Long and thin column glass rod clamping device

A clamping device and glass rod technology, which is applied in the field of automatic production of optical lenses, can solve the problems of warping and deformation, not satisfying automatic clamping, etc., achieve the effects of small deformation at high temperature, solve the problem of optical lens falling, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

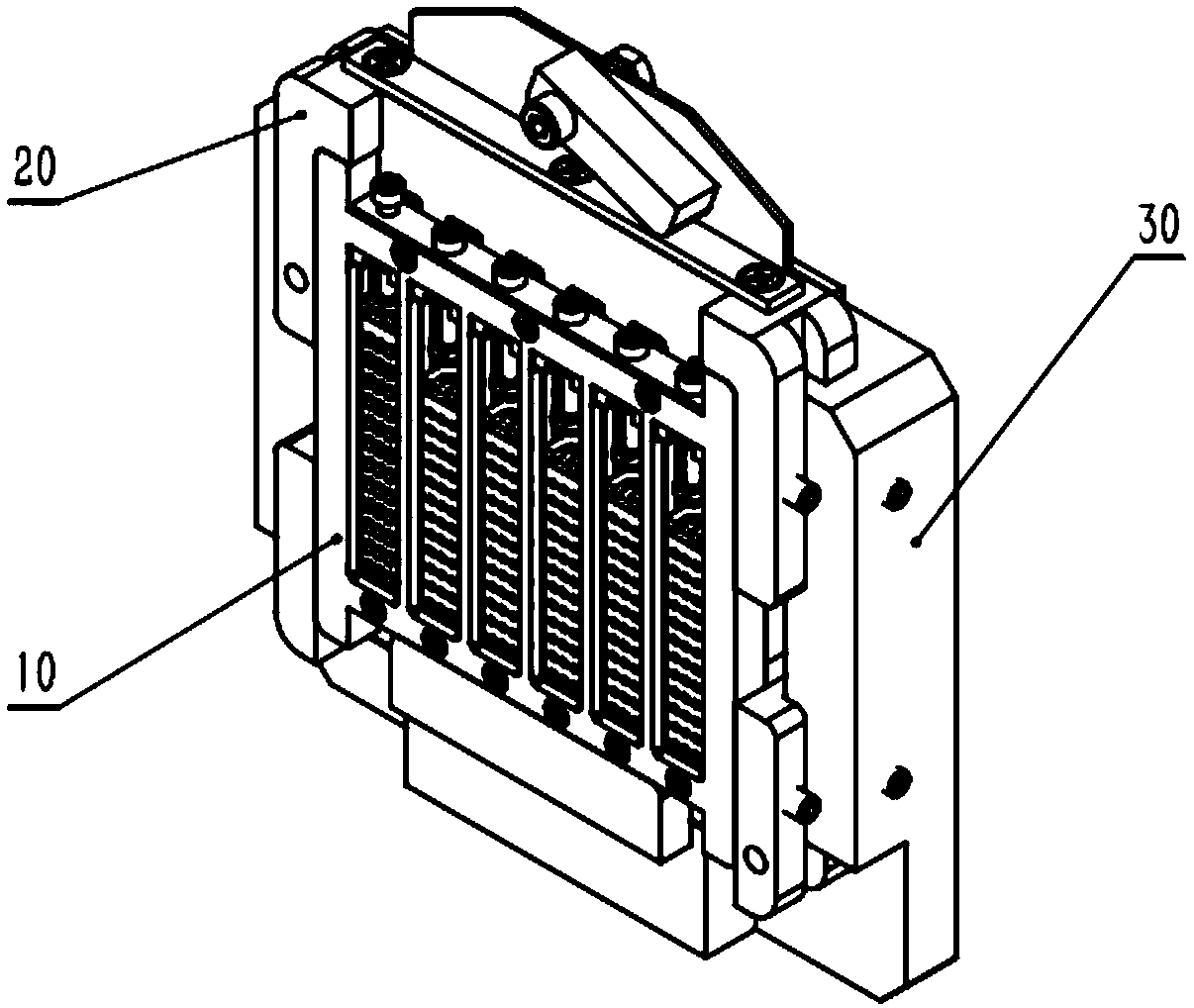

[0032] refer to figure 1 , a clamping device for a slender cylindrical glass rod, comprising a clamp 10 , a clamping fixture 20 and a fixing base 30 . The clamp 10 is installed on the clamping and fixing jig 20 , and the clamping and fixing jig 20 is installed on the fixing seat 30 .

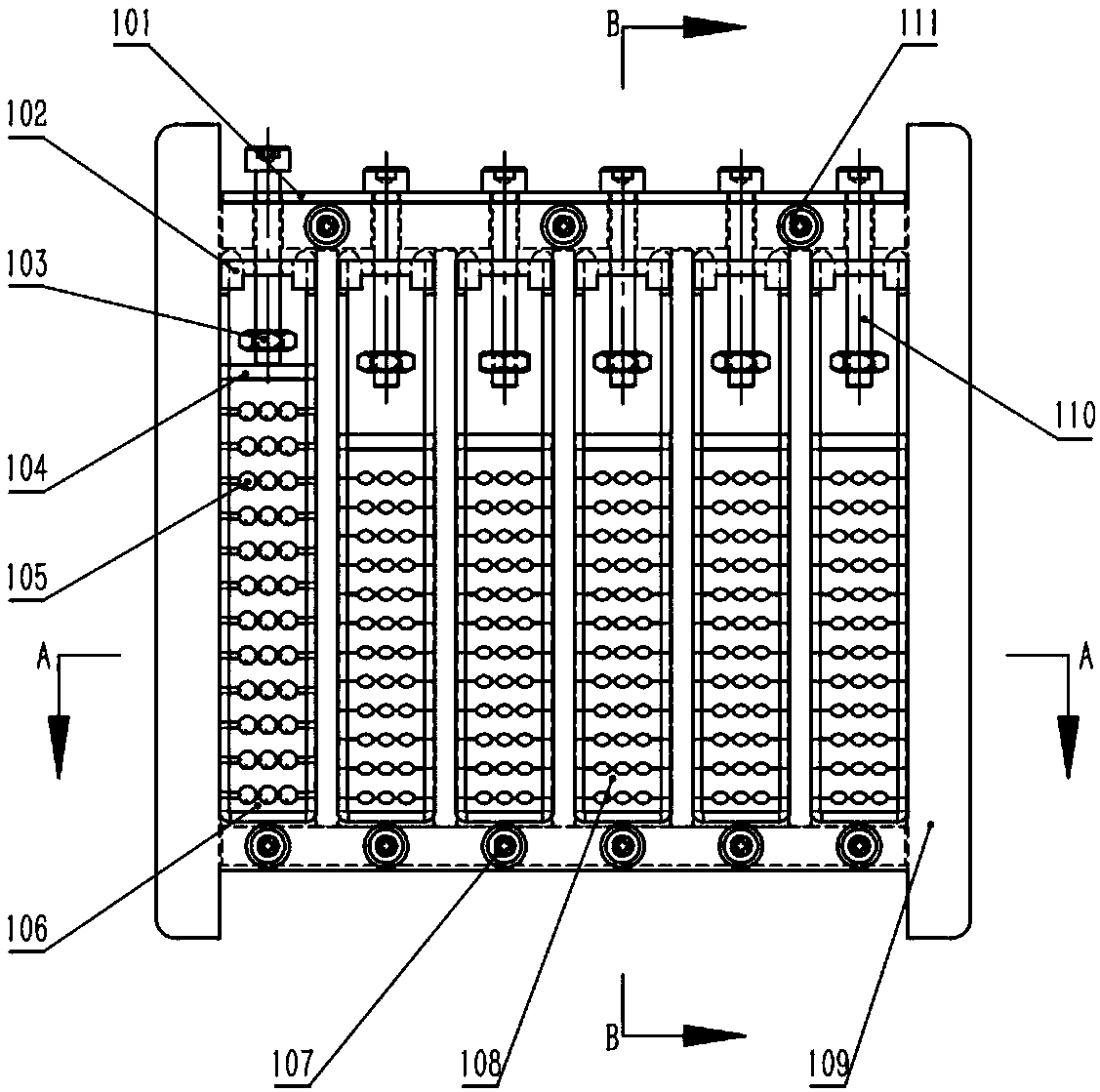

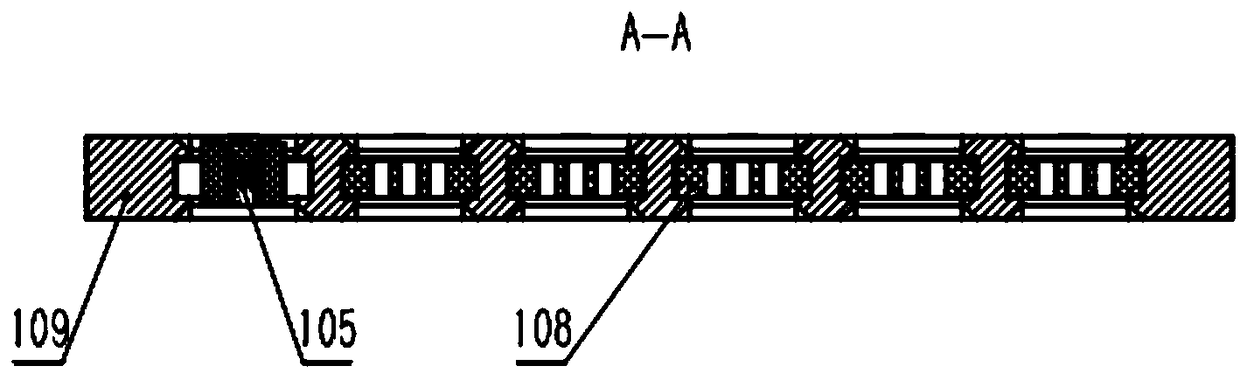

[0033] refer to figure 2 , image 3 , Figure 4 with Figure 5 , the clamp 10 includes an integrated bracket 109, and the integrated bracket 109 is integrally processed with 6 sets of guide grooves by wire cutting, and a single-sided clamping block 106 and a double-sided clamping block 108 are placed in the guide grooves. The block 106 and the double-sided clamping block 108 cooperate to clamp the optical lens 105, and the single-sided clamping block 106 and the double-sided clamping block 108 can slide freely along the guide groove; the top single-sided clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com