Dyeing process of all-polyester chiffon fabric

An all-polyester and chiffon technology, which is applied in the field of chiffon fabric dyeing, can solve the problems such as the inability to improve the blackness of chiffon fabric, the reddish light of the finished product, and the deterioration of visual perception, so as to improve the coloring rate and improve the The effect of blackness, dry rubbing fastness and wet rubbing fastness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

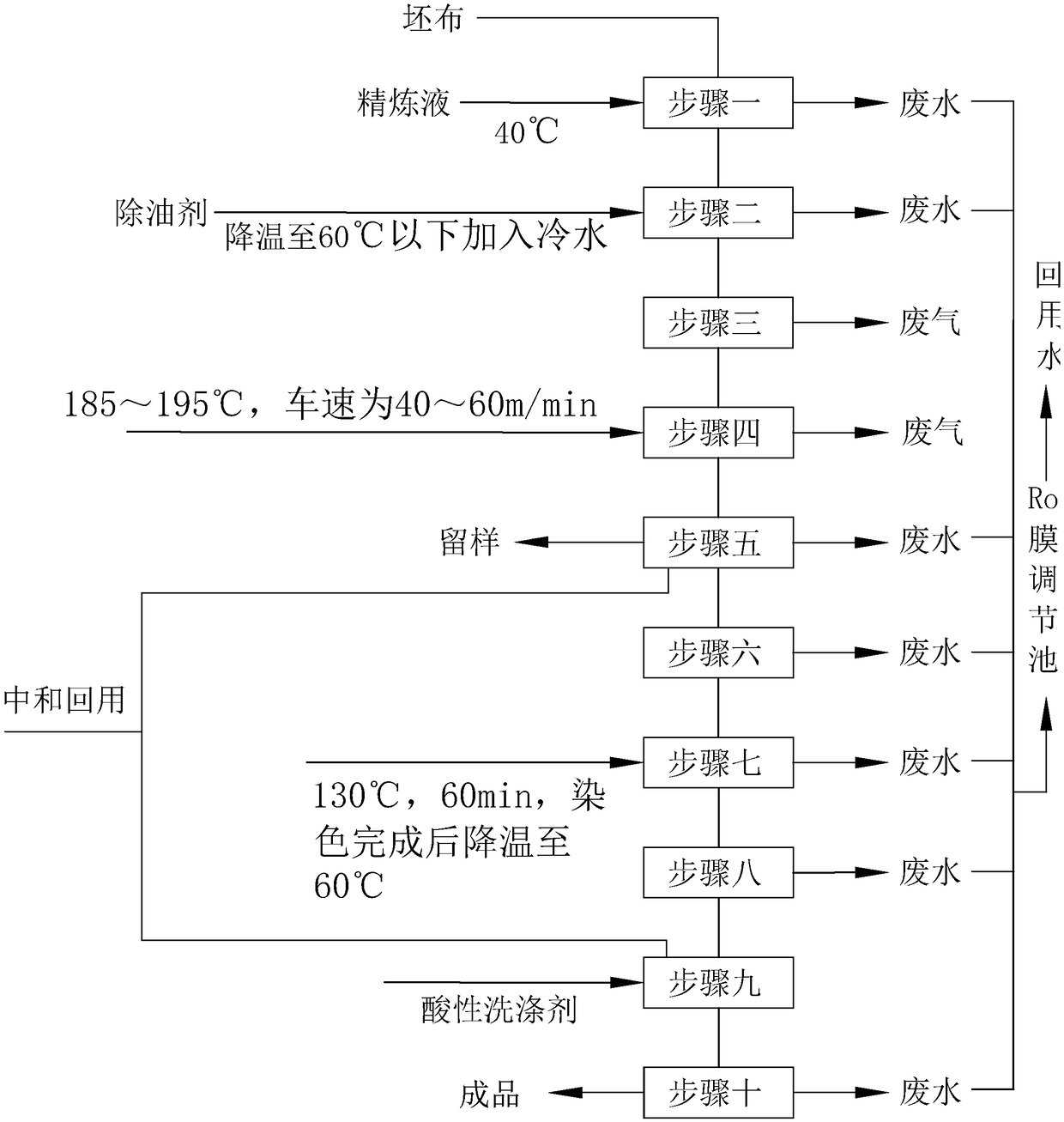

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] A kind of dyeing process of full polyester chiffon cloth, such as figure 1 shown, including the following steps:

[0041] Step 1: Put the gray cloth into the refining machine for open-width refining;

[0042] Step 2: pre-shrinking the gray cloth treated in step 1;

[0043] Step 3: using a dryer to dry the gray cloth treated in step 2;

[0044] Step 4: Use a sizing machine to pre-size the gray cloth processed in step 3;

[0045] Step 5: Using an alkali weight reduction machine to carry out alkali weight reduction treatment on the gray cloth treated in step 4;

[0046] Step 6: Use clean water to clean the remaining oil, polyester debris and polyester oligomers on the gray cloth treated in step 5;

[0047] Step 7: use the dyeing machine to spray the dyeing agent on the gray cloth treated in step 6 to dye the gray cloth;

[0048] Step 8: Cover the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com