Safe braking method of full-balance steel wire rope winch lifting type vertical ship lifting machine

A technology of balancing steel wire ropes and vertical ship lifts, which is applied in vertical lifting ship machinery, ship lifting devices, buildings, etc., can solve the problems of shock and vibration of main lifting equipment, affecting the service life of equipment, and inability to release internal stress effectively and timely. To achieve the effect of prolonging the service life and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0031] Example.

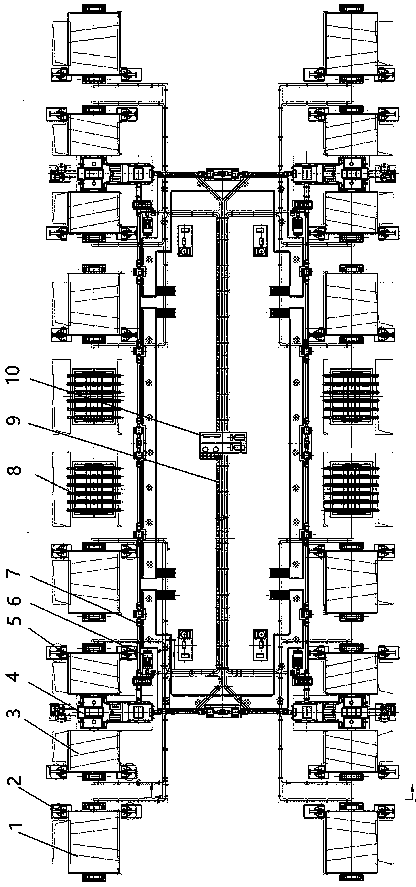

[0032] Such as figure 1 As shown, in this embodiment, the fully balanced steel wire rope hoisting type vertical ship lift includes 8 safety drums 1, 8 torque drums 3 and 4 reducers 4; 8 torque drums 3 are decelerated The device 4 and the synchronous shaft system 7 are connected in series to ensure rigid synchronization while the 4 motors 6 are synchronous; the 8 safety drums 1 are independent structures without external power drive; the main lifting system also includes 4 sets of pulley blocks 8, which are used to To bear part of the weight of the bearing box.

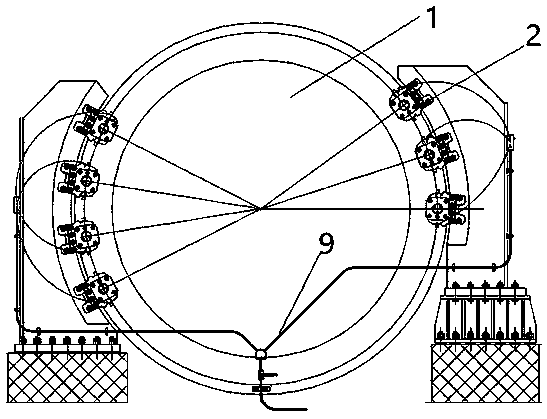

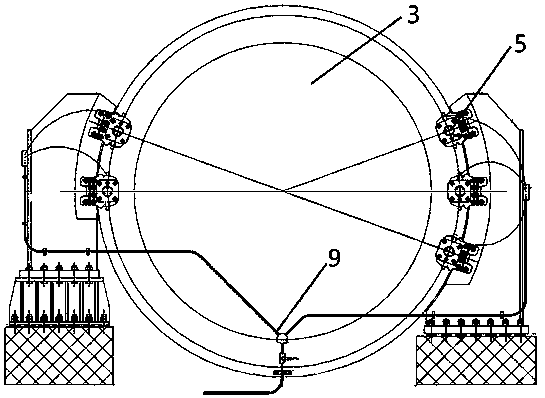

[0033] Such as figure 2 As shown, in this embodiment, 7 pairs of No. 1 safety brakes 2 are set on the safety reel 1, and the braking r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com