a floor heating

A floor and floor heating technology, applied in the field of floor heating, can solve the problems of easy moisture loss in the air, unfavorable body maintenance, and easy loss of water in the human body, etc., and achieve the effect of simple structure, long service life and high floor heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

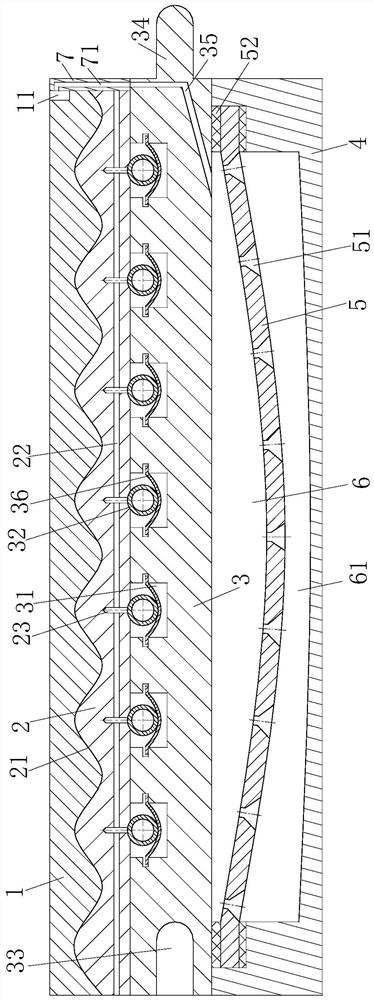

[0018] use figure 1 A floor heating floor of the present invention is described as follows.

[0019] The floor heating floor in the present invention is the abbreviation of the floor heating floor with air humidity adjustment function. figure 1 up, down, left, and right.

[0020] Such as figure 1As shown, a floor heating floor according to the present invention includes a wooden floor 1, a heat conducting layer 2 is arranged under the wooden floor 1, and wavy stripes 21 are provided on the upper surface of the heat conducting layer 2 and the lower surface of the wooden floor 1; the heat conducting layer 2 A mounting bracket 3 is provided below, and several square grooves 31 are arranged on the mounting bracket 3, and a heating pipe 32 is arranged in each square groove 31, and a tenon 33 and a tenon 34 are respectively provided on the left and right sides of the mounting bracket 3; The bottom of the mounting bracket 3 is provided with a base 4; the inside of the base 4 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com