038] like figure 2 and 4 As shown, the wire support 2 includes a support 20, a first wire passing wheel 21 and a second wire passing wheel 22 installed on the upper part of the support 20, a tension swing rod mechanism 23 installed at the lower part of the support 20, and integrated on the wire guide block 24. The first wiring wheel 25 and two horizontally arranged second wiring wheels 26, the bracket 20 is provided with a wiring displacement driving mechanism 27 on one side of the bracket 20 close to the turntable type wire take-up device 1, and the wiring displacement driving mechanism 27 connects the wiring The guide block 24 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com