Fullerene-containing quilt filler and preparation method thereof

A fullerene and filler technology, which is applied in the manufacture of rayon, single-component polyester rayon, chemical characteristics of fibers, etc., can solve the problems of poor moisture absorption and air permeability, single function, etc. The method is simple and the effect of excellent health care performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

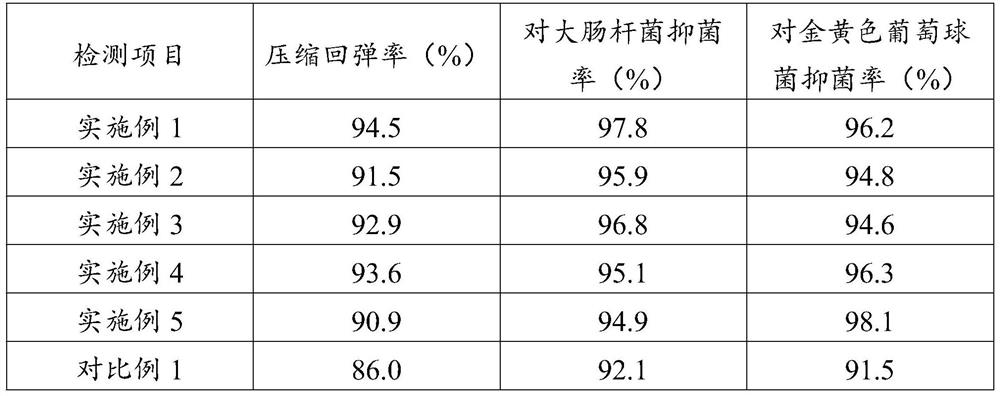

Examples

Embodiment 1

[0036] Fullerene-containing quilt filling includes: polyester fiber 90g, fullerene (C60) 0.1g, sandalwood powder 1g, chitin 3g, walnut oligopeptide powder 2g, millet oligopeptide powder 2g, citrus extract 3g , banana extract 3g, kiwi fruit extract 4g, wine 5g, alginate 3g, silk protein 2g, hydrophilic compound (amino acid) 4g.

[0037] The preparation method of the above-mentioned fullerene-containing quilt filler is as follows:

[0038] (1) take each raw material according to the weight of the quilt filler containing fullerene, and set aside;

[0039] (2) Stir and mix walnut oligopeptide powder, citrus extract, banana extract and kiwi fruit extract evenly, then mix with fiber, sandalwood powder, chitin, millet oligopeptide powder, wine and fullerene at a speed of Stir for 40 minutes under the condition of 600r / min and mix evenly to obtain mixture A;

[0040] (3) The mixture A is put into the extruder and extruded to obtain the masterbatch;

[0041] (4) Stir the masterbatch...

Embodiment 2

[0044] Fullerene-containing quilt fillings include: polyester fiber 95g, fullerene (C60) 8g, sandalwood powder 2g, chitin 4g, walnut oligopeptide powder 3g, millet oligopeptide powder 3g, citrus extract 6g, Banana extract 5g, kiwi fruit extract 7g, wine 9g, alginate 5g, silk protein 5g, hydrophilic compound (sodium sulfonate) 5g.

[0045] The preparation method of the above-mentioned fullerene-containing quilt filler is as follows:

[0046] (1) take each raw material according to the weight of the quilt filler containing fullerene, and set aside;

[0047] (2) Stir and mix walnut oligopeptide powder, citrus extract, banana extract and kiwi fruit extract evenly, then mix with fiber, sandalwood powder, chitin, millet oligopeptide powder, wine and fullerene at a speed of Under the condition of 800r / min, stir for 60min and mix evenly to obtain mixture A;

[0048] (3) The mixture A is put into the extruder and extruded to obtain the masterbatch;

[0049] (4) Stir the masterbatch,...

Embodiment 3

[0052] Fullerene-containing quilt fillings include: 93g silk fiber, 5g fullerene (C70), 1.5g sandalwood powder, 3.5g chitin, 2.5g walnut oligopeptide powder, 2.5g millet oligopeptide powder, citrus Extract 3.5g, banana extract 3.5g, kiwi fruit extract 5.5g, wine 7g, alginate 4g, silk protein 3.5g, hydrophilic compound (amino acid) 4.5g.

[0053] The preparation method of the above-mentioned fullerene-containing quilt filler is as follows:

[0054] (1) take each raw material according to the weight of the quilt filler containing fullerene, and set aside;

[0055] (2) Stir and mix walnut oligopeptide powder, citrus extract, banana extract and kiwi fruit extract evenly, then mix with fiber, sandalwood powder, chitin, millet oligopeptide powder, wine and fullerene at a speed of Stir for 40 minutes under the condition of 600r / min and mix evenly to obtain mixture A;

[0056] (3) The mixture A is put into the extruder and extruded to obtain the masterbatch;

[0057] (4) Stir the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com