Rapid home towel drying disinfecting device

A rapid drying and disinfection device technology, which is applied to household clothes dryers, disinfection, washing devices, etc., can solve the problems of slow drying speed and achieve the effect of increasing drying speed and accelerating air convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

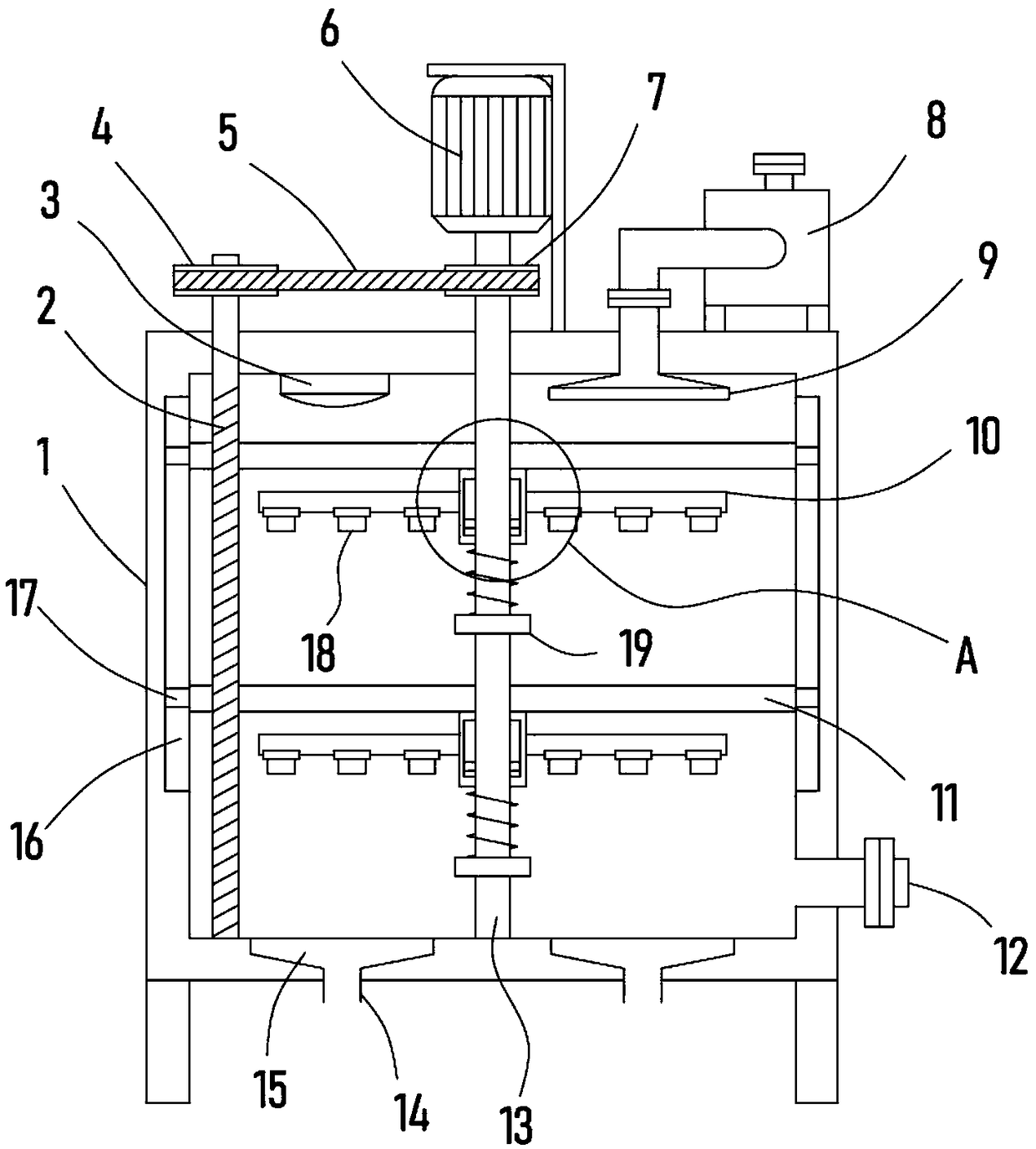

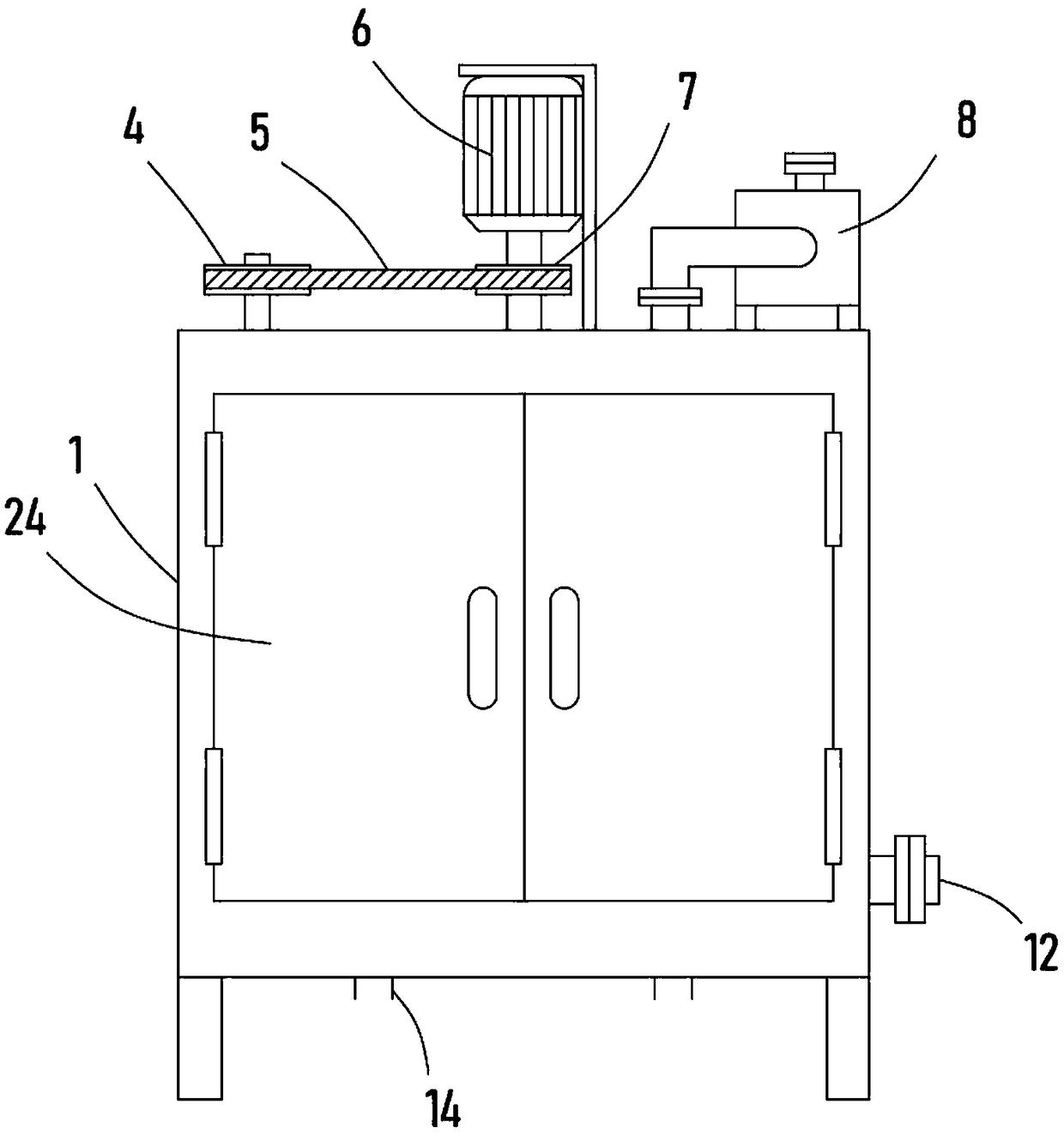

[0023] see Figure 1-5 , a device for quickly drying and disinfecting household towels, comprising a drying box 1, a forward and reverse motor 6 is fixedly installed on the top of the drying box 1, and the output shaft of the forward and reverse motor 6 is coaxially fixed and extends to the inside of the drying box 1. The drive shaft 13, the forward and reverse motor 6 can alternately carry out forward and reverse rotation, and then realize the forward and reverse rotation of the drive shaft 13 alternately.

[0024] A hot air blower 8 is fixed on the top of the drying box 1, and the air outlet of the hot air blower 8 is connected with an air jet disc 9 located in the drying box 1, and the hot air generated by the hot air blower 8 is sprayed into the drying box 1 through the air jet disc 9 to realize The inside of drying box 1 is full of hot air.

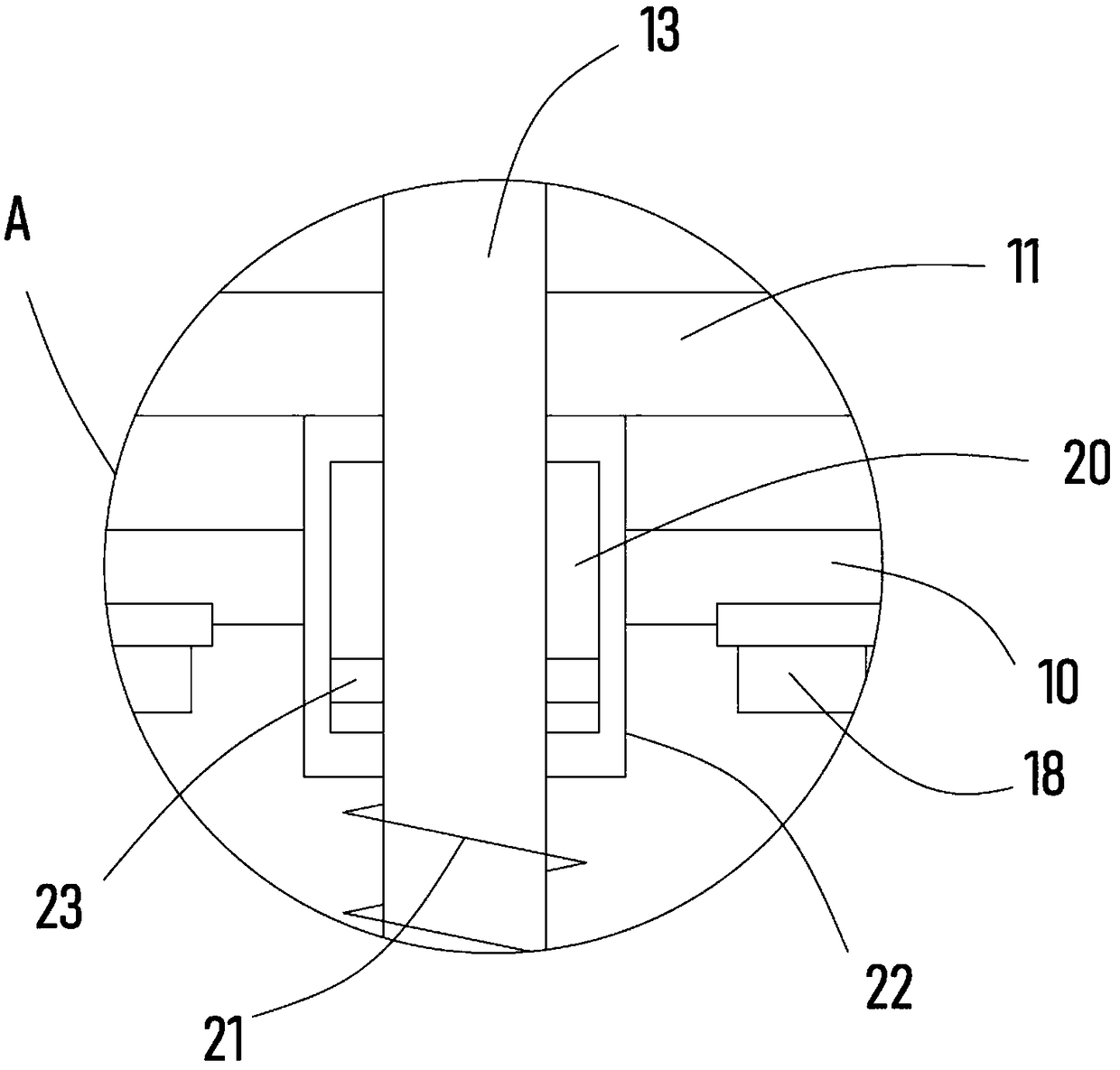

[0025] The drive shaft 13 is synchronously rotated and connected with two transmission sleeves 22, and the side wall of each trans...

Embodiment 2

[0029] On the basis of Embodiment 1, in addition, in the drying box 1, the rotating type is vertically provided with a lifting screw 2 threadedly connected with the pressure plate 11, and the upper end of the lifting screw 2 is sleeved and fixed with a driven pulley 4, and the driving shaft 13 The upper sleeve is fixed with the driving pulley 7 connected with the driven pulley 4 through the transmission belt 5, the driving shaft 13 drives the driving pulley 7 to rotate, and the driving pulley 7 drives the driven pulley 4 to rotate through the transmission belt 5, and then Realize the rotation of lifting screw mandrel 2.

[0030] Further, the drive shaft 13 is sleeved with a fixed limit cover plate 19, and the upper and lower ends of the drive shaft 13 are movably sleeved with limit springs 21 respectively fixed on the bottom end of the transmission block 23 and the upper surface of the limit cover plate 19. The positive and negative rotation of the reversing motor 6 realizes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com