Single-sided adhesive with partial glue-free surface and production method thereof

A local glue-free, production method technology, applied in the direction of adhesives, film/sheet-like adhesives, etc., can solve the problems of low production efficiency, many processes, and many materials, and achieve the effect of fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

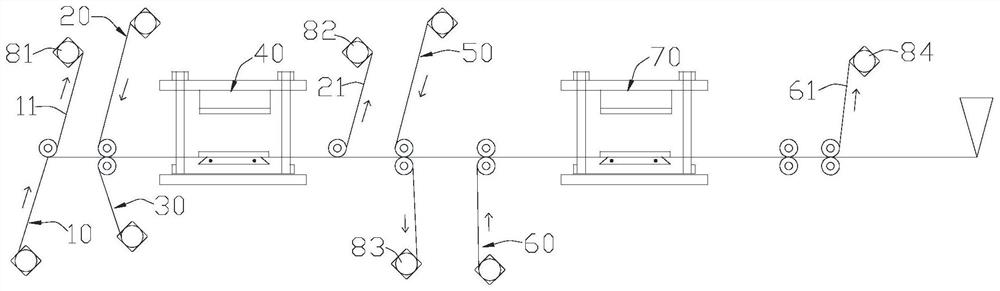

[0038] refer to figure 1 , the production method of the single-sided adhesive with partially glue-free adhesive surface of an embodiment of the present invention may comprise the following steps:

[0039] S1. Using the silica gel film 10 as the first backing, covering the rubber surface of the silica gel film 10 with the first release film 20 , and covering the non-adhesive surface of the silica gel film 10 with the protective film 30 as the second backing.

[0040] Wherein, the silica gel film 10 is made of silica gel-based materials, and the protective film 30 corresponds to an acrylic film made of acrylic rubber-based materials. The subsequent process is simplified by utilizing the detachable property of the two mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com